LC LOW CARBON FERRO CHROME FECR ALLOYS MANUFACTURER SUPPLY

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ferro Chrome

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

Chrome is mainly used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized. Micro-carbon ferro chrome is applied to making stainless steel, acid-resistant steel and heat resistant steel.

Specifications

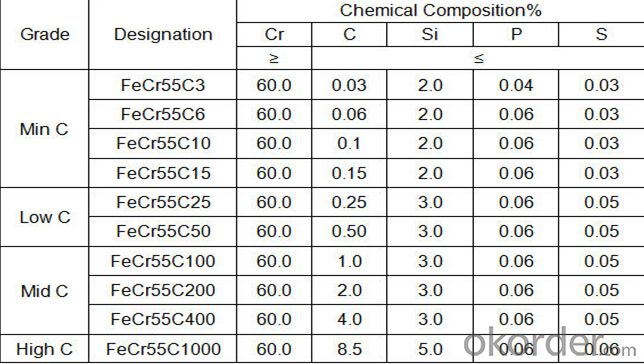

Low Carbon Ferro Chrome

1. Original manufacturer

2. The stability of the shipments

3. Free samples

4. Relatively lower cost

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

Specifications

1. Ferro chrome

1).Type;HC MC LC

2).Brand:FeCr67C6.0,FeCr55C600,etc

3).strict quality control

4).Factory price

2. High Carbon Ferro Chrome

Ferro Chrome

FeCr

1).ChemicalCompositions:Fe,Cr,C,Si,P,S

2).Type:High,Medium,low,MicroCarbon

3).FeCr67C6.0,FeCr55C600,etc

4).Improve antioxidation.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q:Printing requirements for cemented carbide

- Its disadvantages are: there are a small amount of pores and defects in the product, and the carbon content of the sinter will decrease.Hot isostatic pressing sintering in sintering with inert gas, liquid metal or solid particles as pressure transfer medium in each direction of the sintered body exert equal pressure, not even this can overcome ordinary hot pressing pressure is not uniform and the resulting product performance. The hot isostatic pressing of cemented carbide can eliminate the pores in the alloy and the drilling pool after sintering, and restrain the growth of WC grain. The Kennametal Inc installed the first heating chamber for 277mm * 1270mm in 1967. The temperature is up to 1500oC and the pressure can reach140MPa's hot isostatic pressing machine has taken the lead in successfully applying the technology of hot isostatic pressing to the production of cemented carbide. Since then, hot isostatic pressing technology has developed rapidly in foreign countries (especially in the United States).

- Q:Classification of Cemented Carbides

- 1 tungsten cobalt carbide2, tungsten, titanium and cobalt carbide3, tungsten, titanium, tantalum (niobium) carbide

- Q:What does carbide K15-K20 refer to?

- The smaller the value, the harder the hardness of the table is and the less resistant it is to the impact;

- Q:What are the standard units of measurement for carbide inserts?

- Manufacturers usually use KG, which is used inside the shop

- Q:What is the base material of carbide saw blade?

- You can go to Zhuzhou tungsten alloy technology forum to see, detailed description of the carbide saw blade related knowledge, you can go to a lot of professionals with whom to communicate inside.

- Q:What are the features of cemented carbide YG8 knives?

- Density: 14.6-14.8; hardness HRA:90.5; flexural strength, Mpa2300High bending strength, shock resistance and vibration resistance is better than YG6. It is suitable for low speed rough machining of cast iron, non-ferrous metals and their alloys, and non-metallic materials

- Q:Make cutting dosage

- But modern machining, has no strict distinction between the T and G class, but in different types of processed materials and processing conditions, different ways such as the use of different materials, and with appropriate coating, to reduce the cost requirements.Cutting parameters need to be selected according to different cutting occasions and different materials to be machined.

- Q:What does American standard cemented carbide grain size C mean?

- Therefore, their composition can change in a certain range (such as the composition of titanium carbide in TiC0.5 ~ TiC changes), chemical formula does not conform to the rules of valence. When the dissolved carbon content exceeds a certain limit (such as titanium carbide in Ti: C=1: 1), the lattice type will be changed, the original metal lattice metal lattice into another form, then the interstitial solid solution called interstitial compounds. Metal carbides, especially B, B, IV V VI B metal carbide melting point is above 3273K, the TAC hafnium carbide, respectively 4160K and 4150K, is the highest point currently know material. Most of the carbide hardness large, their microhardness is higher than 1800kg mm2 (micro hardness is hardness says one way for hard alloy and hard compound, microhardness 1800kg mm2 is equivalent to a diamond a Mohs hardness of 9). Many carbides are difficult to break down at high temperatures, and their antioxidant power is stronger than their constituent metals. Titanium carbide has the best thermal stability in all carbides, and is a very important metal type carbide. However, in an oxidizing atmosphere, all carbides are readily oxidized at high temperatures, which can be said to be a major weakness of carbides.

- Q:Where does Tianjin sell yt30 carbide tool?

- Now there are the same, express, everything is not afraid. I am the agent of Zigong the Great Wall brand cemented carbide, quality assurance, definitely authentic.

- Q:Welding hard alloy cutter, hard alloy cutter, high speed steel, ceramic knife head head are what are the advantages and shortcomings?

- Advantages of carbide drills:1. can be used for drilling more complex materials, you can choose a higher cutting speed.2., selection of alloy drill special high-performance alloy blade, effectively reduce the avalanche knife, and maintain good wear resistance.3. multi layer geometry cutting end blade improves discharge performance and maintains smaller cutting resistance.4., in addition to the commonly used right angle stem, there are a variety of handle type, suitable for a variety of drilling machines, drilling machine matching.Disadvantages of carbide drills:The advantages of carbide drill can drill more hard material, the disadvantage is to be good grinding, grinding is not good, easy to break the edge, two main cutting edge height and angle equivalent, it is best to use the grinding machine.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LC LOW CARBON FERRO CHROME FECR ALLOYS MANUFACTURER SUPPLY

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords