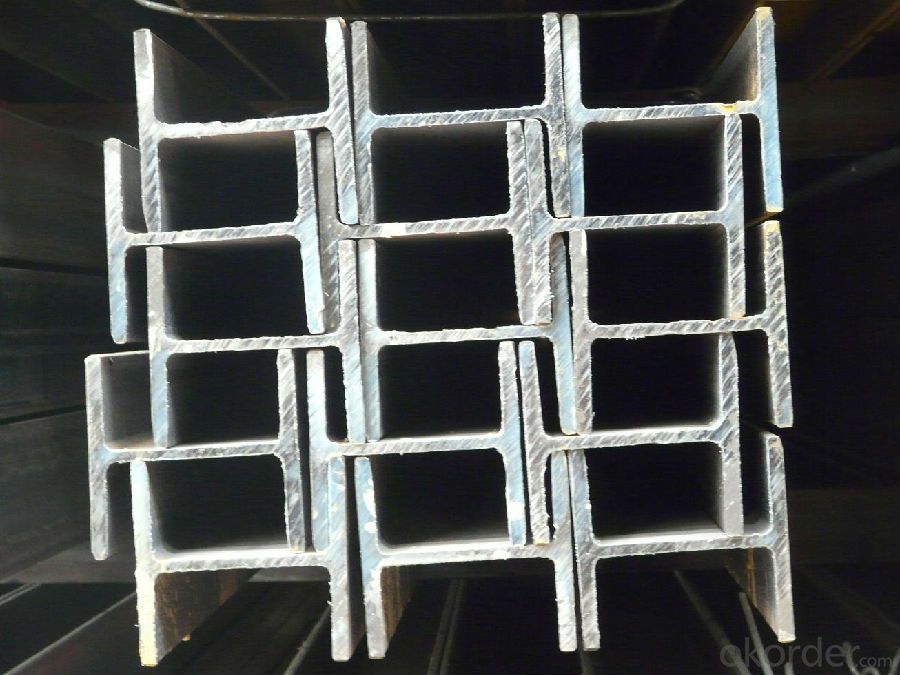

I Beam Prime Hot Rolled IPE IPEAA EN 10025 Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||

a*t | ||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do you package the angle steel when shipping?

A2: All goods are packed in bundles with steel strips and shipped by container or break bulk.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q:Own attic, choose I-beam or channel?

- Channel steel: used for construction and mechanical use of carbon structural steel, is a complex cross-section of steel.Channel characteristics:Channel steel can change the structure of the building, and save construction materials.If the channel is constructed, it will be quick enough to be ready for use without waiting.Inadequate: it is an attic made of channel steel. When people move on it, there will be a certain shake. The smaller the channel gauge, the greater the sloshing. The larger the channel gauge, the smaller the shaking

- Q:Can steel I-beams be used in marine environments?

- Yes, steel I-beams can be used in marine environments. Steel is a popular material choice for marine applications due to its high strength, durability, and resistance to corrosion. However, it is important to consider certain factors when using steel I-beams in marine environments. One of the main concerns in marine environments is the risk of corrosion. Steel I-beams are typically coated with protective layers such as paint or galvanization to prevent corrosion. These protective coatings create a barrier between the steel and the corrosive elements present in the marine environment, such as saltwater and humidity. Additionally, the design of steel I-beams for marine applications should take into account factors such as wave forces, water pressure, and potential impacts from floating objects. Reinforcements and additional bracing may be required to ensure the structural integrity and stability of the I-beams in these challenging conditions. Regular inspection and maintenance are also crucial to ensure the longevity of steel I-beams in marine environments. Inspections should include checking for any signs of corrosion, damage to the protective coatings, or structural issues. Prompt repairs or replacements should be carried out if any issues are identified. Overall, steel I-beams can be effectively used in marine environments when the appropriate protective coatings, design considerations, and maintenance practices are implemented.

- Q:Can steel I-beams be recycled?

- Yes, steel I-beams can be recycled. Steel is a highly recyclable material, and I-beams are commonly recycled to produce new steel products. Recycling steel helps conserve natural resources, reduce energy consumption, and minimize waste.

- Q:What's the difference between I-beam and H steel? What's the weight of the same size?

- H type steel with flange width, and narrow distinction, respectively represented by HW, HM, HN and web and flange size, species diversity, such as HM500x300x11x15, on behalf of waist high 500mm, 11mm thickness, flange width 300mm, thickness 18mm, this is in fact the theory of value with the actual deviation will beIt's impossible to have the same sizes of I-beam and H.

- Q:Can steel I-beams be used in healthcare or hospital renovation projects?

- Yes, steel I-beams can be used in healthcare or hospital renovation projects. Steel I-beams have several advantages that make them suitable for such projects. Firstly, steel is a strong and durable material that can withstand heavy loads, making it ideal for supporting the weight of floors, walls, and ceilings in healthcare facilities. Secondly, steel I-beams are fire-resistant, which is crucial in hospitals where safety is of utmost importance. Additionally, steel is resistant to pests, such as termites, which can be a concern in older buildings. Moreover, steel I-beams can be easily fabricated and customized to fit specific project requirements, allowing for flexibility in design. Lastly, steel is a sustainable and environmentally friendly material, as it can be recycled and reused, reducing the project's carbon footprint. Overall, steel I-beams provide a reliable and efficient solution for healthcare or hospital renovation projects.

- Q:What does the beam size "H500*250*8*10*10" mean?

- Height H * width B * web thickness * wing plate thickness, and finally that 10 should be superfluous, it is produced by professional manufacturers, digital means:Height * width * plate thickness * vertical plate thickness

- Q:Can steel I-beams be used for pedestrian bridges over rivers or canals?

- Pedestrian bridges over rivers or canals can indeed utilize steel I-beams. The utilization of steel I-beams is widespread in the construction of bridges due to their exceptional strength, durability, and versatility. They possess the capability to span great distances and endure heavy loads, rendering them ideal for pedestrian bridges that necessitate safe passage for foot traffic. Furthermore, steel I-beams exhibit resistance against the damaging effects of water and adverse weather conditions, a critical factor for bridges constructed above rivers or canals. These beams can be custom designed and fabricated to fulfill the precise requirements of the bridge, ensuring its ability to withstand the necessary loads and provide pedestrians with a secure crossing.

- Q:Can steel I-beams be used in coastal areas prone to saltwater exposure?

- Yes, steel I-beams can be used in coastal areas prone to saltwater exposure. However, it is important to consider the potential effects of saltwater on the steel beams and take necessary measures to prevent corrosion. Saltwater contains high levels of salt, which can accelerate the corrosion process of steel. To mitigate this risk, several strategies can be employed. Firstly, using corrosion-resistant coatings on the steel beams is crucial. These coatings, such as zinc or epoxy coatings, act as a barrier between the steel and the saltwater, preventing direct contact and reducing the risk of corrosion. Regular inspections and maintenance of the coatings are necessary to ensure their effectiveness over time. Secondly, proper ventilation and drainage systems should be implemented to minimize the accumulation of saltwater on the steel beams. This helps to prevent prolonged exposure to saltwater, reducing the risk of corrosion. Thirdly, selecting the appropriate type of steel for the I-beams is important. Stainless steel or galvanized steel, which have higher resistance to corrosion, are often recommended for structures in coastal areas. Finally, regular maintenance and monitoring of the steel beams are essential to identify and address any signs of corrosion early on. This may involve routine inspections, cleaning, and applying additional protective coatings as needed. By implementing these measures, steel I-beams can be used effectively in coastal areas prone to saltwater exposure, providing structural integrity and durability over time.

- Q:What are the independent foundations of the square column and the I-beam column?

- The steel column baseboard size is known, the independent foundation short column size request is bigger than the column baseboard, each side 100, and is bigger than the anchor bolt each side 5D and 150.

- Q:How do steel I-beams perform in terms of fire safety?

- Steel I-beams are highly esteemed for their exceptional fire safety performance. The inherent characteristics of steel make I-beams highly resilient to fire, making them an ideal option for structural applications that prioritize fire safety. To begin with, steel possesses a high melting point, typically reaching around 2,500 degrees Fahrenheit (1,370 degrees Celsius). Consequently, during a fire, steel I-beams can endure high temperatures for an extended period without compromising their structural integrity. Unlike materials like timber or concrete, which can weaken or even collapse under extreme heat, steel maintains its strength and load-bearing capacity. Moreover, steel I-beams exhibit a low flammability, meaning they are not easily ignited and do not contribute to the spread of flames. Steel is non-combustible and does not emit toxic gases or smoke when exposed to fire. This characteristic plays a crucial role in impeding the rapid propagation of fire in a building, allowing occupants more time to evacuate safely. Additionally, steel I-beams possess a high thermal conductivity, enabling them to rapidly dissipate heat. This property helps prevent the formation of localized areas of intense heat, thus reducing the risk of structural failure. It also facilitates the swift cooling of the steel after the fire has been extinguished, minimizing the potential for post-fire damage. Nevertheless, it is important to acknowledge that despite the excellent fire-resistant properties of steel I-beams, prolonged exposure to high temperatures can still affect them. Over time, excessive heat can lead to a loss of strength and structural integrity in the steel. Therefore, it is necessary to employ fire protection measures such as fire-resistant coatings or fireproof insulation to further enhance the fire safety performance of steel I-beams. To conclude, steel I-beams demonstrate remarkable fire safety performance. Their high melting point, low flammability, and efficient heat dissipation make them a dependable choice for structural applications that prioritize fire safety. However, it is crucial to implement additional fire protection measures to ensure optimal fire resistance and comply with local building codes and regulations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

I Beam Prime Hot Rolled IPE IPEAA EN 10025 Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords