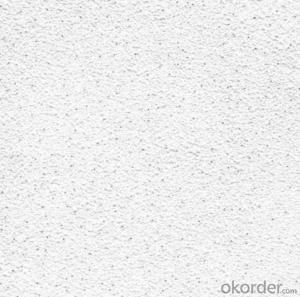

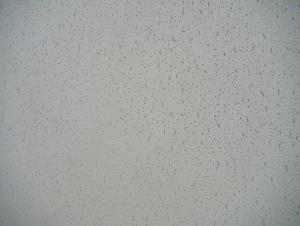

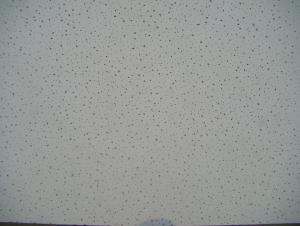

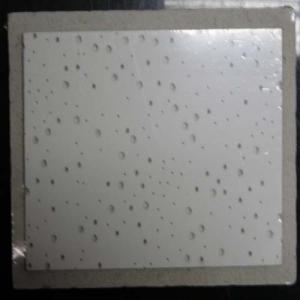

Mineral Fiber Ceiling Tiles with Special Sand Textures

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Mineral Fiber Ceiling ) Description

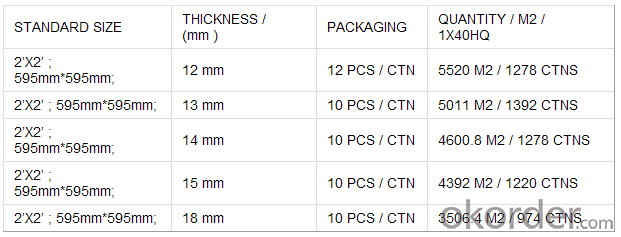

595mm*595mm; 1195mm*1195mm; 2’X2’; 2’x4’;

Thickness Range: 8mm – 18mm

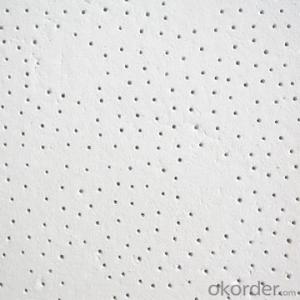

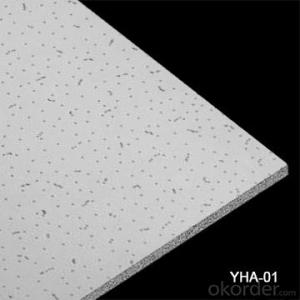

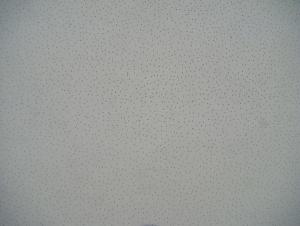

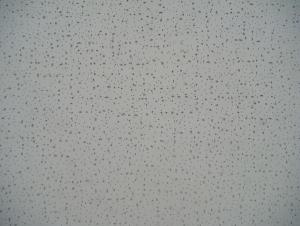

Available Textures:

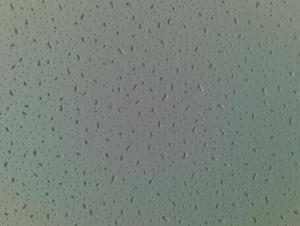

Astral Series; Perforated Series; Fissured Series; Sand Series.

Edge Detail: Square, Tegular

Technical Data:

Density (kgs/m3): 260-320kgs/m3

Noise Reduction Coefficient (NRC): ≥0.45

Humidity Resistance: ≥85%

Fire resistance: Class A Qualification

Light reflect: 0.60-0.80

2,Main Features of the (Mineral Fiber Ceiling )

Offices, Conference rooms, Corridors, Super Malls, Hospitals and other Public areas

Product Performance:

High absorption & sound insulation;

High humidity & fire resistance;

High light reflection;

Environment-friendly;

3,(Mineral Fiber Ceiling ) Images

4,(Mineral Fiber Ceiling ) Specification

5,FAQ of (Mineral Fiber Ceiling )

Main Advantage:

1. Use high quality mineral wool as the main raw material, asbestos free, won’t appear needle dust, which might enter human body through the respiratory tract.

2. Use the expansion perlite, which has the function of fire resistance and heat insulation, can effectively reduce the cooling & heating fee. It meets the demand of saving energy and reducing consumption.

3. Use composite fiber and special coating, greatly improving fighting force and resistance to deformation ability.

- Q:Example: gypsum decorative plate specifications for the 500 * 500mm, the patchwork width of 2mm, the loss rate of 2%, calculated 10m2 need to use gypsum plate number. Solution: gypsum decoration

- To determine the length and width of the area to know the need for a few gypsum board.

- Q:Outside the wall decoration board

- 1. Insulation insulation, energy saving Jin Kima metal insulation decorative panels with excellent thermal insulation properties, and the traditional wall panels and other building materials, compared with excellent cold insulation properties. Greatly reducing the heating and cooling energy consumption, thus saving energy expenditure. Jin Kima metal insulation decorative board products cost-effective, in the metal wall insulation decorative panels and other materials products show an absolute advantage. (0.15W / mk) 75mm, fiber cement board (0.17W / mk) 85mm, cement mortar (1.3W / mk) 650mm; and the thermal insulation coefficient and the same insulation effect material thickness comparison of autoclaved aerated concrete block Jin Kima metal insulation decorative plate thickness of 16mm, thermal conductivity was 0.020W / mk, far better than other insulation materials.

- Q:Xps insulation one decorative plate composite process

- Installation process ??1. Requirements for the grassroots level ??Insulation decorative plate special layered structure, to ensure that the insulation board itself is strong and smooth. Normal installation of insulation board when the grass-roots should meet the standard plaster, no cracking, can not afford to powder, can not afford to sand, not hollow, not peeling, surface smooth, vertical vertical, yin and yang angle vertical. ??As the grass-roots wall slightly concave and rough can be adjusted through a special mortar, so the decorative insulation board on the grass-roots flatness and finish requirements are relatively low, and the treatment is relatively simple. This is the metal paint, fluorocarbon paint and other high-grade paint in order to achieve imitation aluminum effect, at the use of more than ten processes to deal with grass-roots formation of a sharp contrast. ??2. Paste ??Insulation decorative plate for the light board, the product weight per square meter is only 8-10 kg, than the field operations to the national EPS / XPS thin plaster system, the overall weight is still small, so only special mortar will be directly pasted to the wall , Can reach the required bonding strength requirements. ??2 anchor ??To completely eliminate the insulation of the decorative plate layered peeling phenomenon, improve the overall safety of the insulation board, the use of anchors, tighten the decorative layer, and once again the insulation decorative panels and walls firmly connected together. ??This double-type fixed mode, for the high-rise building facade decoration provides a perfect guarantee. ??3 seam processing ??In the field to install insulation decorative panels, between the two plates reserved between the 5mm-10mm wide seam. When the mortar at the bottom of the finished plate is dried, the foam is embedded in the joint and the whole seam is filled with weather-resistant sealed silicone.

- Q:Seems to be a drawing software, have to understand the details of the talk, thank you!

- You can also select the graphics, the mouse on the lower right corner of the pattern, the mouse becomes a double arrow when you can drag the mouse to zoom in or out of the image.

- Q:Tunnel decoration board, inorganic pre-coated plate which is good? anxious

- Domestic inorganic pre-coated plate to do the best business

- Q:Metal carved exterior wall insulation decorative board application prospects?

- Now the external wall insulation decorative board is a popular trend It is nice to tailor to the needs of the customer

- Q:Li Mei diatom decorative plate more than one square meter

- Li Mei diatom integrated decorative plate with a convenient decoration, insulation noise, moisture-proof fire, colorful, many colors, long life and so on

- Q:What kind of decorative plate is the nail on the wall?

- Jin Kima metal insulation decorative board is a kind of high pressure, earthquake, moisture, water, fire, noise, insulation, low thermal conductivity, beautiful, durable, energy saving, simple construction, environmental protection and so on a series of excellent performance of the new Building materials, can be widely used in schools, hospitals, hotels, railway stations, villas, the old building appearance transformation, mobile board room, post booths, kiosks, power facilities, light steel structure,

- Q:Mercedes-Benz c-class interior decoration board how to disassemble

- Mercedes-Benz R350 door is a screw plus expansion buckle way fixed, front door of the electronic control switch which has a screw, be careful to pry out the switch to disassemble.

- Q:Bamboo fiber integrated wall decorative plate is what structure

- 2017 is the beginning of the day with the United States with aluminum foil, foam layer, made of aluminum alloy, 2017 days of the United States integrated wall decoration materials used to upgrade to bamboo fiber, polymer waterproof fire materials, spar powder high temperature suppression, Using high temperature coating or roller coating process, very environmentally friendly and beautiful, with a very good market demand.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mineral Fiber Ceiling Tiles with Special Sand Textures

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords