Hot-Dip Aluzinc Steel Coil Used for Industry with So High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Aluzinc Steel Coil Used for Industry

1.Structure of Hot-Dip Aluzinc Steel Coil Description

Hot-dip aluzinc steel sheet is substrated on cold rolled steel in various strength and specification. Coating composition is 55% aluminmum in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent and heat resistance performance.

2.Main Features of the Hot-Dip Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

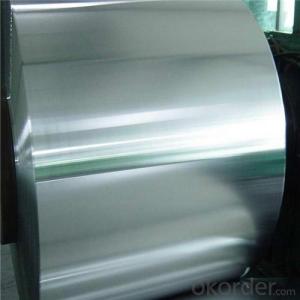

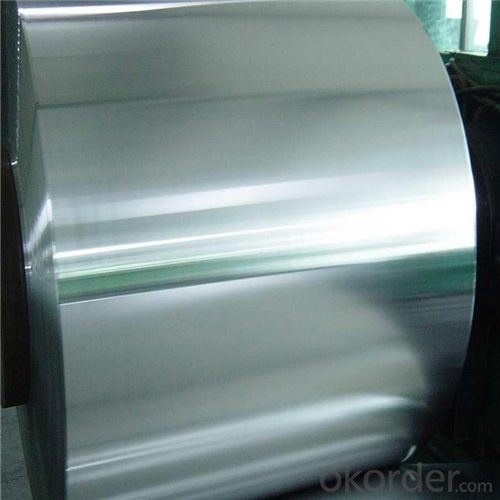

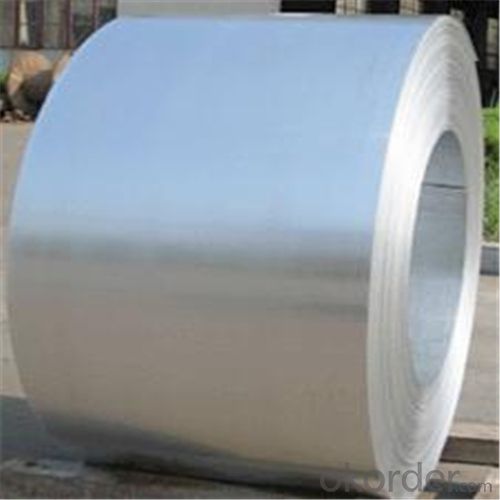

3. Hot-Dip Aluzinc Steel Coil Images

4. Hot-Dip Aluzinc Steel Coil Specification

Hot-Dip Aluzinc Steel Coil | |

Thicknenss | 0.16mm-3.5mm |

Width | 1250mm max |

Coating mass | 30-185g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory.

3.How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:How are steel coils protected from chemical damage?

- Steel coils are protected from chemical damage through various methods such as applying protective coatings, using corrosion inhibitors, and storing them in controlled environments to minimize exposure to harmful chemicals.

- Q:What are the quality control measures for steel coils?

- Quality control measures for steel coils typically include various inspections and tests to ensure that the coils meet the required standards and specifications. These measures often involve visual inspections to identify any surface defects or irregularities, such as cracks, dents, or scratches. Additionally, dimensional checks are performed to verify the coil's size, shape, and weight. Other quality control measures may involve conducting mechanical tests, such as tensile strength and hardness tests, to assess the strength and durability of the steel coils. Overall, these measures aim to guarantee that the steel coils are of high quality and suitable for their intended applications.

- Q:How are steel coils used in the manufacturing of construction bulldozers?

- Steel coils are used in the manufacturing of construction bulldozers as they provide the necessary strength and durability required for the heavy-duty components of the machine. These coils are typically shaped and welded to form the structural frame, blades, and bucket of the bulldozer, ensuring that it can withstand the rigorous demands of construction and earthmoving tasks.

- Q:Hi, does anyone know where i can find more about this topic ? fire resistant steels for structural applications. thanks

- There is a chemical that is used presently that is sprayed onto steel beams called Monocoat. Its a form of insulation that gives steel protection for up to 2 hours I think. Hope that helps!

- Q:I'm pretty sure that this topic has been beaten to death by now. But, I still can't get a definite answer. With stainless steel, you get better corrosion resistance, and you will hold and edge longer. With carbon steel, you will hold a sharper edge, and you could forge a knife blade longer than 2 ft without breakage. I'm personally a fan of stainless steel ( the 440 grade stuff ), just because it seems to hold up to use and abuse better in the long run. HOWEVER, I have NEVER had a factory made knife break on me. I don't think that they would try to sell you a knife that didn't do what it was meant to do, at least to a reasonable degree. (I work for a living, and can't afford a custom $600 knife.) What do you think? Is this a pointless topic? Will there ever be a winner?

- If your talking about a folding pocket knife, I think that it's basically six one way and a half dozen the other. I actually do prefer stainless for my pocket knives. I don't want to oil a knife to the degree I feel carbon requires, only to then stick it my pocket to attract dirt to the knife and oil to my pants. I'm the exact opposite on sheath knives though. I like 1095 carbon steel, plain edge sheath knives. I'll thrash on them HARD, and I rarely have major edge problems. Of course, I require them to be coated with some kind of powder coat or the like, because they can rust, but I do try and keep them clean and dry when in the sheath, so they won't pit the uncoated edge. My reasons for this sheath knife preference is multi-fold. First, these knives are simply affordable. I don't spend $80 dollars on a outdoors sheath knife. I use the tool too hard to want to spend more. I don't like the more traditional stainless steels such as AUS-8, 420HC, and 440C (not to mention the HORRENDOUS 440A) because I feel that the all else being equal, a stainless blade will bend before a carbon blade will break. I also think that carbon holds an edge at least as well, if not better, than traditional stainless, and it's much easier to hone. I don't know much about these new laminates, other than the very hard, but not so tough. They seem to be POSSIBLY too brittle for my use. That, combined with the fact that they cost a FORTUNE, means that I just won't be considering them.

- Q:How are steel coils used in the manufacturing of telecommunications equipment?

- Steel coils are used in the manufacturing of telecommunications equipment as they are commonly used as a raw material for various components, such as enclosures, cabinets, and brackets. The coils are processed and shaped to create the necessary parts that provide structural support, protection, and stability to the telecommunications equipment.

- Q:How are steel coils tested for quality?

- Steel coils are tested for quality through a variety of methods, including visual inspections, measurements of dimension and weight, and mechanical tests such as tensile strength and hardness. Additionally, non-destructive testing techniques like ultrasonic or magnetic particle testing may be used to detect any potential defects or flaws within the coils. These comprehensive testing procedures ensure that the steel coils meet the required quality standards before they are used in various industries.

- Q:What are the different methods of leveling steel coils?

- There are several methods of leveling steel coils, including roller leveling, stretcher leveling, and tension leveling. Roller leveling uses a series of rollers to gradually bend the steel to achieve a flat surface. Stretcher leveling involves stretching the steel through hydraulic or mechanical means to remove any residual stresses and straighten it. Tension leveling applies tension to the steel coil while passing it through a series of rollers, effectively elongating the material to remove any waviness or curvature.

- Q:Can steel coils be embossed?

- Yes, steel coils can be embossed. Embossing is a process that involves creating raised or sunken designs on a material, and it can be applied to steel coils to add texture or decorative patterns.

- Q:What are the different methods of protecting steel coils from corrosion?

- There are several methods for protecting steel coils from corrosion. One common method is applying a protective coating, such as zinc or epoxy, which acts as a barrier between the steel surface and corrosive elements. Another approach is using corrosion inhibitors, which are chemicals that can be added to the storage environment or applied directly to the steel to reduce the rate of corrosion. Additionally, proper storage conditions, such as controlling humidity levels and preventing exposure to moisture and chemicals, can also help protect steel coils from corrosion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-Dip Aluzinc Steel Coil Used for Industry with So High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords