Reinforced Fire Resistant Waterproof Wall Partition Ceiling

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

1.Calcium Silicate Board Drywall Specification.

| Convenient Construction | The Calcium Silicate Board can be constructed easily by nailing ,cuting and planing,and thus it becomes the first choice among home decoration materials. |

| Raw material | The Calcium Silicate board is characterized for lightness and high intensity,dryness operation, green environmental protect, convenient construction and good processing quality. |

| Size | 595x595 |

| 605x605 | |

| 1200x2400 | |

| 1220x2440 | |

| Thickness | 6.5,7,7.5,8,9,9.5,10,12,12.5, |

| Surface treatment | Non |

| Production capacity | 10,000m2/day |

Product Advantages:

2. Calcium Silicate Board of Ceiling & Wall Partition System.

System is a modern, non-load bearing and quickly assembled on site. The system consists of Gypsum Board screw fixed to lightweight galvanized metal sections and joint finished with drywall system is suitable for all internal applications for commercial and residential.

Exquisite, Modern and Adjustable

drywall system provides smooth, seamless and crack-free wall surface. Thanks to the distinctive property of gypsum Board, it allows easy further decoration by either painting or wallpaper work. Moreover, a renovation can be done easily without any disturbance of office building structure.

Durable and Standard Quality

Materials and accessories of wall system are manufactured by state of the art technology in accordance with international standards, such as, British Standard and The American Society for Testing and Materials. Customers therefore can be assured of safety, standard quality and high durabiltity of PRANCE Wall systems.

Lightweight, Easy to Install and Economic

wall weight much less than masonry partitions of comparable thickness, thus providing real savings in structural design. This enables quick and easy installation, and produces time and cost savings.

Main Product Features:

Specially Designed and Patented Materials of Gyproc

High quality galvanized frame metal sections of drywall system are manufactured by state of the art technology called drywall STEEL, to reinforce the cross section of metal sections. C-Stud is also specially designed to be easy when connected, which suits applications requiring extra strength or for length extension of C-Stud. Ready-punched holes from factory provide excellent incorporation of services.

Applicable to Various Usages as Required

wall system can be designed to suit various types of office application.

Office buildings requiring extra fine resistance, standard drywall system can provide a half-hour fire resistance. Other drywall Systems are also available to provide resistance up to 2 hours.

Other special properties such as heat insulation wall, high moisture resistant wall, acoustic wall, can also be provided by drywall system.

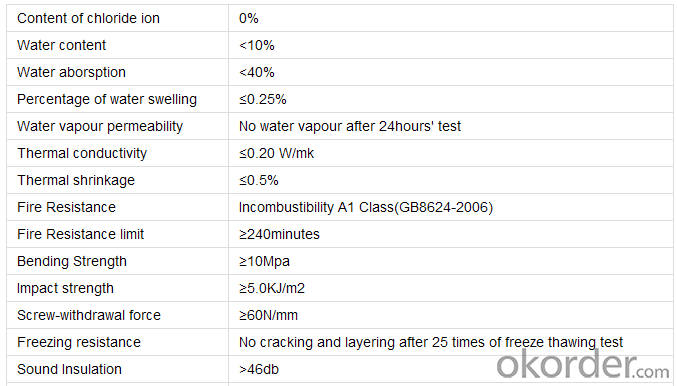

Product Specifications:

Images:

- Q:Calcium silicate board 6MM how much money one

- Calcium silicate board specifications are generally: 5mm 9MM, 12MM. 5mm in the general 20 yuan or so.

- Q:Living room light steel keel ceiling is gypsum board seal or calcium silicate board seal is better?

- Now the family is used in the gypsum board, and small-scale ceiling do not need to seal the wood floor.

- Q:Calcium silicate board can do the shape of the ceiling? If the figure can not, figure in the shape of what is generally used to do?

- Calcium silicate board is generally used to cut off rarely used to ceiling, you should be gypsum

- Q:What is the size and classification of calcium silicate board? How do we choose the specifications for their own calcium silicate board?

- According to the formula points asbestos and non-asbestos, according to the thickness of 4 to 30 mm, and then in accordance with the use of partition walls and ceiling, according to the density of low density, medium density, high density

- Q:Mineral wool board, silicon calcium board, aluminum slab plate is what is the difference between the use of the place, the more detailed the better.

- Mineral wool board and silicon calcium board are generally 600 * 600 specifications, used in offices and other small public places ceiling, aluminum slab board is more widely used, in addition to office and other public places, there are waiting room large space Use, and now also very popular in the home improvement in the kitchen bathroom with aluminum plate to do integrated ceiling.

- Q:Calcium silicate board surface putty Why crack?

- Usually in the board and board transfer place, very prone to cracking. And then the construction of such a transfer of the time, we must do anti-cracking treatment. If cracking has occurred, it will need to be shoveled along the cracks, and then fill with a dry coating, while the bandage to play a role in anti-cracking.

- Q:Decoration problem: a calcium silicate board about how many customers want me to calculate the weight. The Trouble trouble trouble.

- 1220 * 2440 * 6 Calcium silicate board normal weight at 22kg. 6 refers to the thickness of the ceiling now more than 5%, 5% is generally 18kg. Under the premise of fixed specifications, mainly depends on the bulk density. However, due to the manufacturers of different recipe technology, bulk density will be a little different. Please add points.

- Q:Two layers of calcium silicate board in the middle of what kind of sound insulation board

- Calcium silicate composite rockwool sound insulation board, but now with less, mainly out of environmental protection, the use of area considerations.

- Q:Does the apartment use silicon calcium board to make the wall right?

- With silicon calcium board to do the wall both advantages and disadvantages, the following talk about my view of it Calcium silicate board advantages: 1, good fire performance: calcium silicate board is not combustible A grade material, if a fire occurs, the plate will not search will burn, it will not produce toxic smoke. 2, excellent waterproof performance: calcium silicate board has excellent waterproof performance, in the bathroom, bathroom and other places of high humidity, can still maintain the performance of stability, will not expand or deformation. 3, high strength: calcium silicate board high strength, solid and reliable wall, easy to damage rupture. 4, heat insulation, good sound insulation: calcium silicate board has a good thermal insulation properties, but also has a good sound insulation. 6, durable, long life: calcium silicate board performance is stable, Naisuan Jian, not easy to corrosion, it will not be moisture or insects and other damage, can guarantee a long service life.

- Q:Calcium silicate board why wet weather will appear scarred

- Improper storage of the plate: the plate in the installation and construction of wet moisture, resulting in deformation, in the construction of natural dry conditions, resulting in contraction, cracks.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Reinforced Fire Resistant Waterproof Wall Partition Ceiling

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords