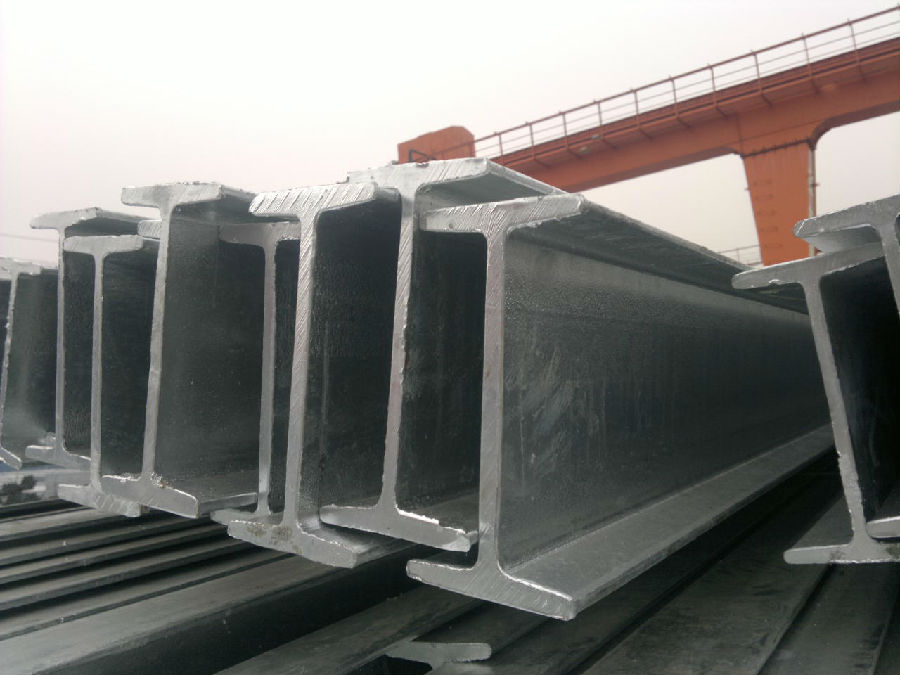

BS Standard Structural Steel I-Beam

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 200000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality BS Standard Structural Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

BS Standard Structural Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: SS400, ST37-2, A36, S235 JRG1, Q235, Q345

Standard: BS, JIS, ASTM, DIN, EN, GB/T 700-1988

Certificates: ISO, SGS, BV, CIQ

Dimensions:

Chinese Standard: 100*68*4.5mm, 630*180*17mm

European Standard: 80*46*3.8mm, 600*220*12mm

Length: 6m, 9m, 12m

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q:Can steel I-beams be used in warehouse construction?

- Yes, steel I-beams can be used in warehouse construction. In fact, they are commonly used due to their strength and durability. Steel I-beams provide excellent load-bearing capacity, allowing for the construction of large open spaces without the need for excessive columns or supports. This makes them ideal for warehouse construction, where maximizing floor space is often a priority. Additionally, steel I-beams can be easily fabricated and customized to suit specific design requirements, making them versatile and adaptable for various warehouse layouts.

- Q:Can steel I-beams be used in agricultural buildings?

- Yes, steel I-beams can be used in agricultural buildings. Steel I-beams are a popular choice for structural support in a variety of buildings, including agricultural structures. They offer several advantages such as high strength, durability, and resistance to pests, fire, and rot. Steel I-beams can provide the necessary load-bearing capacity to support the weight of equipment, livestock, and storage materials commonly found in agricultural buildings. Moreover, their versatility allows for flexible design options, making it easier to customize the building layout to suit specific agricultural needs. Overall, steel I-beams are a reliable and practical choice for constructing agricultural buildings.

- Q:How do you protect steel I-beams from corrosion?

- One of the most effective ways to protect steel I-beams from corrosion is by applying a protective coating. There are several types of coatings available, such as paint, epoxy, or galvanization, each with its own benefits and suitability for different environments. Paint coatings provide a barrier between the steel and the surrounding environment, preventing moisture and oxygen from coming into contact with the metal surface. It is crucial to use a high-quality paint specifically designed for corrosion protection, ensuring proper surface preparation and application techniques. Regular maintenance and touch-ups may be required as paint coatings can deteriorate over time. Epoxy coatings offer enhanced corrosion resistance and durability compared to paint. These coatings are typically applied in multiple layers and provide a thicker and more robust protective barrier. Epoxy coatings are commonly used in high-corrosion environments, such as offshore structures or chemical plants. Galvanization is another effective method to protect steel I-beams from corrosion. It involves coating the steel with a layer of zinc, which acts as a sacrificial anode. Zinc corrodes preferentially, sacrificing itself to protect the steel. Hot-dip galvanization is the most common method used, where the steel is immersed in a bath of molten zinc. This process creates a thick, durable, and long-lasting protective coating. In addition to protective coatings, proper maintenance and regular inspections are essential. Any signs of damage or corrosion should be addressed promptly to prevent further deterioration. Routine cleaning, removing debris, and ensuring adequate drainage around the I-beams can also help prevent corrosion. It is important to consider the specific environment and conditions in which the steel I-beams will be exposed. Consulting with corrosion specialists or engineers can provide valuable insights and recommendations on the most suitable corrosion protection methods for the given application.

- Q:What are the different types of steel coatings used for I-beams?

- I-beams commonly utilize various types of steel coatings, serving to protect against corrosion and enhance durability and longevity. Hot-dip galvanizing is one frequently employed method, where beams are immersed in a bath of molten zinc, creating a protective layer on the steel's surface. This technique offers exceptional corrosion resistance, making it ideal for outdoor or moist environments. Another coating option is epoxy coating, wherein a layer of epoxy paint is applied to the beams. These coatings establish a robust barrier against corrosion and can be customized to meet specific requirements, such as high chemical or fire resistance. Zinc-rich paint coatings are also widely used for I-beams, featuring a high concentration of zinc particles that offer cathodic protection to the steel. These zinc particles act as sacrificial anodes, corroding in place of the steel, effectively extending its lifespan. Additionally, thermal spray coatings like metallizing or flame spraying involve applying a layer of molten metal to the beams' surface. These coatings provide exceptional corrosion protection and can be tailored to meet specific performance needs. Ultimately, the selection of a steel coating for I-beams relies on factors such as the desired level of corrosion resistance, environmental conditions, and specific performance requirements. Consulting a professional coating specialist is crucial in determining the most suitable coating for a particular application.

- Q:Can steel I-beams be used in multi-story buildings?

- Indeed, multi-story buildings often make use of steel I-beams. Renowned for their remarkable strength and durability, steel I-beams are well-suited for bearing heavy loads across expansive distances. Their utility is frequently observed in the construction of structural frameworks, where they serve as columns and beams, providing the essential support and stability for multi-story buildings. Moreover, steel I-beams possess a relatively low weight when compared to alternative construction materials, enabling swifter building processes and decreased expenses. Ultimately, the versatility and robustness of steel I-beams render them an exceedingly favored option in multi-story building construction.

- Q:Can steel I-beams be used for roof trusses?

- Indeed, roof trusses can utilize steel I-beams. Owing to their robustness and longevity, steel I-beams are extensively employed in the construction industry. In the context of roof trusses, they offer exceptional support and stability to the roof framework. Unlike alternative materials like wood, steel I-beams have the ability to endure substantial loads and span greater distances. Moreover, steel I-beams are impervious to decay, pests, and fire, rendering them a trustworthy option for roof trusses. Nevertheless, it is crucial to guarantee that the design and installation of steel I-beams for roof trusses comply with local building codes and regulations to ensure adequate structural integrity and safety.

- Q:What is the most cost-effective size for a steel I-beam?

- The most cost-effective size for a steel I-beam depends on several factors, including the specific application, load requirements, and budget constraints. It is essential to consider the structural design requirements and the expected loads that the beam will need to support. To determine the most cost-effective size for a steel I-beam, it is crucial to consult with a structural engineer or a professional who specializes in steel construction. They can analyze the project's specifications and provide calculations and recommendations based on industry standards and guidelines. Factors that influence the selection of an appropriate size include the span length, the weight or load to be supported, the desired deflection limits, and the available budget. By considering these factors, the engineer can determine the required moment of inertia and section modulus for the beam. Once the required moment of inertia and section modulus are established, the engineer can analyze various standard sizes of steel I-beams available in the market. They will consider the beam's dimensions, weight per foot, and the material cost to determine the most cost-effective size. It is important to note that cost-effectiveness is not solely determined by the upfront material cost. Other factors such as installation, fabrication, transportation, and long-term maintenance costs should also be considered. Additionally, the engineer will evaluate the safety and structural integrity of the chosen beam size to ensure it can adequately support the anticipated loads and meet all applicable building codes and regulations. Ultimately, the most cost-effective size for a steel I-beam will be the one that satisfies all the project requirements while minimizing material and installation costs. Working with a qualified professional is crucial in making the best decision for the specific project.

- Q:How do you calculate the torsional deflection of a steel I-beam?

- To calculate the torsional deflection of a steel I-beam, you need to consider various factors and apply relevant formulas. Here is a step-by-step guide to calculate the torsional deflection: 1. Gather the necessary information: Start by collecting the required data, including the dimensions of the I-beam, such as its height (h), width of the flanges (b1 and b2), thickness of the flanges (t1 and t2), and the length of the beam (L). 2. Determine the material properties: Identify the properties of the steel being used, especially the modulus of rigidity (G) or shear modulus. This value represents the material's resistance to shear deformation and is necessary for the calculations. 3. Calculate the cross-sectional area: Determine the cross-sectional area of the I-beam by subtracting the area of two rectangles (flanges) from the area of one rectangle (web). The area of the web can be calculated as A = h * (b1 - t1 - t2) + b2 * t2. 4. Determine the polar moment of inertia: The polar moment of inertia (J) represents a beam's resistance to torsional deformation. It can be calculated using various formulas depending on the shape of the cross-section. For an I-beam, the formula is J = (b1 * t1^3 + b2 * t2^3) / 3. 5. Calculate the maximum shear stress: The maximum shear stress (τ) caused by torsional loading can be calculated using the formula τ = T * r / J, where T is the applied torque and r is the distance from the center of the beam to the outermost point on the cross-section. 6. Determine the torsional deflection: The torsional deflection (θ) can be calculated using the formula θ = T * L / (G * J), where T is the applied torque, L is the length of the beam, G is the shear modulus, and J is the polar moment of inertia. By following these steps and plugging in the appropriate values, you can calculate the torsional deflection of a steel I-beam. It is important to note that these calculations provide an approximation and should be verified by a professional engineer to ensure accuracy and safety.

- Q:How do steel I-beams contribute to the overall energy efficiency of a building?

- Steel I-beams contribute to the overall energy efficiency of a building by providing structural support and reducing the need for excessive material usage. Their strength and durability allow for the construction of larger spans, enabling open floor plans and maximizing natural light, which in turn reduces the reliance on artificial lighting and enhances energy efficiency. Additionally, steel I-beams have excellent thermal conductivity, facilitating efficient heating and cooling distribution throughout the building, thus reducing energy consumption and promoting sustainability.

- Q:How do you reinforce a steel I-beam?

- To reinforce a steel I-beam, several methods can be employed depending on the specific requirements and circumstances. Here are a few common ways to reinforce a steel I-beam: 1. Welding additional steel plates: One method is to weld additional steel plates onto the flanges or web of the I-beam. These plates can be strategically placed to increase the beam's strength and load-carrying capacity. The size and thickness of the plates will depend on the required reinforcement. 2. Adding steel sections: Another approach is to add additional steel sections to the existing I-beam. This can be done by welding or bolting them together to form a composite beam. By combining multiple beams, the overall strength and stiffness of the structure can be enhanced. 3. External bracing: External bracing can be used to reinforce an I-beam. This involves attaching braces or cross-members to the beam to provide additional support and prevent buckling or twisting. Bracing can be made from steel, concrete, or other materials, and is typically designed based on the specific load and structural requirements. 4. Carbon fiber reinforcement: Carbon fiber materials can be used to reinforce steel I-beams. Carbon fiber sheets or strips can be bonded to the beam's surface using epoxy resin. This technique adds strength and stiffness to the beam, while also providing resistance against corrosion and maintaining a lightweight structure. 5. Post-tensioning: Post-tensioning is a technique where high-strength steel tendons or cables are installed within the beam and then tensioned. This process applies compressive forces to the beam, increasing its load-carrying capacity and reducing deflection. Post-tensioning is commonly used in larger structures and requires specialized expertise. It is important to note that reinforcing a steel I-beam should be done by a qualified structural engineer or professional with knowledge of the specific requirements and load conditions. They can assess the structural needs, calculate the required reinforcement, and ensure that the modifications comply with relevant building codes and standards.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BS Standard Structural Steel I-Beam

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 200000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords