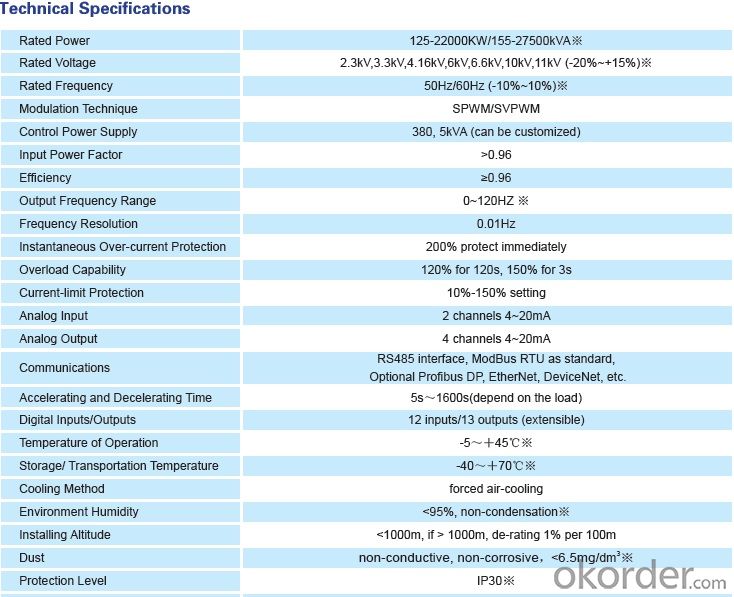

Medium Voltage Drive VFD 440KW 3.3 KV HIVERT-Y 3.3/096

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Perfect Power Output Section

The HIVERT general MV VFD adopts the power cells connected in series and voltage overlapping method (i.e. Power cells multi-level cascade technology), it can output the perfect PWM sinusoidal waveform (see Figure 2 and Figure 3). It has the following advantages:

1. No need for the additional output filter

2. Directly driving general synchronous or asynchronous motor

3. No de-rating operation on the motor

4. No dV/dt stress on the insulation of motor and cables

5. No torque ripple, extending service life of motors and mechanism

6. No cable length restriction within the acceptable voltage drop.

The general MV VFD has the following protection functions and features:

The RMVC 5100 provides speed and/or torque control for Solution for a wide range of industries

motor-driven applications in the medium and high power

range from 200kW to 14 MW at motor voltages from 3.0kV

to 13.8 kV.

It is available with air cooling in the lower power range and

with optional water cooling in the medium to high power

range. RMVC 5100 drives are also available mounted

within a customised container, with self-contained sealed

cooling systems, providing the highest IP class ratings for

hostile environments as well as providing greater

convenience and ease of installation and commissioning.

- Q:Is the speed of the motor controlled?

- Armature for the cast steel made of cylindrical structure, which is connected with the squirrel cage induction motor shaft, commonly known as active part; Pole made of claw-shaped structure, mounted on the load shaft, commonly known as the moving part. The active and slave parts are mechanically free of any contact.

- Q:The laptop power adapter is hot

- Notebook power adapter in the power after the use of hot is a normal phenomenon, do not worry, no danger, it will not explode. The length of this time does not matter, in the use of one or two hours will become very hot, but will always keep this temperature. And the notebook's power adapter shell are high temperature, will not burn. Notebook power adapter in addition to hot, you may hear the sound, the sound is not, very small. This sound is not a big problem, it is the power adapter power after the power filter sound, so plug in the plug after. Any power adapter basically has a sound. You can listen carefully, the surrounding environment is particularly quiet when you can hear. Power adapter is a transformer, inside the transformer coil in the AC will produce Zizi sound. Some power adapter use a long time will have this sound, but no big problem, you can continue to use. As long as the sound is not high outrageous do not control. Laptop power adapter hot and sound basic are considered normal, unless the temperature is too high or even damage to the shell or the sound is very obvious, this is a problem. The general does not affect the use of the adapter bad to buy a can. Notebooks have to protect the isolation circuit, do not worry about damage to the notebook.

- Q:The inverter is running independently

- Frequency conversion regulator is the application of frequency conversion technology and microelectronics technology, by changing the motor operating frequency mode to control the AC motor power control equipment. The inverter is mainly composed of rectifier (AC variable DC), filter, inverter (DC variable AC), brake unit, drive unit, detection unit micro-processing unit and so on. The inverter will adjust the voltage and frequency of the output power supply according to the breaking of the internal IGBT, and provide the required power supply voltage according to the actual needs of the motor, so as to achieve the goal of saving energy and speeding.

- Q:My laptop can not use the power adapter, and can only use the battery, how is it ah,

- I have encountered the same problem, plug in the adapter, or use the battery power, the battery alarm, not the battery charge, the power adapter can not be used. But the power can charge the battery. If the power adapter alone, one will automatically shut down. Measure the adapter voltage normally. And then to get the computer city maintenance department, gymnastics, it is a simple question, the original power line in the circuit board on the solder joints are loose, that is, Weld, resulting in insufficient current, no wonder, off the machine can charge, boot can not charge, It shuts down. Spent 100 yuan. Business really black. I saw the repair. On the welding a few times OK. No wonder, once I suddenly shot about, the adapter can be used. Later, how to shoot not work. However, although spent 100, but my computer's heat silicone grease for the whole, the computer CPU temperature is not so high before. The beginning of the maintenance staff said that the power management chip may be broken, if the bad to more than 100, then, no bad, just contact the problem, welding also received me 100, really depressed. In fact, you can say good, if the contact problem, certainly below 100.

- Q:What is the number of parameters of the motor frequency of the Siemens inverter?

- It is best to provide the model of the inverter Oh!

- Q:What is the difference when using inverter frequency conversion ordinary motor and variable frequency inverter motor

- First of all you have to understand the difference between variable frequency motor and ordinary asynchronous motor. 1, inverter motor cooling fan is not connected with the motor spindle, is independent, the fan rotation from the motor speed, to ensure that the motor cooling.

- Q:Laptop power supply 20V 3.5A can use 20V 4.5A power adapter Mody, what impact?

- It's ok. As long as the voltage is appropriate on the line. Current value refers to the maximum current that can be output. How much depends on your computer. Or, with a big no harm, can only be better, if you can use a small, but a little longer charging time.

- Q:Yaskawa inverter reported base blockade what is the reason?

- Yasukawa compared garbage on the signal board on the small line of poor oxidation, and get like, this is a weak signal, and safety relays connected, do not use high-grade security circuit with a small line short, Yasukawa A 1000 factory is short for a long time after the oxidation of the base blockade

- Q:How can a variable speed multi - speed three - phase asynchronous motor be controlled by a frequency converter?

- With the inverter control, then you do not need multi-speed motor, because the inverter can directly control the motor speed, if the two together, the formation of a waste.

- Q:What is the application of variable frequency speed control?

- Frequency conversion is to change the power supply frequency, thus regulating the load, play a lower power consumption, reduce losses, extend the service life of the role. Frequency translation. Frequency conversion technology is the core of the inverter, through the conversion of the power supply frequency to achieve the motor speed regulation of the automatic adjustment of the 50Hz fixed-line frequency to 30-130 Hz change frequency. At the same time, also make the power supply voltage to adapt to the range of 142-270V, to solve the power grid voltage instability caused by electrical work problems. By changing the AC frequency of the way to achieve the AC control technology is called frequency conversion technology.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Medium Voltage Drive VFD 440KW 3.3 KV HIVERT-Y 3.3/096

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords