HLS180 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A wide range of Containerized Concrete Batching Plants which have production capacity from 60m³/h to 200m³/h with one mixer. In addition to this, the capacity can be 120m³/h, 160m³/h, 180m³/h, 300m³/h and 400m³/h in Containerized Concrete Batching Plants with double mixers on the same chassis.

These Containerized Concrete Batching Plants can be used to stir all types of concrete including dry hard concrete, fluid concrete, light aggregate concrete, and others. They are mostly preferred for high capacity concrete production requirements, for special projects and for the projects which will take a long time in the same location, such as large scale building construction, water power plants, airports, docks and bridges, as well as the large and medium scale precast concrete plants, ready-mix concrete plants and pipe piles production factories.

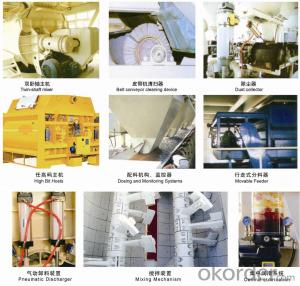

1. The host of the concrete mixing plant uses twin-shaft mixer and can produce many kinds of high-quality concrete, such as dry hard concrete and plastic concrete and others.

2. The aggregate is sent to the storage bins on the ground by the loading machine, and then is transferred to the aggregate storage buckets separately by belt conveyors and distributors;

3. Accumulative or separate metering methods can be used to measure aggregate through electronic weighing apparatus;

4. Capacity and quality of cement storage silos, and/or fly ash coal storage silos can be customized; powder materials are fed to weighing hoppers by screw conveyors for individual or cumulative measurement;

5. Water and the liquid additives are pumped to weighing hoppers for independent measurement;

6. Components and parts of famous domestic and international brands are incorporated to ensure the reliability and high production efficiency at sites:

(1) Main transmission is fitted with an Italian Bonfiglioli Brand planet gear speed reducer, which ensures high transmission efficiency, stable performance and has a strong resistance to overload.

(2) Air cylinder uses a Hymig or AIRTAC product which can be used for a long time with stable performance.

(3) The pneumatic components are from YSC or AIRTAC, which provide reliable performance with low levels of malfunction.

(4) The air compressor is a branded American Liebao product with a large air displacement capacity and steady operation.

(5) Schneider electric parts and Siemens PLC are adopted in our concrete mixing plant to ensure the reliable performance and high production efficiency.

7. Automatic production control system and feeding control system:

(1) The production control system adopts computer control and electronic scale measurement;

(2) The control system owns the functions of screen display, automatic free-fall correction, and equalize the sand containing water rate (The testing apparatus of sand containing water rate should be bought separately); manual are automatic control are both available during the mixing process;

(3) Equipped with the print system and four points monitor system to realize the central control and overall management of the whole plant, and the aggregate charging part is controlled by separated operator.

PRODUCT DETAILS:

1. Superior mixing performance

(1) Twin-shaft mixing host produce many kinds of high-quality concrete in high efficiency, such as dry hard concrete and plastic concrete and others, in high efficiency.

(2) It adopts an Italian Bonfiglioli Brand planet gear speed reducer which has the features of small volume, high efficiency and reliable performance;

(3) Its scale board and blades are made of wear-resistant casting alloys, ensuring high mixing efficiency and increasing durability;

(4) The shaft end is airproof and is completely sealed. The unique shaft-end bearing and seal design can greatly increase its durability;

(5) Overweight design provides excellent vibration absorption;

(6) Discharging door is controlled by a hydraulic pressure oil pump, equipped with three-point stop and manual open device;

(7) Centralized lubrication system adopts a 380V electric motor, which can pump the lubricate oil to the axes quickly.

2. Advanced and reliable electric control system

(1) The whole plant is controlled by computer or Siemens PLC.

(2) Manual control and automatic control systems are both available.

(3) Dynamic display panels and human-machine interface are used for the overall management and supervision of the plant functions and operations. Detailed operating information can be displayed, stored, output and printed.

(4) It has an automatic difference compensation function and can finish reserving tank production automatically.

(5) The control system, which is composed of an industrial touch screen and microcomputer, carries out the production control function to ensure reliability. When the microcomputer fails to control the normal production of the mixing plant, the industrial touchscreen can perform the function to ensure normal production, thus achieving the effect of double control by one machine.

3. Comfortable operating room

(1) Our operating room, which is totally enclosed, is fitted with an air conditioner in order to provide a working conducive environment.

4. Reliable and precise aggregate batching machine works automatically

(1) Pneumatic Batching Series: Pneumatic aggregate batching machine has a horizontal structure and adopts a cylindrical opening batching mode to batch materials. Three or four aggregate bins are available. (2) Electronic scales are used to carry out accumulative measurement or independent measurements. A programmed batching controller controls the process automatically. It has the features of high batching accuracy, short batching period and easy operation, etc.

(3) Motor Batching Series: Motorized aggregate batching machine is of a straight structure and can have two or three bins. Batching of materials is done through a belt conveyor. Electronic scales are used to carry out the function of accumulative measurement. The process is controlled automatically using a programmed batching controller. It has the characteristics of high batching accuracy, strong adaptability, easy operation and reliable performance, etc.

SPECIFICATIONS:

Model | HLS180 | |

Production capacity (m3/h) | 180 | |

Concrete mixer | Model | JS3000 |

Power (kW) | 2×55 | |

Output capacity (m3) | 3 | |

Aggregate size (gravel/cobble stone) (mm) | ≤60/80 | |

Batch bin | Capacity (m3) | 30 |

Belt conveyor deliverability (t/h) | 800 | |

Weighing scope and measuring accuracy | Aggregate (kg) | 4×(3000±2%) |

Cement (kg) | 1500±1% | |

Fly ash (kg) | 600±1% | |

Water (kg) | 600±1% | |

Admixture (kg) | 60±1% | |

Discharging height (m) | 3.8 | |

- Q:Of which do you partake most frequently? Killing, destroying, or wrecking machinery?

- Destroying in general =] Nothing wrong with a little destruction

- Q:Its said that computer chips run many things in todays society. From robots to mechanics. Command, geometric, graphics are programmed for a machine to do specific functions. A remote car / auto pilot moves when you push an electronic button. Do electronics really run today's society?

- Typically, the machinery is modified to provide position information, so that computers can read location, speed, orientation (angle) and other factors and use that data to provide power signals to run the machinery.

- Q:if service tax is applicable for the same ,then what is the percentage?

- It would run about 6 percent of the cost of the bill.

- Q:Are there any specific machinery that anthropologist have to work with?

- I am an anthropologist. For me, the most important equipment I carry is a notebook and a pen.

- Q:Where can I post pictures of an antique farm gear box and get replies as to :What is it? It was recently found under an old building. Everything seems to work freely.Ron

- can you identify the manufacturer? McCormick, McCormick Farm-all was one of the earliest manufacturers of farm machinery, you may find flecks or red paint. there should be identifying marks, google the manufacturer, who ever it is. It should work freely; if it is as old as i am thinking it was made of cast iron.

- Q:what is the difference between Turbo-machinery Engineer and rotating equipment engineer?

- Weird things happen when machinery is rotating has very high(turbo) speeds but both are similar but rotating equipment would probably be the foundation to turbo machinery.

- Q:but I'm here in the country?

- Farm machinery is very loud, so it might be that.

- Q:Last night I had a scary dream that someone broke into my house and was right outside my bedroom door. In my dream I grabbed my gun out of the nightstand. I had no problem getting the clip in, but when I tried to pull back on it to load a round into the chamber I had a very difficult time and I had to press the butt of the gun against my body so that I could use two hands to cock it back. At that point I knew immediatly I was in a dream and woke up. I always struggle with using firearms in my dreams and I have even pulled the trigger before and nothing happens.This is the same with driving cars. If I get into my car and attempt to drive in a dream I just can't do it. I can't control the vehicle for some reason. It will roll backwards or stall out. What could this mean and has anyone else experienced this?

- Not okorder Might help you. No one is a better expert at interpreting your dreams than yourself :)

- Q:What kinds of books do you need to study in mechanical design?

- Mechanical design manual 5, and then material mechanics, theoretical mechanics, mechanical principles, mechanical design - the University's teaching materials are very good, you can buy second-hand online to buy on the line. Specific industries, as well as construction machinery to hydraulic transmission, and some want to see the precision machinery design

- Q:The doctors were worried about his pancreas but say he is ok. He still feels quite bad after 1 month. Could his pancreas be more easily distressed with alcohol or just in general and could this cause him to feel light headed,nauseous and unwell

- That is a serious case that needs immediate attention by physician. Have him complete medical check up. So that everything will be taken care at hand. As the saying goes, An ounce of prevention is worth a thousand pounds of cure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HLS180 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords