Hot-Dip Aluzinc Steel Coil Used for Industry with Our High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

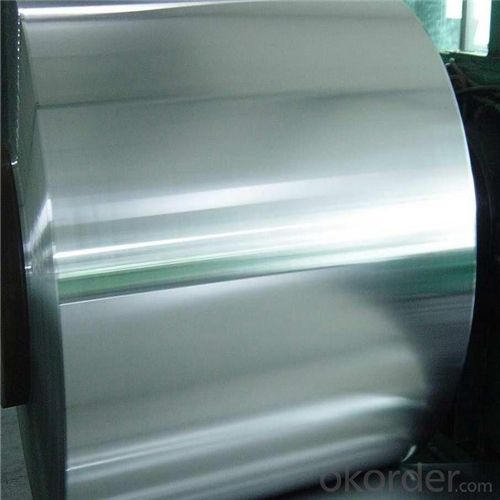

Hot-Dip Aluzinc Steel Coil Used for Industry

1.Structure of Hot-Dip Aluzinc Steel Coil Description

Hot-dip aluzinc steel sheet is substrated on cold rolled steel in various strength and specification. Coating composition is 55% aluminmum in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent and heat resistance performance.

2.Main Features of the Hot-Dip Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

3. Hot-Dip Aluzinc Steel Coil Images

4. Hot-Dip Aluzinc Steel Coil Specification

Hot-Dip Aluzinc Steel Coil | |

Thicknenss | 0.16mm-3.5mm |

Width | 1250mm max |

Coating mass | 30-185g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory.

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

- Q:What are the different types of steel coil slitting methods?

- There are three main types of steel coil slitting methods: rotary slitting, loop slitting, and oscillating slitting. Rotary slitting involves using a circular knife to cut the coil into smaller strips. Loop slitting involves creating a loop in the coil and then cutting it using a straight knife. Oscillating slitting involves using a reciprocating knife to make a back-and-forth motion while cutting the coil. These methods allow for precise and efficient slitting of steel coils into narrower strips.

- Q:How are steel coils processed for cutting to length or blanking?

- Steel coils are typically processed for cutting to length or blanking through a series of steps. First, the coils are unwound using a machine called an uncoiler, which feeds the steel into the cutting process. Then, the steel passes through a leveler to ensure a flat surface. Next, it enters a shear or blanking process, where the steel is cut into desired lengths or shapes. Finally, the cut pieces are stacked or packaged for further use or distribution.

- Q:How are steel coils used in the production of signage?

- Steel coils are used in the production of signage by being cut into sheets and then shaped into various sign components. These coils provide a durable and rigid material that can be easily manipulated and formed into different shapes, allowing for the creation of sturdy and long-lasting signs.

- Q:So I'm looking for some decently priced black motorcycle boots that have steel toes (and any additional protection) and look good in jeans. Pretty simple. Any recommendations?

- (add boots in top right search) If your looking for a dedicated motorcycle boot they have videos (top of line look for the high $) what they don't tell you is the added road feedback threw the soles and the small wear toe hard shift pad gives you feed back on the shift lever next to bare footed!

- Q:I know that mild steel is more brittle than cast iron....but that is all.......please help??Thank you in advance......Ruby:D

- Mild steel is iron that has had most of the carbon removed in an open hearth furnace or a Bessemer converter. It is mainly the carbon content that makes iron brittle (iron is brittle, not steel).

- Q:What are the different coil packaging options available for steel coils?

- There are several coil packaging options available for steel coils, including wooden crates, steel strapping, steel or plastic banding, shrink wrap, and stretch film. These packaging materials help protect the steel coils during transportation and storage, preventing damage from moisture, corrosion, and shifting.

- Q:Are steel coils used in furniture manufacturing?

- Yes, steel coils are commonly used in furniture manufacturing. They are often used as a support system in upholstered furniture such as sofas and mattresses to provide stability and comfort.

- Q:How are steel coils used in the production of automotive chassis?

- Steel coils are used in the production of automotive chassis as they provide the primary material for constructing the framework of the vehicle. These coils are first processed and shaped into the desired form, such as beams or plates, which are then welded together to form the chassis. The high strength and durability of steel make it an ideal choice for withstanding the stresses and loads experienced by the chassis, ensuring the safety and structural integrity of the vehicle.

- Q:What are the dimensions of steel coils used in automotive part manufacturing?

- The dimensions of steel coils utilized in the manufacturing of automotive parts may differ based on the particular application and manufacturer involved. Nonetheless, typical dimensions for steel coils in automotive part production lie within the range of 0.5 to 3 millimeters in thickness and 600 to 2000 millimeters in width. Additionally, the length of the coils can vary considerably, generally spanning from a few meters to several hundred meters. It is crucial to acknowledge that these dimensions are not set in stone and can be tailored to satisfy the specific demands of each automotive part being produced.

- Q:How are steel coils used in the manufacturing of industrial conveyors?

- Steel coils are used in the manufacturing of industrial conveyors as the primary material for the conveyor belts. They are formed into circular shapes and then cut into strips to create the belt. Steel coils provide strength, durability, and flexibility to the conveyor belts, allowing them to withstand heavy loads and operate smoothly.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-Dip Aluzinc Steel Coil Used for Industry with Our High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords