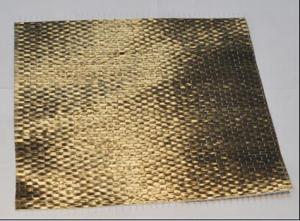

High Tempreture Resistance Basalt Unidirectional Fabrics

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Basalt fiber unidirectional fabric was woven basalt fiber by high-performance engineering materials, a tensile strength ≥ 2100Mpa, elastic modulus ≥ 105Gpa, elongation ≥ 2.6%. Basalt fiber production according to the follow-up required on a single uniform coated wire sizing, and sizing of various resins and Canada are matched with a coupling agent, give full play to basalt fiber unidirectional fabric enhancement. Basalt fiber unidirectional Bouilhou the way for replacement of carbon fiber reinforcement fabrics used in the construction and repair of bridges. Reinforcement in the construction field for the column of basalt fiber unidirectional fabric is very close to the seismic performance of reinforced carbon fiber unidirectional cloth.

Applications

Building bridges of consolidation, reinforcement and repair; radar cover, shipped machine parts, radar antenna; tanks armored body, structure, wheel hub, torque rods and bushings; sports skis, alpine skis, surfboard, etc.. Basalt fiber unidirectional fabric of basalt fiber products is currently the most mature product.

1.Cover board, manhole and handhold sealing materials in high temperature, high pressure stove tank, caldron, etc.

2.High temperature resistant thread, rope and belt

3.Corrosion and friction resistant rope and packing set

4.High temperature resistant sewing threads

5.Bundling electric motor coils an deep well hoisting rope slings

Performance

Basalt fiber unidirectional fabric of the technical indicators

Areal density (g/m2) | Single fiber diameter (μm) | Tensile strength (Mpa) | Elastic modulus (Gpa) | Elongation rate (%) | Thickness (mm) |

260 | 13 | 2100 | 105 | 2.6 | 0.100 |

300 | 13 | 2100 | 105 | 2.6 | 0.115 |

360 | 13 | 2100 | 105 | 2.6 | 0.138 |

380 | 13 | 2100 | 105 | 2.6 | 0.146 |

FAQ

1. How long is warranty period?

We provide 3 year warranty period.

2. What is your MOQ?

Our MOQ is 4000 kgs.

- Q:Fiber has the difference between twist and twist

- The roving is divided into direct roving (also called direct yarn) and plied rovingDirect roving is defined as: parallel filaments and twisting and formed cluster body, no direct roving raw silk production process is relatively simple, products made of high strength glass steel products, can be directly applied to the winding and pultrusion process, can be directly used for cloth (i.e. roving fabric, commonly known as Plaid), therefore is widely used.

- Q:What resin fiber powder can be used for?

- 扔掉

- Q:Is glass steel a glass?

- Toughened glass is stronger than ordinary glass. One advantage is strong, and the two is broken, will not produce the tip of the debris, so that people are relatively safe.

- Q:Introduction of inorganic glass fiber reinforced plastic air pipe

- Inorganic glass fiber reinforced plastic air pipe, according to the properties of the binding materials, can be divides into: Made of binding materials with glass fiber mesh cloth hydraulicity inorganic glass steel duct and made of cementitious materials and glass fiber mesh air hardening modified magnesium oxychloride cement duct with two types of modified magnesium oxychloride cement to the sulfate type. The pH value of the hardened material should be less than 8.8, and there is no alkalinity corrosion of the glass fiber. Inorganic glass steel duct should be used alkali-free, medium alkali or alkali resistant glass fiber mesh cloth, and are consistent with current national standard "glass fiber grid" JC561, "the alkali free glass fiber roving," JC/T281, "in the alkali glass fiber roving" JC/T576 regulations. The quality of magnesium oxychloride cement duct Magnesium Oxide should comply with the national standard "Magnesium Oxide" light burned magnesite products with WB/T1019-2002 regulations. Inorganic glass steel duct can divided into the overall common type (non insulation), integral insulation type (inner and outer surface of inorganic glass steel, middle insulating material) and combination type (by special adhesive, composite plate, flange, reinforcement angle etc) and the combination of insulation, its production parameters should comply with the provisions of the table 1, 2, 3. The longitudinal and transverse lap joint distance between adjacent layers of glass fiber grid cloth should be more than 300mm, and the distance of the same layer lap joint shall not be less than 500mm. Lap length should be greater than 50mm. The wind pipe surface thickness of the slurry flating glass fiber mesh cloth is appropriate. And the surface do not have dense pores and spillage.

- Q:What is the production process of FRP grille?

- Continuous filament winding process (which belongs to the continuous method) that this process is a pipe in the movement through a supply of resin prepreg roving, feeding chopped glass steel fiber and resin sand mixture station, the pipe is made in a mould in continuous progress.

- Q:Nominal interpretation of fiber reinforced concrete

- Mix composite materials with random and uniform distribution of short fiber in cement concrete, including steel fiber reinforced concrete. Technical specification for fiber reinforced concrete structures CECS.

- Q:Production process of glass fiber reinforced plastic

- Simple glass reinforced plastics are melted together again

- Q:What are the advantages of the glass?reinforced?plastics antenna? What is the difference between an ordinary antenna and a glass?reinforced?plastics antenna?

- waterproof. structure of the antenna is different from the conventional vertical antenna, but the principle is the same. They all are sealed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Tempreture Resistance Basalt Unidirectional Fabrics

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords