Aluminum/Polyester Composite Belt

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Description:

Usually as a middle layer the data according to the requirements, composite bag mainly film substrate: outer printing BOPA film BOPETBOPP inner heat sealing film CPPPE and co extruded film. AL aluminum foil) is one of them. Plastic bucket sealing machine through the glue composite film!

2. Product Characteristic:

1. Aluminum foil bag with metallic luster. And the aluminum foil bag printing color is more exquisite and bright. Maintenance performance is strong.

2 .aluminum foil bag is good. Has the characteristic of gas and water vapor impermeable, blister sealing machine which can effectively prevent the contents of moisture absorption and gasification and less susceptible to bacterial and insect pests, shape, and good stability, is not affected by changes in humidity.

3. Using the shielding or elution of local aluminum

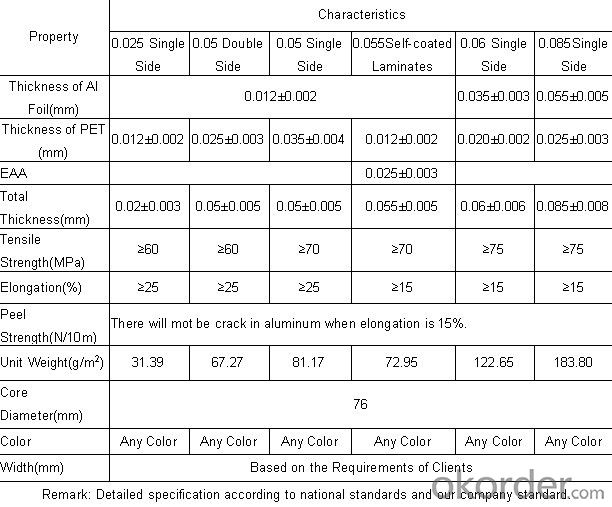

3.Specification :

4. Reference Picture:

- Q:Production process of PP packing belt

- Finally, the embossing, stretching after the packaging belt, after two patterns of pressure roller, it will be pressed on the pattern, its role is to increase friction in use, do not slip, from the appearance of looking handsome.

- Q:What types of Baling straps are used for packing?

- Galvanized belt (also called iron straps). Steel is easy to rust in air and water, and the corrosion of zinc in the atmosphere was only the corrosion rate of steel 1/15 in the atmosphere, is the use of micro thick galvanized steel galvanized layer of protection against corrosion of steel.

- Q:What is the standard of plastic strapping?

- Characteristic(1) strong tensile resistance, both tensile resistance of the steel band, but also the ductility of the impact resistance, but also to ensure the safety of transport products.(2) the elongation is small, the elongation is only 1/6 of the polypropylene band. It can keep the tension for a long time.(3) strong heat resistance, melting point of 260 degrees, 120 degrees below using deformation.(4) good safety, no steel belt rust, contamination of tied objects, bright colors.

- Q:What adhesive tape do you use?

- Common polyethylene, polypropylene resin as the main raw material, but also to nylon and polyester, polyester and the tensile strength of nylon strap, and polyethylene and polypropylene strapping polypropylene with low cost, good elasticity, can be selected according to different material strapping needs. ;

- Q:Permanent packaging machine packaging belt is not in place, how to repair?

- Incorrect wearing.Open the right door, in accordance with the instructions on page fifth marked "threading process" or the right door in the side wear band diagram, the right to wear.

- Q:Blue belt principle is what?

- Blue will be packaged with packaging with heating to proper temperature in the air - water vapor to form a blue layer of the surface process.

- Q:Why is plastic strapping broken?

- Plastic steel belt itself is elastic, broken tension standard 1608 plastic tape, breaking tension to close to 200kg.

- Q:What's the difference between hand packed belts and machine packs?

- The packing belt can be divided into a manual packing belt and a machine packing belt according to the different types of the packer.

- Q:Plastic packing belt and plastic belt packing the same? What is the difference?

- Plastic packaging belt, also known as PET packaging belt, in plastic packaging belt inside, the intensity is the best, is currently popular in the world instead of steel belt new belt. By virtue of its low cost, beautiful and durable, recycling, high degree of automation, widely used in steel, aluminum, chemical fiber, cotton, tobacco, paper, metal cans and other industries.

- Q:What's the function of the carton packing belt?

- Carton packing belt is mainly used for bundling cartons, strapping goods and convenient transportation, PE automatic end zone since 1989 from Japan and Taiwan to introduce automatic strapping machine after use, is characterized in that the demand is high, if not the use of new raw material for the production of the end zone will make the knotter strapping machine is worn, but also cause the operation is not smooth, tardy, error. With the recent years in the end of PE automatic carton packaging, printing and packaging, washing industry, towel factory, more and more vermicelli factory, manufacturers gradually increased

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum/Polyester Composite Belt

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords