High-temperature-resistant Polyester Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Description:

Polyester tape. With the pull of the steel belt, and the flexibility of PP. To overcome the traditional steel belt elasticity difference. Corrosion, high cost, is gradually replaced by steel tape. In the paper, iron and steel, printing, wood and other extensive areas have been widely used

2. Product Characteristic:

1 save cost: 1 tons of steel with the length equal to 6 tons of steel, greatly reduce the cost of packaging. Plastic steel belt 6 times lighter than the proportion of steel, so steel belt than strip to save 50%.

2. Tensile strength: with strip and the same tensile strength and good ductility., not easy to break.

3 corrosion resistance: steel packing belt in the air is easy to rust, pollution packaging. The steel belt is bright color, corrosion resistance, no harm to the packaging.

4. Connection: can be made of steel with extruded, manual available, desktop balers and automatic packing machine for hot melt connection.

5. Good safety: plastic steel belt strip and has the same tensile 5% tightening force is maintained over a long period of time, not back to the pine, hit by a strong external and 5% buffer elongation, ensure goods safety.

3.Specification :

Property | Unit | 0.045mm | 0.055mm | 0.06mm |

Thickness | mm | ±0.005 | ±0.005 | ±0.005 |

Tensile Strength | N/cm | ≥60 | ≥65 | ≥70 |

Elongation | % | ≥8 | ≥8 | ≥8 |

Peel Strength | N/cm | ≥200 | ≥200 | ≥200 |

Stainproof | - | good | good | good |

Shelf Life | day | 180 | 180 | 180 |

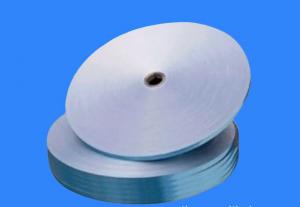

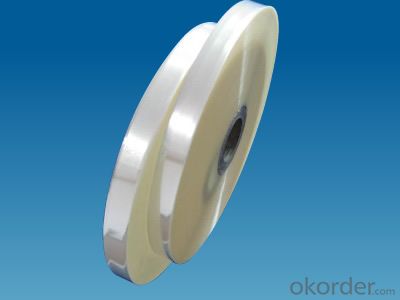

4. Reference Picture:

- Q:What material is the packing belt made of?

- Polypropylene is a thermoplastic resin made by the polymerization of propylene. According to the location of the methyl group into isotactic polypropylene (isotactic, polyprolene), random polypropylene (atactic polypropylene) and syndiotactic polypropylene (syndiotactic, polypropylene) three kinds.The arrangement of methyl groups on the same side of the molecular backbone is called isotactic polypropylene. If the methyl group is arranged in random order on both sides of the backbone, it is called atactic polypropylene, and when the methyl group is arranged alternately on both sides of the backbone, syndiotactic polypropylene is called. In general industrial polypropylene resins, the isotactic structure is about 95% and the remainder is atactic or syndiotactic polypropylene. Industrial products are based on isotactic substances. Polypropylene also includes copolymers of propylene with a small amount of ethylene. Usually translucent, colorless solid, odorless, non-toxic. The melting point can be as high as 167 DEG C because of the highly crystalline structure. Heat resistance and corrosion resistance, products can be steam disinfection is its outstanding advantages. Small density, is the lightest general plastic. The disadvantages are low temperature resistance, low impact and easy aging, but can be overcome by modification.

- Q:The harm of plastic packing belt to human body

- The plastic strapping belt is very poisonous to the human body. If you eat it, you will die and never turn over.

- Q:What is the reason that the packing machine can not be put in?

- It may be the wrong model of the packing belt, too wide or too thick, or the way to wear it is wrong. The Qingdao moxa packing machine, in general, has a detailed picture of the inside of the packing machine door, which can be referred to.

- Q:What types of Baling straps are used for packing?

- Galvanized belt (also called iron straps). Steel is easy to rust in air and water, and the corrosion of zinc in the atmosphere was only the corrosion rate of steel 1/15 in the atmosphere, is the use of micro thick galvanized steel galvanized layer of protection against corrosion of steel.

- Q:What is the standard of plastic strapping?

- The economic benefit is good. The length of the 1 ton PET packing belt is equal to 6 tons. The length of the steel strip of the same size is lower than that of the steel band per meter by 40%, and the packing cost can be reduced.

- Q:Blue belt principle is what?

- Blue will be packaged with packaging with heating to proper temperature in the air - water vapor to form a blue layer of the surface process.

- Q:Packing belt

- Packing belt (PP, PET) is divided into PP packing belt (also known as polypropylene packing belt) and PET strap (also called plastic packing belt), respectively using polypropylene and polyester PET for the production of raw materials, which are suitable for different heavy objects need to pack.Atlas of packing belt (4 pieces)Brief description: PP packing belt and PET packing belt are all kinds of plastic environmental protection packing belts which are widely used. PP packaging belt has been produced in China for more than 30 years, and PET belt has been produced in China for more than 20 years.

- Q:What kind of joints are used in the packing belt?

- Hot dip lap pack.Hot melt lapped by electrothermal welding, packing machinery high-frequency welding and ultrasonic welding and heating method, plastic surface heat melting, two with end face lapping up melting under pressure, to maintain a certain period of time, to be melted surface condensation, adhesive plastic belt joint way. Features: hot lap package is a package of new, suitable for polypropylene plastic bag, polypropylene plastic belt with iron because if the button is fixedly connected with the mechanical strength, only 50% of that of the base material, adhesive connection does not apply. The excuse is firm and beautiful, but it can not be untied.

- Q:Is packing with a shelf life?

- And iron belt, according to the different materials, packaging belt storage time is not the same.

- Q:Baling machine; packing belt; tightness adjustment

- The belt of the fully automatic baler is jammed and can not be used as a normal conveyor belt.1. remove the nuts associated with the stationary roller in sequence;2. it will be found that there are two special countersunk screws on the connecting shaft, because it is used for fixing the shaft mouth, so you need to turn the screw up;3., then you can remove the connecting shaft, check the tape stuck reasons, if there are foreign bodies can also be quickly cleared;4., in accordance with the original operation steps, and then re assembled fully automatic packaging machine, the main nut and curved plate to maintain a certain gap between. At least greater than the thickness of the bale used

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-temperature-resistant Polyester Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords