Hot Rolled Square Steel Bars 6mm-150mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

There are two types of Square Bar, one is hot rolled square bar and other one is cold drawn square bar. Our principal products is hot rolled square bar. We dedicate to products with material Q195 and Q235. We offer products with high quality and low price.

Specifications of Hot-rolled Square Steel Bar:

-Standard: GB,

-Grade: Q195/Q235 or equivalent.

-Chemical Composition:

Standard | Grade | Element (%) | ||||

C | Mn | S | P | Si | ||

GB | Q195 | 0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 |

GB | Q235B | 0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 |

-Mechanical Properties:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

Measures of Hot-rolled Square Steel Bar (Big measures):

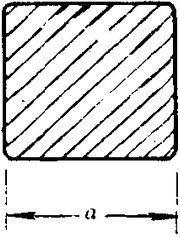

(Section of Hot-rolled Square Steel Bar)

-Length of a side and Theoretical weight of Square Bar (Big measures).

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

53 | 22.05 | 80 | 50.24 |

56 | 24.61 | 85 | 56.72 |

60 | 28.26 | 90 | 63.59 |

63 | 31.16 | 95 | 70.85 |

70 | 38.49 | 100 | 78.50 |

75 | 44.16 |

|

|

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: a(length of a side) * a * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

Usage/Applications of Hot-rolled Square Steel Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Row material for steel pipes.

Packaging & Delivery of Hot-rolled Square Steel Bar:

-Packing Detail:

1, The products can be packed in bundles by steel wires.

2, The weight of each bundle no exceed normally 3 tons.

-Marks: We make tag marks and color marks for each bundle. The tag marks with white background and red company log will be tied up to each bundle. The information is usually including basic information of company and products like product name, specification, etc...and other information required by customers. As for color marks, we will paint both ends of each bundles to make sure that it will be more convenient for customers to distinguish theme from other products.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

-The payment terms will be written in contraction detailedly.

Photos of Hot-rolled Square Steel Bar:

We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

- Q:Can a steel square be used for checking the squareness of a workbench top?

- Yes, a steel square can be used for checking the squareness of a workbench top.

- Q:How do you use a steel square to measure the width of a door jamb?

- To use a steel square to measure the width of a door jamb, follow these steps: 1. Ensure you have a steel square that has a long blade and a shorter tongue perpendicular to each other. This is often called a framing square or carpenter's square. 2. Start by holding the steel square against the inside edge of the door jamb, with the long blade touching the floor and the tongue facing towards the door opening. 3. Slide the square until the long blade is flush against one side of the door jamb. Make sure the square is held firmly and remains level. 4. Look at the measurement markings on the long blade of the square. The numbers on the blade represent inches or centimeters. Identify the mark that aligns with the opposite side of the door jamb. This will give you the width measurement of the door jamb. 5. Take note of the measurement and repeat the process on the other side of the door jamb to ensure accuracy. If the door jamb is not perfectly square, take multiple measurements at different points along the jamb to get an average width. By following these steps, you can effectively use a steel square to measure the width of a door jamb. It is important to have a steady hand and ensure the square remains level for accurate measurements.

- Q:How do you use a steel square to determine the angle of a chamfer cut?

- To determine the angle of a chamfer cut using a steel square, follow these steps: 1. Place the steel square against the edge of the material where the chamfer cut will be made. 2. Align one leg of the square with the flat surface of the material and make sure it is firmly against the edge. 3. Observe the other leg of the square as it extends beyond the material's edge. 4. Read the angle measurement on the scale of the steel square where the extended leg intersects. 5. This angle measurement will give you the precise angle of the chamfer cut, which can be replicated for accurate results.

- Q:How do you use a steel square to determine the angle of a compound routing template cut?

- To use a steel square to determine the angle of a compound routing template cut, you would first align the square's long edge with the desired angle on the template. Then, by adjusting the square's position, you can find the exact angle measurement by referring to the square's degree scale.

- Q:What are the different types of steel used in manufacturing steel squares?

- There are several different types of steel used in manufacturing steel squares, each with its own unique properties and characteristics. 1. Carbon Steel: This is the most common type of steel used in manufacturing steel squares. It is a versatile material that offers a good balance of strength and affordability. Carbon steel squares are durable and can withstand heavy use. 2. Stainless Steel: This type of steel is known for its corrosion resistance and high strength. Stainless steel squares are often used in industries where hygiene and cleanliness are important, such as food processing or medical equipment manufacturing. 3. Alloy Steel: Alloy steel squares are made by adding other elements to carbon steel, such as chromium, molybdenum, or nickel. This results in improved strength, toughness, and wear resistance. Alloy steel squares are commonly used in applications that require high strength and durability, such as construction or automotive manufacturing. 4. Tool Steel: Tool steel squares are specifically designed for use in cutting, shaping, or forming other materials. They have excellent hardness, wear resistance, and heat resistance. Tool steel squares are commonly used in tool and die making, machining, or metalworking industries. 5. High-Speed Steel: High-speed steel squares are a type of tool steel that has been specially designed to withstand high temperatures and cutting speeds. They are commonly used in applications that involve high-speed machining or cutting, such as drilling or milling. Overall, the choice of steel for manufacturing steel squares depends on the specific application and requirements. Each type of steel offers unique properties that can enhance the performance and durability of the steel squares.

- Q:How do you use a steel square to mark a line parallel to a board edge?

- To use a steel square to mark a line parallel to a board edge, follow these steps: 1. Place the steel square on the board edge with one of its edges aligned with the edge of the board. 2. Hold the steel square firmly in place, ensuring it doesn't shift or move. 3. Take a pencil or marking tool and place it against the other edge of the steel square. 4. While keeping the pencil in contact with the edge of the steel square, carefully slide it along the length of the square. 5. As you slide the pencil, it will leave a mark on the board, parallel to the edge of the board. 6. Continue sliding the pencil until you have marked the desired length or distance along the board. 7. Once you have marked the line, double-check its parallelism by measuring the same distance at different points along the line. Use a tape measure or ruler to ensure accuracy. By using a steel square and following these steps, you can easily mark a line parallel to a board edge. This technique is particularly useful in carpentry and woodworking projects where precision is essential.

- Q:How is a steel square different from a carpenter's square?

- Both construction and woodworking employ measuring tools such as steel squares and carpenter's squares, but they possess distinct characteristics. To begin with, the manner in which these squares are constructed and the materials used diverge. The steel square, as its name suggests, is fashioned entirely from steel, rendering it heavier and more resilient. Conversely, a carpenter's square typically consists of wood, supplemented with a metal edge or lip to guarantee precision. Regarding design, a steel square boasts a lengthier body with a broader base and an L-shaped structure incorporating two arms that intersect at a right angle. One arm serves as a measuring device, while the shorter arm aids in achieving accurate cuts or angles. Conversely, a carpenter's square, also referred to as a try square, possesses a shorter body with a right-angled shape, rendering it suitable for assessing corner precision and marking 90-degree angles. Another distinction lies in functionality. The steel square exhibits greater versatility, facilitating measurement, angle marking, and cut line layout. It often includes supplementary features like a level, protractor, and scribe, making it an exhaustive tool for diverse construction endeavors. Conversely, a carpenter's square principally serves the purpose of verifying right angles and ensuring squareness in woodworking projects. Carpenters and cabinetmakers commonly employ it for layout tasks, aligning joinery, and verifying the accuracy of cuts and joints. In summary, while both steel squares and carpenter's squares fulfill analogous objectives, their disparities reside in their construction, design, and functionality. Steel squares excel in durability and versatility, whereas carpenter's squares represent simpler tools primarily employed for assessing right angles and guaranteeing precision in woodworking projects.

- Q:How do you use a steel square to determine angles for picture frames?

- In order to determine angles for picture frames using a steel square, it is necessary to follow a few simple steps. To begin, position the steel square on one corner of the frame, ensuring that the long edge of the square is aligned with the frame's edge. Securely hold the square in place, ensuring it remains stationary while taking measurements. Examine the two arms of the steel square. One arm is shorter, typically measuring around 6 inches, while the other arm is longer, usually around 12 inches. The shorter arm is referred to as the tongue, whereas the longer arm is known as the blade. Next, inspect the markings on the blade of the square. These markings represent various angles, typically ranging from 0 to 90 degrees. Align the blade of the square with the frame's side and observe which angle marking coincides with the edge of the frame. Take note of the angle indicated by the matching marking, as this will represent the angle of the frame corner. Repeat this procedure for each corner of the frame, ensuring proper alignment of the square and accurate recording of each corner's angle. By utilizing a steel square in this manner, it is possible to accurately determine the angles required for crafting picture frames with flawless corners.

- Q:How do you use a steel square for marking window and door trim angles?

- To use a steel square for marking window and door trim angles, first, place the square against the edge of the trim. Then, adjust the square until one side aligns with the trim edge and the other side is perpendicular to it. Next, use a pencil to mark along the edge of the square, creating a straight line that indicates the desired trim angle. Repeat this process for each corner or angle that needs to be marked.

- Q:Can a steel square be used for checking the alignment of tiles?

- No, a steel square is not typically used for checking the alignment of tiles. A tile spacer or a laser level is commonly used for this purpose to ensure accurate and level tile placement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Square Steel Bars 6mm-150mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords