High Quality Non Asbestos Free Calcium Silicate Boards

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Calcium Silicate Boards) Description

Can be used in washrooms as the ceiling, partition and backer boards. Additionally, Due to the features of fire prevention, thermal insulation, mildew proof and moisture proof, Bestinboards are also applicable to places where high security is needed.

2,Main Features of the (Calcium Silicate Boards)

Product Features:

1.Fire-retardant

2.Thermal-insulated

3.Mildew proof

4.Moisture proof

5.Sound insulated

6.Low moisture and water absorption

7.100% asbestos free and other hazardous substances.

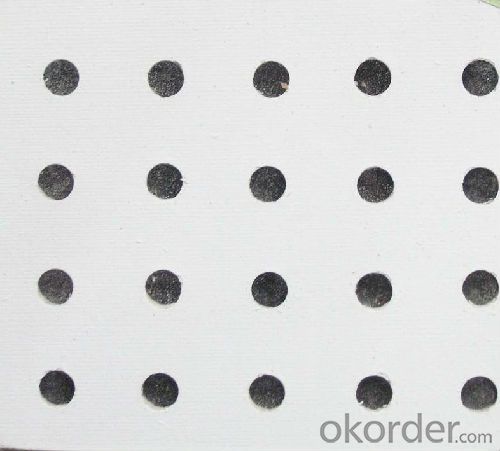

3,(Calcium Silicate Boards) Images

4,(Calcium Silicate Boards) Specification

| Size | Standard Size | Size:1220*2440*4/6/8/9/10/12/15mm |

| Appearance | Surface | Surface:Un-Sanded/Sanded/Polished; |

| Edge | Square/Recessed/ | |

| Physical Properties | Density | 1.2-1.3g/cm3 |

| Bending Strength | Cross > 16Mpa Parallel 60-70Mpa | |

| Moisture Movement | <0.20% | |

| Water Absorption | < 0.1% | |

| Water Contain | <6%(Under EMS condition) | |

| Thermal Conductivity | 0.12-0.15 w/(m •k) | |

| Non-combustibility | GB 8624-2006 Grade A1,CE EN 12467:2012 Grade A1 | |

| Water Impermeablility | Traces of moisture appeared on the under surface of the sheet,but no formation of drops of water on the underside of the sheet after 24 hours. | |

| Freeze-thaw | Not have cracking and layering after freeze-thaw cycles 25 times. | |

| Application | Interior Ceiling,Interior Patition, Bottom Liner | |

| Products Warranty | More than 20 years |

| Raw Material | Content |

| Cement | 44 % |

| Quartz | 44 % |

| Natural Fiber | 8 % |

| Suspension | 4 % |

| Composition of Finished Product | Content |

| Crystalloid of Calcium Silicate | 52% |

| Quartz | 30% |

| Calcium Carbonate | 10% |

| Cellulose | 8% |

5,FAQ of (Calcium Silicate Boards)

Package

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing.

Trade Term

1. Payment: T/T

2 .Lead time: Samples:15 Working days;

3. Shipping freight are quoted under your requests.

4. Shipping port: Foshan,Guangzhou or Shenzhen port, Mainland China.

5. Discounts: discount based on the order quantity.

Certificate

Products are Calcium Silicate Board (Fiber Cement Board), exterior wall plate, Facade Board and lining board, etc. Our products have passed ISO certificates. CE, TUV Certificates are on progress.

- Q:What is the specific difference between the silicate board and the calcium silicate board?

- Silicon calcium board was first used in high temperature furnace insulation. Such as "in order to improve the quality of shaft kiln clinker material, easy to coal blending and reduce clinker burning coal consumption, we must strengthen the kiln kiln body insulation.Often the practice is to use the internal insulation method, refractory layer, the total thickness of the insulation layer should be ≥ 650mm, near the kiln wall should be added ≥ 60mm calcium silicate board or aluminum silicate fiber mat ".

- Q:Calcium silicate board benefits and disadvantages?

- Advantages of calcium silicate board: 1, good fire performance: calcium silicate board is not combustible A-class material, if a fire occurs, the plate will not burn, it will not produce toxic smoke. 2, excellent waterproof performance: calcium silicate board has excellent waterproof performance, in the bathroom, bathroom and other places of high humidity, can still maintain the performance of stability, will not expand or deformation. 3, high strength: calcium silicate board high strength, solid and reliable wall, easy to damage rupture. 4, heat insulation, good sound insulation: calcium silicate board has a good thermal insulation properties, but also has a good sound insulation. 6, durable, long life: calcium silicate board performance is stable, Naisuan Jian, not easy to corrosion, it will not be moisture or insects and other damage, can guarantee a long service life.

- Q:Calcium silicate board is not gypsum board?

- Gypsum board fire and waterproof performance is weak, it is being replaced by calcium silicate board. In price, the price of calcium silicate board is also slightly more expensive than gypsum board, but it is worth the money.

- Q:Calcium silicate board above the watermark is how to cause

- Yellow whirring, and generally the reasons for the use of kraft paper fiber, dry after generally not anti-color, but I suggest you use sanded calcium silicate board, such problems will be less.

- Q:Should go to what unit inspection, please experience the peer talk about, thank you!

- There is a wall technical specifications, you can buy the bookstore to see, "JGJ / T157-2008 building lightweight strip wall technical regulations"

- Q:What are the extruded boards and calcium silicate board adhesives?

- Extrusion board on the requirements of the adhesive is relatively high, generally used to polymer mortar, two-component polymer mortar, and now some commercial resin powder instead of redispersible polymer powder Also has its advantages and disadvantages, its advantages are inexpensive, pre-bonding firm. Its disadvantages are slightly corrosive, late bonding is not very good. It is recommended to use two-component polymer bonded mortar (slightly higher cost) quality and reliable.

- Q:Silicon calcium board ceiling workers how much money a square meter

- Mineral wool board: seventy / square meter, light industry: twenty / square meter. Gypsum board flat top: one hundred three / square meter, light industry: twenty - five / square meter.

- Q:I need a tool that can cut calcium silicate board, Bo deep good, where can I buy Wuxi?

- We are Shijiazhuang company to buy their stuff of course good to buy, you can check online in your local dealer, their saw blade is good, our company has been with it

- Q:6.5 square machine room decoration ceiling how to count? Ceiling using calcium silicate board + steel keel, remove, block 8 nozzle

- I did not count the quota, I was calculated according to home improvement budget. I am a registered secondary construction division. Ceiling of the artificial are 40 square meters. Keel prices and silicon calcium board are not high, remove the block is to do some work, one day 100-200 yuan / person that kind.

- Q:Calcium silicate board commonly known as what

- Calcium silicate board as a new environmentally friendly building materials, in addition to the function of the traditional gypsum board, the more excellent performance of calcium silicate board and tide resistance, the advantages of long life, a large number of industrial and commercial applications in the ceiling ceiling and partitions, Home decoration, furniture liner, billboard liner, ship compartment board, warehouse floor, network floor and tunnel and other indoor works of the wall. It is a high-quality high-grade cement as the base material, and with natural fiber reinforced, the advanced production process molding, pressure, high temperature steaming and other special technology and made, is a good performance of the new building and industrial Plate of its products fire, moisture, noise, insect moth, durable. Is the ceiling, cut off the ideal decorative plate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Non Asbestos Free Calcium Silicate Boards

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords