GRP Molded Grating for All Kinds Of Waterproof Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

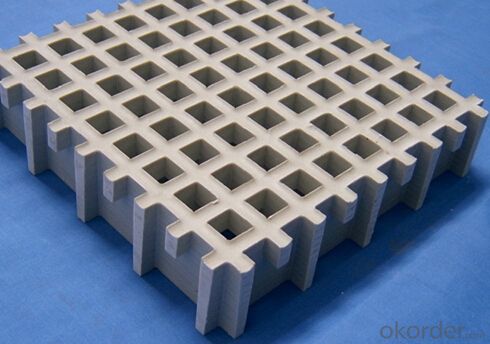

Product description of FRP Grating

FRP Grating, Molded FRP Grating, Fiberglass Grating, GRP Grating,GRP Molded Grating,FRP Pultrusion Grating, FRP Mini Mesh Grating,Trench Grating, Drain Grating,Grating Walkway, Platform Grating...

Comparing with other floor materials, FRP molded grating provides a series of benefits, unmatched impact resistance,

while the strength-weight-ratio is only one-fourth of that of steel grating. It is easy to cut and install.

Specification of FRP Grating

Item | Thickness mm | Mesh Size mm*mm | Panel Size mm*mm | Weight kg/Square Meter |

01 | 15 | 38*38 | 1223*3660 | 7 |

02 | 15 | 50*50 | 1223*3660 | 6.5 |

03 | 25 | 25*100 | 1010*3010 | 12.4 |

04 | 25 | 19*19 | 1223*3660 | 12.5 |

05 | 30 | 19*19 | 1223*3660 | 21.5 |

06 | 30 | 38*38 | 1223*4040 | 15.1 |

07 | 38 | 19*19 | 1223*3660 | 22.8 |

08 | 38 | 38*38 | 1000*4040 | 19.5 |

09 | 38 | 38*38 | 1223*3660 | 19.5 |

10 | 40 | 40*40 | 1250*3690 | 19.3 |

11 | 50 | 50*50 | 1223*3660 | 21.5 |

Images

Features

1.Corrosion and Chemical resistant

2.Slip-resistant

3.High strength-to-weight ratio

4.Ergonomic

5.Low maintenance

6.Fire retardant

7.Easily fabricated and installed

FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. Payment terms?

We can accept L/C, T/T etc.

- Q:What is the maximum length of FRP pultrusion profiles that can be manufactured?

- The length at which FRP pultrusion profiles can be manufactured is influenced by various factors, including the specific manufacturing process, equipment capacity, and transportation limitations. Generally, these profiles can range in length from a few feet to several hundred feet, but there are practical limitations that must be taken into account. Firstly, the size and capacity of the pultrusion equipment used in the manufacturing process often determine the length restrictions of the profiles. Different pultrusion machines have different capabilities, with length capacities varying from a few feet to over 100 feet. Manufacturers must consider the limitations of their available equipment when determining the maximum length they can produce. In addition, transportation and logistical constraints can also impact the maximum length of FRP pultrusion profiles. Longer profiles can be more difficult to transport due to restrictions on road transport, shipping containers, or handling capabilities. These limitations may vary depending on the region, infrastructure, and available transportation methods. It is worth noting that longer profiles may also face challenges in terms of quality control and dimensional stability during the manufacturing process. As the length increases, it becomes more challenging to maintain consistent mechanical properties and effectively control the curing process. Therefore, while there is no fixed maximum length for FRP pultrusion profiles, it is crucial for manufacturers to consider the technical capabilities of their equipment, transportation logistics, and quality control factors when determining the practical limit for the length of their products.

- Q:How to install GRP mark pile

- The possibility of theft (because of the pultruded glass steel material is square or triangle pipe is hollow know who stole 1. useless also know this thing is not plastic can not sell 2. take home cushion not after all not solid no component)

- Q:Are FRP pultrusion profiles impact resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high impact resistance. The combination of strong reinforcing fibers and a polymer matrix makes them highly durable and able to withstand significant impact forces without breaking or deforming.

- Q:Can FRP pultrusion profiles be used in the construction of elevated walkways?

- Yes, FRP pultrusion profiles can be used in the construction of elevated walkways. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various construction applications including elevated walkways. They are lightweight, yet strong enough to support pedestrian traffic and withstand environmental conditions. Additionally, FRP pultrusion profiles can be easily customized to meet specific design requirements, making them a popular choice in the construction industry.

- Q:Can FRP pultrusion profiles be used in automotive applications?

- FRP pultrusion profiles can indeed be utilized in automotive applications, presenting a myriad of advantages that render them appropriate for such use. Firstly, these profiles possess the dual attributes of being lightweight and strong, which holds immense significance within the automotive industry. As weight reduction stands as a top priority for enhancing fuel efficiency and performance, the commendable strength-to-weight ratio of FRP profiles enables the creation of lighter vehicles that consume less fuel. Secondly, FRP pultrusion profiles exhibit exceptional corrosion resistance, a vital characteristic for automotive applications routinely encountering exposure to various chemicals, moisture, and harsh environments. This corrosion resistance ensures the long-term dependability and durability of the profiles, ultimately reducing maintenance expenses and prolonging the lifespan of automotive components. Moreover, FRP pultrusion profiles offer remarkable design flexibility, thereby facilitating the formation of intricate shapes and geometries that can be customized to meet specific automotive requirements. This flexibility allows for the seamless integration of FRP profiles into numerous automotive components, including body panels, structural supports, interior trims, and suspension parts. Additionally, FRP pultrusion profiles demonstrate high fatigue resistance, a crucial aspect for automotive applications that involve repetitive loading and vibrations. The fatigue resistance of FRP profiles guarantees their enduring performance and aids in averting failures and breakdowns. Lastly, FRP pultrusion profiles are non-conductive, an advantageous attribute in automotive applications necessitating electrical isolation. This property obviates the necessity for supplementary insulation and mitigates the risk of electrical failures and short circuits. All in all, the amalgamation of lightweightness, robustness, corrosion resistance, design flexibility, fatigue resistance, and electrical non-conductivity renders FRP pultrusion profiles suitable for diverse automotive applications, thereby contributing to enhanced performance, fuel efficiency, durability, and safety within the automotive industry.

- Q:Can FRP pultrusion profiles be used in the water treatment industry?

- Indeed, the water treatment industry can make use of FRP pultrusion profiles. These profiles, made of Fiber Reinforced Polymer, are widely recognized for their exceptional resistance to corrosion, impressive strength, and long-lasting durability. These qualities render them highly appropriate for a diverse range of applications within the water treatment field. In particular, FRP pultrusion profiles can be employed in the construction of water treatment tanks, pipes, and other crucial infrastructure. They exhibit remarkable resistance to chemicals, including those commonly employed in water treatment procedures. This resistance to corrosion ensures that equipment enjoys an extended lifespan and maintenance costs are minimized. Moreover, FRP pultrusion profiles boast an impressive strength-to-weight ratio, making them an ideal choice for applications that necessitate lightweight yet robust materials. This quality facilitates the easier installation and transportation of water treatment equipment. Furthermore, the flexibility in design offered by FRP pultrusion profiles is worth noting. Such profiles can be manufactured in a wide array of shapes and sizes to cater to specific project requirements. This capability allows for the customization and optimization of water treatment systems, guaranteeing the efficiency and effectiveness of water treatment processes. In summary, FRP pultrusion profiles present themselves as a dependable and cost-effective option for the water treatment industry. Their excellent resistance to corrosion, exceptional strength, and design flexibility make them highly suitable for numerous applications within water treatment systems.

- Q:Are FRP pultrusion profiles resistant to saltwater corrosion?

- Indeed, FRP pultrusion profiles exhibit exceptional resistance to saltwater corrosion. Their corrosion resistance is a significant advantage over traditional materials like steel or aluminum. The combination of reinforcing fibers and resin matrix in FRP profiles endows them with inherent resistance to the corrosive effects of saltwater. FRP profiles consist of a blend of glass or carbon fibers that are embedded in a thermosetting resin. These constituents do not chemically react with saltwater, effectively preventing the corrosion commonly observed in metals exposed to saltwater for prolonged periods. Additionally, the resin matrix utilized in FRP profiles acts as a protective barrier, further impeding saltwater from reaching the reinforcing fibers. The corrosion resistance of FRP pultrusion profiles renders them exceptionally suitable for applications in marine settings. Seawalls, dock fenders, offshore platforms, and marine vessels frequently employ FRP profiles due to their durability in saltwater environments. This durability guarantees long-term performance and minimizes the necessity for frequent maintenance or replacement. However, it is crucial to acknowledge that although FRP pultrusion profiles demonstrate high resistance to saltwater corrosion, they can still be influenced by other factors like UV radiation or chemical exposure. Consequently, it is vital to consider the precise environmental conditions and consult manufacturers or experts to select the most appropriate FRP profile for a given application.

- Q:Can FRP pultrusion profiles be used in the construction of theme park rides?

- Yes, FRP pultrusion profiles can be used in the construction of theme park rides. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various structural applications. These profiles can be used to build ride components such as supports, beams, frames, and safety structures, providing a lightweight yet robust solution for theme park rides.

- Q:Are FRP pultrusion profiles resistant to caustic soda?

- FRP pultrusion profiles are generally immune to caustic soda, which is a potent alkaline substance capable of corroding certain materials. However, FRP pultrusion profiles consist of robust fibers (like fiberglass) combined with a resin matrix (such as polyester or epoxy). This composite construction renders them highly resistant to chemicals, including caustic soda. Consequently, FRP pultrusion profiles find extensive application in industries prone to exposure to corrosive substances, such as chemical processing, wastewater treatment, and mining. It is worth noting that the choice of resin in the FRP profiles, along with the concentration and temperature of the caustic soda, can impact the overall level of resistance.

- Q:Are FRP pultrusion profiles resistant to high-pressure or corrosive fluids?

- FRP (Fiber Reinforced Polymer) pultrusion profiles possess a general resistance to high-pressure and corrosive fluids. The combination of reinforcing fibers and the polymer matrix in FRP pultrusion profiles yields exceptional chemical and fluid resistance, including corrosive substances. Often, the corrosion resistance of FRP pultrusions rivals or surpasses that of traditional materials like steel or aluminum. Moreover, FRP pultrusion profiles offer the advantage of withstanding high-pressure applications. The inherent strength and stiffness of reinforcing fibers, such as fiberglass or carbon fiber, combined with the resin matrix, enable FRP pultrusions to handle high-pressure environments without failure or deformation. In addition, FRP pultrusion profiles can be engineered and designed to meet the specific requirements of various fluid environments. Manufacturers have the ability to select the appropriate resin system and reinforcement materials, providing the desired level of resistance to specific corrosive fluids. This customization ensures that FRP pultrusion profiles are tailored to specific applications, guaranteeing long-term durability and performance in high-pressure and corrosive fluid conditions. Nevertheless, it is essential to acknowledge that the resistance of FRP pultrusion profiles to high-pressure or corrosive fluids may differ depending on the resin system, reinforcement materials, and specific chemicals involved. Consequently, it is crucial to consult with the manufacturer or a qualified engineer to determine the suitability of FRP pultrusion profiles for a particular fluid application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GRP Molded Grating for All Kinds Of Waterproof Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords