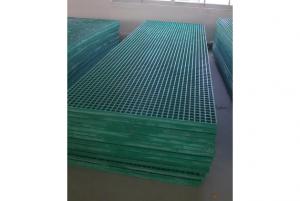

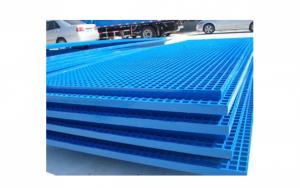

High Strength FRP Pultruded Grating with High Quality/ Good Shapes/All kinds of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Itroduction

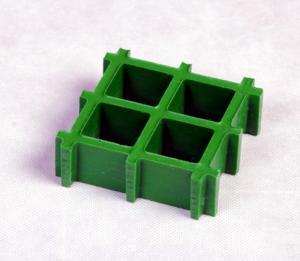

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

- Safety & Anti-slip

Electrical Insulating

Aging Resistance

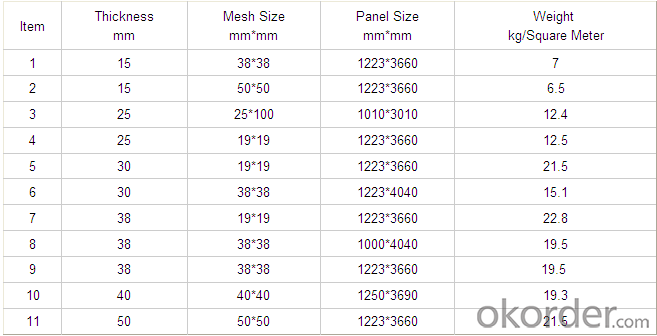

Specification

Advantage

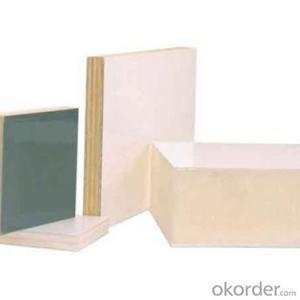

coated with prevent aging layer

excellent insulating performance

- long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

- All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

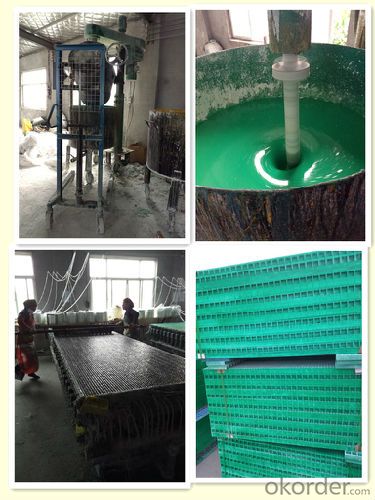

PROCESS

FACTORY

- Q:Are FRP pultrusion profiles fire resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are fire resistant. The combination of the reinforcing fibers and the polymer matrix used in FRP pultrusion profiles provide them with excellent fire resistance properties. These profiles are manufactured using a process known as pultrusion, which involves impregnating reinforcing fibers such as fiberglass or carbon fiber with a thermosetting resin. This resin undergoes a curing process, resulting in a strong and durable composite material. One of the key advantages of FRP pultrusion profiles is their inherent fire resistance. The thermosetting resin used in the manufacturing process has properties that make it highly resistant to fire. When exposed to flames or high temperatures, the resin does not melt or burn easily, thus preventing the spread of fire. Additionally, the reinforcing fibers in FRP profiles also contribute to their fire resistance. Fiberglass, for example, is an inorganic material that does not burn. It acts as a barrier against heat transfer and helps to minimize the spread of flames. Furthermore, FRP pultrusion profiles can be engineered to meet specific fire safety standards and regulations. By incorporating additional fire retardant additives or using specialized resin systems, the fire resistance of these profiles can be further enhanced. It is important to note that while FRP pultrusion profiles are fire resistant, their exact fire rating may vary depending on the specific composition and design. Therefore, it is essential to consult with manufacturers or suppliers who can provide detailed information about the fire resistance properties of their FRP pultrusion profiles.

- Q:Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical manufacturing?

- FRP pultrusion profiles are well-known for their resistance to chemicals utilized in the pharmaceutical manufacturing industry. These profiles are created by saturating fibers with a resin matrix, typically polyester or vinyl ester. This resin matrix offers exceptional chemical resistance, allowing the profiles to endure exposure to a wide variety of chemicals, including acids, alkalis, solvents, and cleaning agents frequently employed in pharmaceutical manufacturing procedures. Due to the combination of fiber reinforcement and a chemical-resistant resin matrix, FRP pultrusion profiles are an excellent option for applications that involve contact with aggressive chemicals. Unlike traditional materials such as steel or wood, FRP profiles do not corrode or undergo chemical reactions when in contact with substances. Moreover, FRP pultrusion profiles provide numerous additional benefits for pharmaceutical manufacturing applications. They possess a remarkable strength-to-weight ratio, are non-conductive, and exhibit high mechanical resistance. Furthermore, FRP is a non-porous material, preventing the absorption or release of chemicals. This characteristic is crucial for maintaining strict hygiene standards and preventing contamination in pharmaceutical processes. In conclusion, FRP pultrusion profiles are a dependable and long-lasting choice for pharmaceutical manufacturing environments, offering excellent resistance to the chemicals typically encountered in these processes.

- Q:Can FRP pultrusion profiles be used in the oil and gas industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the oil and gas industry. FRP pultrusion profiles offer several advantages that make them suitable for applications in this industry. Firstly, FRP pultrusion profiles are corrosion-resistant. They do not rust, corrode, or degrade when exposed to harsh environments, such as saltwater, chemicals, and extreme temperatures. This makes them ideal for use in offshore platforms, pipelines, and other oil and gas facilities where corrosion can be a significant issue. Secondly, FRP pultrusion profiles have high strength-to-weight ratio. They are lightweight yet extremely strong, allowing for efficient installation, transportation, and handling. This is particularly beneficial in the oil and gas industry, where weight reduction is a crucial factor in improving operational efficiency and reducing costs. Thirdly, FRP pultrusion profiles can be customized to meet specific requirements. They can be manufactured in various shapes, sizes, and configurations, making them versatile for different applications in the oil and gas industry. Whether it is for structural supports, grating, handrails, or other components, FRP pultrusion profiles can be tailored to fit the specific needs of each project. Furthermore, FRP pultrusion profiles offer excellent electrical insulation properties. This is important in the oil and gas industry, where electrical safety is paramount. FRP profiles can provide insulation and prevent electrical conductivity, reducing the risk of accidents and ensuring the safety of personnel and equipment. Overall, FRP pultrusion profiles have proven to be reliable, durable, and cost-effective solutions for various applications in the oil and gas industry. Their corrosion resistance, high strength-to-weight ratio, customization capabilities, and electrical insulation properties make them an attractive choice for this demanding industry.

- Q:Are FRP pultrusion profiles resistant to impact and vibration?

- FRP pultrusion profiles possess a high level of resistance to impact and vibration, thanks to their composition and manufacturing process. These profiles are inherently durable and strong due to the combination of resins and fibers used. The fibers, commonly glass or carbon, contribute to their excellent tensile strength, while the resin matrix adds toughness and impact resistance. The unique composition of FRP pultrusion profiles allows them to absorb energy effectively, enabling them to withstand impacts without significant deformation or damage. This quality makes them well-suited for applications that necessitate impact resistance, such as construction, transportation, and infrastructure projects. Furthermore, FRP pultrusion profiles exhibit exceptional vibration resistance. The composite material's inherent damping characteristics help disperse and dampen vibrations, minimizing the risk of structural fatigue and increasing the profiles' lifespan. This makes them ideal for use in environments with heightened vibration levels, including industrial machinery, bridges, and marine structures. Nevertheless, it is crucial to consider that the impact and vibration resistance of FRP pultrusion profiles may vary based on factors such as resin type, reinforcement fibers, and profile design. Thus, it is advisable to consult the manufacturer or supplier to ensure that the chosen FRP pultrusion profiles fulfill the specific impact and vibration resistance requirements of the intended application.

- Q:Are FRP pultrusion profiles resistant to high-pressure water jets?

- Yes, FRP pultrusion profiles are generally resistant to high-pressure water jets due to their inherent corrosion resistance and ability to withstand harsh environmental conditions.

- Q:Are FRP pultrusion profiles resistant to oil or fuel spills?

- FRP pultrusion profiles exhibit a general resistance to oil or fuel spills, which is well-known in the industry. This is due to their exceptional chemical resistance, particularly against oils and fuels, which is attributed to the combination of the polymer resin and reinforcing fibers. This unique blend creates a robust and enduring material capable of withstanding exposure to various substances. The impermeable nature of FRP pultrusion profiles is another significant advantage, making them impervious to oil and fuel. Consequently, even in the event of a spill, these profiles will not absorb the substances, thus preventing any potential harm or deterioration. Furthermore, FRP possesses corrosion resistance and does not react with oils or fuels, ensuring its longevity and performance. These remarkable qualities make FRP pultrusion profiles highly sought after in industries where oil or fuel spills are a concern, such as oil refineries, chemical plants, and offshore platforms. They provide a dependable solution for applications requiring resistance to chemical exposure, offering a cost-effective and low-maintenance alternative to conventional materials.

- Q:How do FRP pultrusion profiles perform in high-vibration applications?

- High-vibration applications are where FRP (Fiber Reinforced Polymer) pultrusion profiles truly excel. The exceptional properties of FRP materials make them an ideal choice for these situations. To begin with, FRP pultrusion profiles are renowned for their impressive strength-to-weight ratio. Unlike traditional materials like steel or aluminum, FRP profiles are significantly lighter while still possessing remarkable strength and rigidity. This lightweight quality reduces the overall mass of the structure, resulting in lower vibration amplitudes. Furthermore, FRP materials boast outstanding damping characteristics. Damping refers to a material's ability to dissipate energy and decrease vibration amplitudes. In comparison to other materials, FRP pultrusion profiles have a higher damping coefficient, meaning they can more effectively absorb and dissipate vibrations. This minimizes the transmission of vibrations throughout the structure, reducing the risk of resonance and fatigue failure. In addition, FRP pultrusion profiles demonstrate exceptional resistance to fatigue and corrosion. Vibrations can cause cyclic loading, which can lead to fatigue failure over time. However, the inherent properties of FRP materials, including their excellent tensile strength and resistance to environmental factors, make them highly resilient to fatigue and corrosion. This guarantees the longevity and durability of the profiles, even in high-vibration environments. Moreover, FRP pultrusion profiles offer immense design flexibility, allowing for customized shapes and sizes that can be tailored to specific applications. This flexibility allows engineers to optimize the profiles' performance in high-vibration scenarios by adjusting the geometry and composition to enhance their dynamic characteristics. In summary, FRP pultrusion profiles are exceptionally suited for high-vibration applications due to their lightweight nature, excellent damping characteristics, resistance to fatigue and corrosion, and design flexibility. These profiles provide a reliable and durable solution that can effectively withstand the challenges posed by vibrations, ensuring safe and efficient operation in such environments.

- Q:Can FRP pultrusion profiles be used in chemical storage tanks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in chemical storage tanks. FRP pultrusion profiles are known for their excellent corrosion resistance, making them suitable for storing a wide range of chemicals. They are also lightweight, strong, and have a high strength-to-weight ratio, which makes them an ideal choice for constructing durable and long-lasting chemical storage tanks. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in tank design and construction. Overall, FRP pultrusion profiles are a reliable and cost-effective option for chemical storage tanks due to their corrosion resistance, strength, and customization capabilities.

- Q:Can FRP pultrusion profiles be used in modular construction?

- Yes, FRP pultrusion profiles can be used in modular construction. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. These properties make them suitable for various applications in modular construction, including structural elements, cladding, and panel systems. Additionally, FRP pultrusion profiles can be easily molded into different shapes and sizes, making them compatible with the modular construction approach, where standardized components are assembled to create a larger structure.

- Q:Are pultruded FRP sections strong? What are its main areas of application?

- More fields. Advantage is obvious, if the corrosion resistance, insulation resistance, quality is lighter than steel; strength and steel strength comparable;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Strength FRP Pultruded Grating with High Quality/ Good Shapes/All kinds of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords