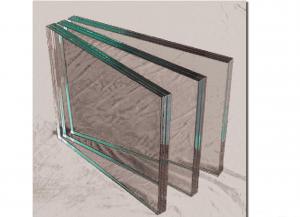

Laminated Glass-2

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated Glass is made of high quality float glass, coated glass of various colors, Low-E glass, tempered glass, thermo-strengthening glass and bent/tempered glass. It is a product integrated with two or more glass sheets and one or more layers of organic polymers like PVB, EVA, SGP, etc. It is processed by the tablet machine under high pressure and high temperature, making it unite into one lastingly.

Features:

1. Safety glass

2. Fine light control and heat insulation when using coated glass

3. Sound insulation and noise reduction

4. Good structural feature

5. In order to guarantee the quality of laminated glass, the PVB films are imported from Dupont of the USA or Sekisui of Japan.

6. The colors of the films include clear, milk, blue, dark grey, light green, bronze, etc.

Specifications:

Thickness of Glass: 3mm; 4mm; 5mm; 6mm; 8mm; 10mm; 12mm

Thickness of PVB film: 0.38-3.04mm

Size:

300*300mm

3000*8000mm

customized size

Applications:

Laminated Glass is applied in curtain walls, hotels, banks, airports, sunshades, lighting roofs, windows and gates, sprung roofs, indoor glass partitions, glass furniture, show windows, bars, jewelry shops, elevators and so on.

- Q:The practice of acid corrosion in tank

- The performance of loading and canning is excellent. The heavy duty coating can keep good storage stability, and the rheological and shearing properties of the coating are constant, and the temperature change is less affected. No delamination after opening, no precipitation, easy to disperse and stir.

- Q:What are the construction principles and raw materials of tempered glass?

- Tempered glass, also called toughened glass, is a kind of prestressed glass. It uses physical or chemical methods to form a compressive stress layer on the surface of glass. The glass itself has a higher compressive strength and will not cause damage. When the glass is subjected to external force, the pressure layer may be part of the tensile stress offset, avoid broken glass, although tempered glass is in large internal stress state, but the glass no internal defects, without causing damage, so as to achieve the purpose of improving the strength of glass. It is well known that microcracks on the surface of materials are the main causes of material rupture. Because the microcrack will expand gradually under the action of tension, and finally crack along the crack. And because of the large compressive stress on the surface of the glass, the microcracks on the glass surface become more fine and even heal under the action of extrusion".

- Q:Method for cutting thick glass

- Some glass processing before processing, to the original piece of glass polishing, cutting, edge grinding, drilling, washing and drying process, such as tempered glass, laminated glass etc.; there are some glass processing technology, processing after washing and drying, and then according to the use requirements of cutting, grinding, grinding and polishing drilling and washing as final products, such as glass mirror; in addition to the art glass, such as painting, printmaking, relief, need specific processing technology, these are for cold working glass. The cold processing of glass is to process glass products into the required process by means of a series of processing methods at normal temperature.

- Q:What is resin glass fiber reinforced plastic?

- Raw materials: glass fiber / or its products + resin + (filler) + other additives;Process: hand / pull / winding / molding / injection molding etc..Resin is only a raw material for the production of glass fiber reinforced plastic! That's not what you call it.

- Q:Is glass fiber reinforced plastic board fireproof partition board?

- FRP sheet is not fireproof partition board.

- Q:Why are most of the chemical instruments made from glass?

- Of course, the glass is colorless and transparent is also very important, the front of some people said that the glass is cheap, I would like to deny, in fact, this glass is not often in general glass, high temperature, the cost is much higher than that

- Q:Who has information about power plants chimneys, water glass, acid resistant concrete?

- The characteristics of water glass concrete acid: water glass acid resistant concrete with water glass as binder, sodium fluorosilicate as hardening agent, adding acid powder and acid aggregate or other additives according to a certain proportion. Features: the acid and good heat resistance, it can resist all kinds of strong oxidizing acid (such as sulfuric acid, hydrochloric acid, nitric acid) and most corrosive gases (oxygen, sulfur dioxide) erosion at high temperature (1000 DEG C) still has good acid resistance, mechanical strength and high. But this material is not resistant to hydrofluoric acid, more than 300 degrees of hot phosphoric acid and higher fatty acids or oleic acid erosion. Is a commonly used anti-corrosion material, it has a wide range of materials, acid resistance good, low cost advantages. Its disadvantages are no alkali resistance, poor impermeability and water resistance, complex construction, long maintenance period.

- Q:What chemicals can be made from glass, paper, detergents, etc?

- Common is soda ash. Glass has silica, soda ash, sodium carbonate, high temperature heating. Paper generally use cellulose, bleaching powder. Detergent (mainly soap), usually sodium stearate

- Q:What are the main materials for making glass?

- Silica is the main raw material made of silica on the earth reserves is great. Silica is the main raw material for the main raw material is made of glass stones. The silicon content of different rocks are different. In our life of these materials is the most common.

- Q:Glass raw materials processing equipment, glass raw materials crushing equipment prices generally sell how much?

- Glass raw material processing technology and equipment, advanced at present, glass raw material (quartz sandstone, feldspar, silica) processing generally adopts the following process: A, wet rodmill; B, by the back breaking or jaw crusher and roll composed of multi-stage crushing and screening line.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 2009 |

| Annual Output Value | Below US$1 Million |

| Main Markets | West Europe; Southeast Asia; Africa |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 71% - 80% |

| No.of Employees in Trade Department | 20 |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 10000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Laminated Glass-2

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords