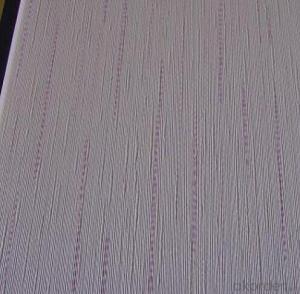

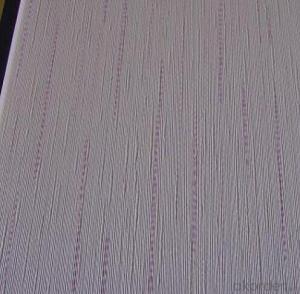

Manufacture Wood grain PVC Panel &PVC Door Panel&PVC profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC PANEL&PVC DOOR PANELS

Detail form:

Thickness | 5MM/5.5MM/6MM/7MM/8MM |

Width | 200MM/250MM/300MM |

Length | 5800MM/5950MM/3660MM |

Finish | Prining/High glossy/Transfer |

Typle | Flat/groove in middle |

Quality | high |

Loading | 20'ft/40'HQ container |

Materia | PVC |

Use | For wall or ceiling |

Certificate | "ROHS""."ISO9001:2000" ."brand for china building line" |

Weight | 1.8kg,2.1kg,2.3kg,2.5kg,2.8kg,3kg |

Fetures | wearing resistence, water proof, flame retarding, aging |

Proof | light in weight and easy to install |

Colors | Hundreds of colors available for surface treatment. |

Payment | T/T |

MOQ | 3000SQM |

Delivery Time | 15 days after the received deposit |

Packing | 10pcs/bundle,Shrink film,Cartone |

Port | Shanghai Port |

3.PVC Panel Specification:

(1Thickness:5mm,5.5mm,6mm,7mm,7.5mm,8mm,8.3mm,8.5mm,9mm,9.5mm,12mm.

(2)Width:250px,400px,500px,475px,625px,750px,1500px

(3)Length:as per customers requirements

(4)PVC%:40%,45%,50%

(5)Colours and patterns:hundreds of colours and patterns for you to choose,or according to your specific designs.

4.PVC Panel Application:

(1)Household ornament:wall and ceiling of indent independent housebathroom or kitchen.

(2)Public and management place:toilet of building and hall.

(3)Common office:ceiling of business place.

5.Feature:

1)Easily assembly,surface even,without gap when concatenated.

2)High intensity,corrode-resisting,aging-resisting,can be used more than 30 years.

3)Prevent fire,antibiotic,healthy and environmental.

4)The surface picture is clear and adhesive.

5)For ceiling and wall decoration.

6)More than 200 specification,3000 article picture,we can fit you many needs.

PVC DOOR

1.PVC DOOR SIZE:

1. PVC door panel (professional manufacturer)

(1).size: 1650px/1587.5px/500px*50px

(2).weight: 3kg-5kg

(3).pvc percent: 40%-60%

(4).widely used to hotel and household

2. PVC door Outer size:

Cutting: 147.5px*60px

No cutting: 300px*60px

Weight: 0.43 kg/m, 0.30 kg/m

3. PVC door Frame size:

120px*100px

Weight: 0.43 kg/m, 0.30 kg/m

4. PVC door Multi Panel size:

500px*50px

Weight: 4.1 kg/m2

2. PVC door application :

Our Plastic door can be used almost anywhere: Bathrooms, kitchens, bedrooms, lounges,

utility rooms, workshops, commercial premises, catering establishments, sports and leisure centers.

They are widely used for indoor decoration, for bathroom door, wardrobe door, drawer door, kitchen cabinet door...... cheaper and firmly, also easy getting and cleaning! waterproof, fireproof and environmental friendly.

3. PVC door Feature:

(1)High shrink surface, smooth without gap when concatenated;

(2)Fireproof, moisture-proof, mould-proof, waterproof, soundproof, soundabsorbing, light in weight and easy installation;

(3)For interior decoration, widely used to hotel decoration;

(4)The variety of colors and patterns;

(5)100% recyclable, hygienic and durable;

4. PVC door advantages :

(1).With wooden grain,variety of color changes,more modern design and personality to respond Environmental protection requirements.

(2).Its surface smooth and bright.Paint-free,to avoid the dissemination of poisonous gas against the terrible consequences to human health after using the decorative paint.

(3).Short work cycle,quick delivery time

(4).Advanced manufacturing processes,selection of high-quality raw materials to develop paint-free decorative materials,with a crash-resistant.No spontaneous combustion.Anti-moth-eaten.Moisture.Anti-corrosion.Drug-free. Tasteless.Pollution-free,etc advantage.

(5).Simple installation,Good maintenance

- Q:Bamboo flooring and PVC flooring which is good

- Bamboo flooring is made of bamboo. He can create a classic, beautiful, natural, elegant decoration style and Dongnuanxialiang are green products; pay attention to water, moisture, pest control, anti-ants maintenance.

- Q:Where do you have to sell the PVC board for the 2000x1200x20 specification?

- Very simple, you go to the sales outlets to ask chant! The The

- Q:What are the advantages and disadvantages of color steel tile and PVC tile?

- PVC tile is based on polyvinyl chloride resin (referred to as PVC) as the main raw material, supplemented by UV anti-ultraviolet agent and other chemical raw materials, the scientific ratio, with advanced technology. PVC tile, also known as plastic tile, is the replacement of color steel tile products. The use of multi-layer co-extrusion composite technology, the product surface covered with anti-aging layer, improve the weather resistance and color durability, the bottom of the wear-resistant layer. Has a good fire, corrosion resistance, weather resistance, non-asbestos ingredients, bright colors, environmental health. Is widely used in large-span door structure of the plant roof and wall, both to meet the light steel structure of the plant's anti-corrosion needs, but also save steel, reduce costs.

- Q:Bathroom cabinet pvc plate is solid wood particles board it

- General performance PVC resin is a white or light yellow powder, the relative density of 1.35-1.45. The soft and hard degree of the product can be adjusted by adding a plasticizer. The following are the same as the " Mechanical properties PVC has a high hardness and mechanical properties. And increased with the increase of molecular weight, but with the temperature rise. Hard PVC mechanical properties, and its elastic modulus up to 1500-3000MPa. While the soft PVC elasticity of 1.5-15 MPa. But the elongation at break up to 200% -450%. PVC friction in general, static friction factor of 0.4-0.5, dynamic friction factor of 0.23. The following are the same as the " Thermal properties of PVC heat stability is very poor, 140 ℃ began to break down, the melting temperature of 160 ℃. PVC linear expansion coefficient is small, with flame retardant, oxidation index of up to 45 or more. So in the processing process need to add heat stabilizer, to ensure product performance. The following are the same as the " Electrical properties PVC is a good electrical properties of the polymer, but because of its large polarity, electrical insulation than PP and PE. Dielectric constant, dielectric loss tangent and volume resistivity, resistance to corona is not good, generally suitable for low pressure and low frequency insulation materials. The following are the same as the " Environmental performance PVC can withstand most of the inorganic acid, alkali, salt, most organic solvents. Suitable for medicine, chemical anti-corrosion materials.

- Q:Pearl board pvc board distinction

- PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

- Q:What is the pvc board? Durable?

- PVC is a PVC, a plastic, waterproof good

- Q:Pvc board can not be posted on the wallpaper, can be used to how long

- Yes, but this material should only use self-adhesive

- Q:Soft pvc board how to install it? How is the market price?

- Pvc board ceiling construction construction process: the process of grass-roots clean → → → installation of hanging bar → installation of the main keel → installation of the keel → weak, integrated wiring laying → hidden inspection → installation of the keel and PVC board → finished product protection → sub-

- Q:The building codes where I live are based on NEC codes. They're really hard to understand as a non-electrician.

- Yes, PVC conduit will be fine, unless you're in a commercial or industrial application. Be sure to use grey PVC, although it costs a bit more. If you use white, some poor schlub (maybe me) will come along someday and cut through it thinking it's water (we always use white for water, yellow for gas, and grey for electricity).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Manufacture Wood grain PVC Panel &PVC Door Panel&PVC profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords