Hot Dip Galvanized Steel Coil- in Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

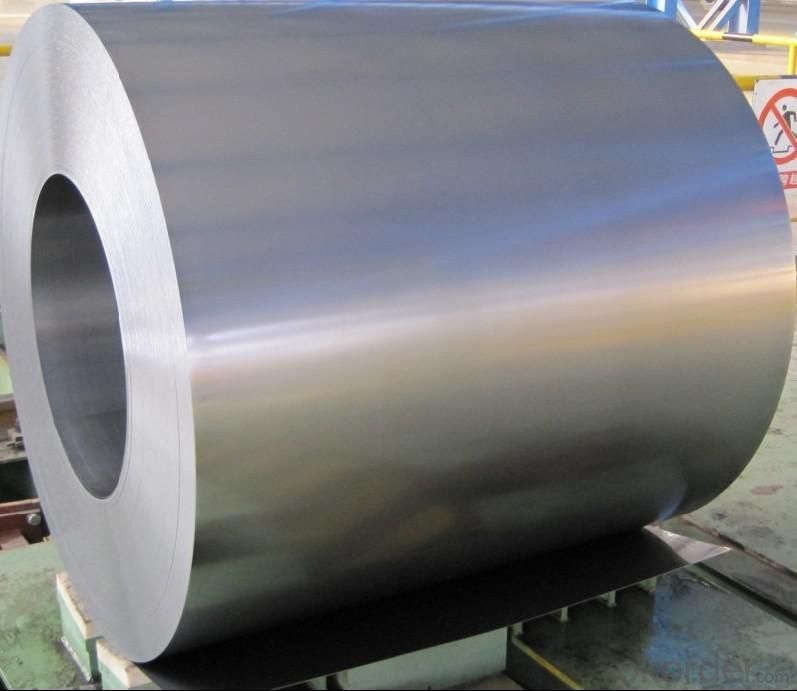

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

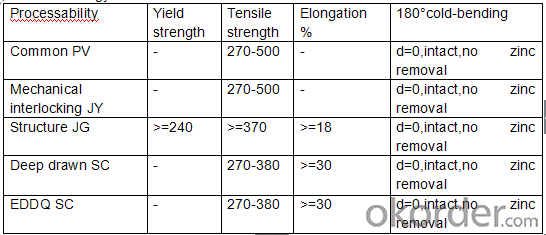

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:How do steel coils contribute to sound insulation in buildings?

- Steel coils can contribute to sound insulation in buildings due to their high density and ability to absorb and dampen sound waves. The compact arrangement of steel coils within walls or floors helps to reduce the transmission of sound, thus providing a barrier against noise and enhancing the overall acoustic performance of the building.

- Q:What are the different types of steel coil recoiling methods?

- There are several different types of steel coil recoiling methods, including oscillating recoiling, flying shear recoiling, and rotary recoiling.

- Q:What are the different types of steel coil cutting processes?

- Various industries utilize several different steel coil cutting processes. These processes include: 1. Shearing: The most widely used and simplest method of steel coil cutting involves utilizing a shear blade to cut the coil material into desired lengths. This can be done either manually or with the assistance of automated machinery. 2. Slitting: A process designed to cut wide coils into narrower strips, slitting involves passing the coil material through a set of circular knives that cut the steel into smaller coils or strips of the desired width. 3. Laser cutting: Renowned for its precision and efficiency, laser cutting involves using a high-powered laser to melt or vaporize the material along a predetermined path. This method is commonly employed for intricate designs or when high accuracy is required. 4. Plasma cutting: Another method of cutting steel coil involves using a plasma torch that generates a high-velocity jet of ionized gas to melt the material. Plasma cutting is known for its speed and ability to cut through thick materials. 5. Waterjet cutting: This process utilizes a high-pressure stream of water mixed with abrasive particles to cut through steel coil. Waterjet cutting is frequently chosen when the material being cut is sensitive to heat or when precision is necessary. 6. Saw cutting: A traditional cutting method, saw cutting involves using a saw blade with teeth to cut through the material. It is particularly effective for thicker materials and can be performed manually or with the aid of automated machinery. These represent just a few of the many steel coil cutting processes commonly employed. The choice of cutting method relies on several factors such as the material's type and thickness, desired accuracy, speed, and cost-effectiveness.

- Q:I want to experiment with making steel and want to especially make it stronger. And also I want to know if its possible to turn a meteorite into steel?

- If you're looking to make steel stronger, I can suggest 2 things: 1. If you're actually smithing the steel yourself, and forging it from hot liquid metal, then if you can get ahold of some Carbon (i have no idea where you can get some), you can add it to the molten steel to make it stronger. Sword Smiths did it all the time back in the Dark Ages. (you'll have to look up the exact Science and Process of how to do it) 2. There's a treatment for steel called Tempering. If you Temper the steel, it makes it stronger. You do this by 1st Forging what you're making. In this case, I'll use a sword. Take the Sword and re-heat it (i dont know the exact temperature) until it glows-hot. You can use a blast furnace, a campfire, or any other extreme-source of heat. Some companies use molten Salt - yes, the Condement, and dip the sword in it until it's glowing-hot. Now you have to super-cool it. This is simple, all you need is Ice water. Submerge the Sword in it, until it's cool to the touch. Now toss the Sword back into your source of extreme Heat. Get it glowing hot, and then take the sowrd out. Set it aside, and let it cool naturally. Once it's cooled, it's TEMPERED, and alot stronger. NOTE: If you stop at the ICE-WATER stage, you'll only succeed in making your Sword BRITTLE. You MUST Continue the Process once Started. - Hope this helps.

- Q:What are the cost considerations when purchasing steel coils?

- When buying steel coils, there are several factors to consider regarding cost. To begin with, the price per unit of steel coil is a significant consideration. The cost of steel coils can vary depending on factors such as the type of steel, grade, thickness, width, and length. Higher-grade steel coils tend to be more expensive than lower-grade ones, and thicker or wider coils can also come at a higher cost. Another cost consideration is the quantity of steel coils required. Purchasing larger quantities often comes with volume discounts, so it is important to determine the necessary quantity and assess whether it is more cost-effective to buy in bulk or smaller batches based on demand and storage capacity. Transportation costs should also be taken into account. The weight and size of the coils can impact shipping costs, especially for long-distance transportation. Additionally, the distance between the supplier and the buyer can affect freight charges, so it is crucial to evaluate different shipping options and choose the most cost-effective method. Furthermore, it is essential to consider any additional costs associated with processing or customizing the steel coils. For example, if the coils need to be cut, leveled, or coated, these extra services can add to the overall cost. Obtaining quotes from different suppliers and comparing prices for these value-added services is important. Lastly, the overall quality and reliability of the steel coils must be taken into consideration. Although cheaper options may seem more cost-effective initially, they may end up costing more in the long run if they do not meet required standards or have a shorter lifespan. Choosing reputable suppliers with a history of delivering high-quality products is advisable to ensure that the investment in steel coils is worthwhile. In conclusion, the cost considerations when purchasing steel coils include the price per unit, quantity discounts, transportation costs, additional processing services, and the overall quality and reliability of the coils. Thoroughly evaluating these factors will help make an informed decision that balances cost-effectiveness with the desired quality and specifications of the steel coils.

- Q:Recently I bought Bleach's Grimmjow's replica sword from swordsswords and I was wondering how strong is 440 steel when used for a 21 inch blade? Can it cut effectively? Is it dangerous?

- That is intended for display only. In other words it is useless for any other purpose. Stainless steel is only good for short knives. As it does not hold an edge and is not very strong.

- Q:How are steel coils used in the production of electrical transformers?

- Steel coils are used in the production of electrical transformers as they provide the core structure for the transformer. The steel coils are wound with insulated copper wire to create the primary and secondary windings of the transformer, which allow for the transformation of electrical energy from one voltage level to another. The steel coil helps to conduct and distribute magnetic flux within the transformer, ensuring efficient energy transfer and reducing losses.

- Q:Is boron steel or carbon steel a harder metal? Which one is more flexible?

- There is really no simple answer to this question. Boron is usually used for a handful of reasons, but most center on high volume low cost production of durable hardened steel. Boron is a very cheap way to get very durable parts with very minimal alloying of expensive materials. It was born of necessity during WW2 and is currently in WIDE use in bulldozer undercarriage. Probably in place of what would otherwise be 4140. Boron steel is quite a bit more difficult to properly heat treat. Better suited to mass production facilities with tight controls, but when done properly provides material just as durable as higher alloys. Not a backyard endeavor such as ht/tempering carbon steel or tool steels without appropriate homework and treatment controls.

- Q:Ok, so im gonna get my tragus pierced and i was wondering which is better, titanium or stainless steel. I hear like everyone uses stainless steel , but is titanium better?Thanks

- It seems like less people are allergic to titanium than surgical grade steel.

- Q:How are steel coils used in the production of wire products?

- Wire products rely heavily on steel coils, which are indispensable in their production. These coils, typically crafted from high-quality steel, serve as raw materials in wire drawing processes. Wire drawing, a manufacturing technique, diminishes the coil's diameter, converting it into diverse wire products. The initial step involves the placement of a steel coil onto a wire drawing machine. Subsequently, the machine pulls the coil through a sequence of progressively smaller dies. Each die the coil passes through reduces the wire's diameter, resulting in a more slender and elongated wire strand. This process can be repeated multiple times until the desired wire thickness is achieved. Once the wire is drawn, it can undergo further processing to create an array of wire products, including fencing, nails, screws, springs, and electrical wires. The wire can be cut into specific lengths, bent, or shaped to suit its intended purpose. Moreover, it can undergo treatments like galvanizing or coating to enhance its durability and resistance to corrosion. Steel coils offer numerous advantages in wire product manufacturing. Firstly, they provide a consistent and uniform material, ensuring the resulting wire products possess consistent quality and performance. Secondly, steel coils are easily transportable and can be stored efficiently, making them a cost-effective choice for manufacturers. Lastly, the versatility of steel enables the production of wire products with varying tensile strengths and properties to meet specific industry requirements. To summarize, steel coils play an essential role in wire product manufacturing. They serve as the primary raw material in wire drawing processes, where they undergo a series of reduction steps to be transformed into diverse wire products. These wire products find applications across various industries, solidifying the indispensability of steel coils in the manufacturing sector.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Dip Galvanized Steel Coil- in Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords