Hot-rolled Square Steel Bar With Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Square Steel Bar:

-The Square Steel is hot rolled,

-Standard: GB,

-Grade: Q235 or equivalent.

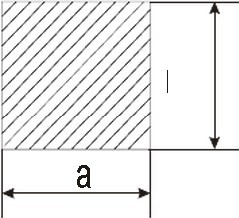

(The section of Square Steel)

Some details of Square Steel Bar:

-List 1. Chemical Composition.

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

-List 2. Physical Properties

Grade | Q235B | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | 235 | 225 | 215 | 205 | |

Tensile Strength | 375~500 | ||||

Elongation δ5% | 26 | 25 | 24 | 23 | |

-List 3.The length of a side and the theoretical weight of Square Steel.

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 70 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-List 4. The allowed tolerance of Square Steel:

Length of a side(mm) | Allowed Tolerance | ||

Group1 | Group2 | Group3 | |

5.5~7 | ±0.20 | ±0.30 | ±0.40 |

7~20 | ±0.25 | ±0.35 | ±0.40 |

20~30 | ±0.30 | ±0.40 | ±0.50 |

30~50 | ±0.40 | ±0.50 | ±0.60 |

60~80 | ±0.60 | ±0.70 | ±0.80 |

80~110 | ±0.90 | ±1.0 | ±1.1 |

110~150 | ±1.2 | ±1.3 | ±1.1 |

150~190 | ―― | ―― | ±2.0 |

190~250 | ―― | ―― | ±2.5 |

Usage/Applications of Square Steel Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Raw material for square tubes.

Packaging & Delivery of Square Steel Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation & Marking:

-Transportation:

1, The products can be delivered by bulk vessel or by container.

2, The maximum quantity of loading of container is 25 tons.

3, The products usually are transported to the nearest port from the production place.

-Marks:

1, Color mark: there will be color marking on both ends of the bundles for the cargo delivered by bulk vessel. That makes is easily to distinguish at the destination port.

2, Tag mark: the tag marks will be tied up to each bundle. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications and other information requested by customers.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

Photos of Square Steel Bar:

-Products details(Tag Marks):

-Square Steel Bar during the transportation:

- Q:Can a steel square be used for window and door framing?

- Window and door framing can indeed utilize a steel square. These squares, which are also referred to as framing squares or carpenter squares, serve as versatile tools that are commonly employed in construction and carpentry. They possess the capacity to provide accurate and square measurements and angles, thereby rendering them suitable for a variety of framing tasks, including window and door installation. By virtue of their robust construction and precise markings, steel squares contribute to ensuring that windows and doors are properly aligned and securely fitted within the frame. However, it is worth noting that specific aspects of window and door framing may necessitate other specialized tools and techniques, such as shimming and leveling.

- Q:Can a steel square be used for cabinet hardware installation?

- Yes, a steel square can be used for cabinet hardware installation. A steel square, also known as a framing square or a carpenter's square, is a versatile tool that can be used for a variety of tasks in woodworking, including cabinet installation. It can be used to ensure accurate and square cuts, measure and mark lines, and check for level and plumb. When installing cabinet hardware, a steel square can be used to ensure that the hardware is properly aligned and spaced. Additionally, it can be used to measure and mark the location of holes for drilling. Overall, a steel square is a valuable tool that can assist in achieving precise and professional results in cabinet hardware installation.

- Q:Can a steel square be used for setting up a miter saw?

- Certainly! A miter saw can utilize a steel square for its setup. Known as a try square or carpenter's square, a steel square is a versatile tool that serves various woodworking purposes, including the setup of a miter saw. In setting up a miter saw, the steel square guarantees accuracy and alignment of the cutting angle. By positioning the square against the saw's fence and blade, it aids in determining if the blade is perpendicular to the fence. Moreover, the square assists in verifying the proper alignment of the miter gauge for precise angle cuts. In summary, a steel square plays a vital role in configuring a miter saw, ensuring precision and cleanliness in the cuts made.

- Q:How is a steel square used in woodworking?

- The steel square, a versatile tool in woodworking, serves various purposes. Its primary function lies in accurately measuring and marking right angles. To assess the squareness of a project or workpiece, one commonly employs a steel square. Woodworkers rely on it to verify the perfect 90-degree corners of furniture, such as tables or cabinets. This step is vital for securing stability and guaranteeing the overall quality of the final product. Furthermore, a steel square facilitates the process of laying out and marking angles. By positioning the square against the wood's edge, woodworkers can effortlessly denote precise angles, be it 45 degrees, 30 degrees, or any other desired measurement. This proves particularly advantageous when cutting or joining wood pieces at specific angles, as in the construction of frames or joints. Moreover, a steel square functions as a guide for executing straight and accurate cuts. Aligning the square along the wood's edge and utilizing a saw or another cutting tool along it ensures that the cuts remain perfectly perpendicular to the surface. This becomes especially crucial when striving for clean and precise cuts, whether for creating joints or sizing lumber. Overall, the steel square stands as an irreplaceable tool within woodworking. It plays a crucial role in achieving precision and accuracy in measuring, marking, and cutting wood, thereby guaranteeing the final project's superior quality and adherence to required specifications.

- Q:Can a steel square be used for checking the squareness of a deck frame?

- Yes, a steel square can be used for checking the squareness of a deck frame. The right angles and measurements on a steel square make it a reliable tool for ensuring the deck frame is properly aligned and square.

- Q:How do you use a steel square for marking roof eave angles?

- To use a steel square for marking roof eave angles, you will need to follow a few steps: 1. Start by positioning the steel square against the roof eave where you want to mark the angle. The long side of the square should be parallel to the roof eave. 2. Align the lip or heel of the square with the bottom edge of the eave. The lip is the shorter side of the square that has a 90-degree angle. 3. Hold the square firmly in place and ensure it is level and straight. 4. Use a pencil or marker to mark the angle on the roof eave by tracing along the lip or heel of the square. 5. Once the angle is marked, you can use a measuring tape or ruler to measure the angle or transfer the marked angle onto other materials if needed. 6. Repeat this process for any other roof eave angles you need to mark. Using a steel square for marking roof eave angles is a reliable method as it provides accurate measurements and ensures proper alignment. It is important to handle the steel square with care and make sure it is securely positioned to obtain precise markings.

- Q:Can a steel square be used for checking the alignment of a bandsaw table?

- Yes, a steel square can be used for checking the alignment of a bandsaw table. A steel square is a versatile tool that can be used for measuring and checking the squareness and alignment of various surfaces and objects. When it comes to a bandsaw table, a steel square can be placed against the table surface and the blade, allowing you to visually check if the blade is parallel to the table or if it is tilted. This is an important aspect of bandsaw operation as a misaligned blade can lead to inaccurate cuts and potential safety hazards. By using a steel square, you can quickly and easily determine if any adjustments need to be made to ensure the proper alignment of the bandsaw table.

- Q:Can a steel square be used for checking the squareness of a band saw table?

- Yes, a steel square can be used for checking the squareness of a band saw table. A steel square is a tool that is commonly used to check the accuracy and squareness of various surfaces and angles. To check the squareness of a band saw table, you would place the steel square against the edge of the table and compare it to the blade of the band saw. If the blade aligns perfectly with the edge of the steel square, then the table is square. However, if there is any gap or misalignment between the blade and the square, then the table is not square and adjustments will need to be made. It is important to ensure that the steel square is straight and accurate to obtain precise results.

- Q:What are some common markings found on a steel square?

- A steel square typically contains measurement scales, such as inches, centimeters, and millimeters. These scales are utilized to precisely measure and indicate dimensions on materials. Angles can also be measured or drawn on different surfaces using the angle markings, which generally range from 0 to 90 degrees. Moreover, steel squares often feature markings for rafter lengths, which are significant in carpentry for determining the length of rafters or roof framing components. These markings may appear as numbers or symbols, and their purpose is to guarantee exact and accurate measurements and markings when utilizing a steel square.

- Q:What are some common techniques for using a steel square in boat building?

- Boat builders commonly utilize a steel square in the construction process to ensure precise measurements and angles. The following are several techniques frequently employed in boat building when using a steel square: 1. Squareness assessment: Builders examine the squareness of bulkheads and frames by placing the steel square against their edges. This guarantees that these components are perfectly perpendicular to the boat's centerline. 2. Angle measurement: Accurate angle measurement can be accomplished by boat builders using a steel square. By aligning one leg of the square with the reference line and the other leg at the desired angle, they can mark the correct angle on the boat's structure. 3. Measurement transfer: Steel squares are employed to transfer measurements from plans to the boat's structure. Builders align the square with the reference line and then mark points, lines, or angles on the boat's components. 4. Bevel angle verification: In boat building, bevel angles are crucial, especially for joining planks or panels. A steel square can determine the correct bevel angle by aligning it with the reference line and adjusting until the desired angle is achieved. 5. Diagonal measurement check: Boat builders use a steel square to verify diagonal measurements on the boat's structure. By measuring both diagonals and ensuring they are equal, builders can confirm the boat's symmetry and accurate construction. 6. Component alignment: Steel squares are also employed to align components during boat assembly. Builders place the square against the edges of different parts to ensure perfect alignment before fastening them together. 7. Straight line creation: A steel square is a useful tool for drawing straight lines on boat components. Builders align one leg of the square with the material's edge, allowing them to easily draw a straight line parallel to it. In conclusion, a steel square is an indispensable tool in boat building as it aids boat builders in achieving accuracy and precision in their measurements, angles, and alignments.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 15 Million |

| Main Markets | Middle east; Southeast Asia; Africa; East Aisa |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20%-35% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 6,500 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Hot-rolled Square Steel Bar With Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords