Corrosion Resistant and Fire Resistant FRP Grating with Modern Shape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

l Corrosion Resistance

l Fire Resistance

l Light Weight & High Strength

l Safety & Anti-slip

l Electrical Insulating

l Aging Resistance

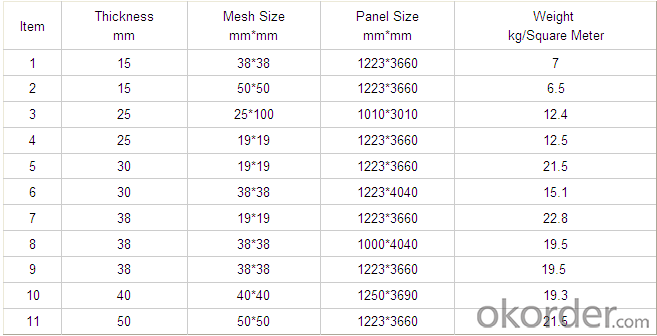

Specification

Advantage

1) coated with prevent aging layer

2) excellent insulating performance

3) no maintenance

4) high strength

5) long service life

6) easy installation

Application

l Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

l In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

l Pool railings in sewage treatment industry

l Corrosive chemical industry equipment around the fence

l All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

PROCESS

FACTORY

- Q:Are FRP pultrusion profiles resistant to chemicals used in food processing?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are highly resistant to chemicals used in food processing. They are specifically engineered to withstand harsh chemical environments, including the cleaning and sterilization agents commonly used in food processing facilities. This resistance makes FRP pultrusion profiles a suitable material choice for various applications in the food industry where chemical resistance is crucial.

- Q:Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Yes, FRP pultrusion profiles can be used in wastewater treatment facilities. FRP (Fiber Reinforced Plastic) pultrusion profiles are known for their high strength, corrosion resistance, and durability, making them suitable for various applications, including in harsh environments like wastewater treatment facilities. These profiles can be used for constructing structures, such as walkways, handrails, grating, and tanks, as well as for reinforcing or replacing traditional materials, such as steel or concrete, in different components of the facility. The corrosion resistance of FRP pultrusion profiles ensures their longevity and reduces maintenance costs, making them a viable option for wastewater treatment facilities.

- Q:Do FRP pultrusion profiles have any limitations or drawbacks?

- Yes, FRP pultrusion profiles do have some limitations and drawbacks. One limitation is their susceptibility to UV degradation, which can cause discoloration and reduced mechanical properties over time if not properly protected. Additionally, FRP pultrusion profiles have relatively low impact resistance compared to materials like steel or aluminum. They may also have limited fire resistance and can melt or burn under high temperatures. Finally, the manufacturing process for FRP pultrusion profiles can be time-consuming and expensive, making it less suitable for small-scale or customized applications.

- Q:Are FRP pultrusion profiles resistant to wear or abrasion?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are highly resistant to wear and abrasion. The combination of the reinforcing fibers, typically glass or carbon, and the plastic resin matrix creates a material that is incredibly durable and can withstand heavy usage. The pultrusion process also ensures a homogeneous structure with fibers evenly distributed throughout the profile, further enhancing its resistance to wear and abrasion. Additionally, FRP pultrusion profiles can be engineered with specific additives or surface treatments to further enhance their resistance to wear and abrasion, making them suitable for a wide range of applications in various industries, such as construction, transportation, and marine.

- Q:What are the different surface finishes available for FRP pultrusion profiles?

- There are several different surface finishes available for FRP (Fiber Reinforced Polymer) pultrusion profiles. These finishes are designed to enhance the aesthetics, durability, and functionality of the profiles. 1. Smooth Finish: This is the most basic surface finish option, where the profile has a smooth and glossy surface. It provides a clean and polished appearance, making it suitable for applications where a sleek and professional look is desired. 2. Textured Finish: Textured finishes add a tactile element to the profile surface, providing increased grip and slip resistance. This type of finish is commonly used in applications where enhanced traction is required, such as walkways, stairs, and ramps. 3. Anti-Skid Finish: Similar to textured finish, anti-skid finishes offer superior slip resistance. They are particularly suitable for areas exposed to wet or slippery conditions, such as marine environments, bridges, and industrial flooring. 4. UV Resistant Finish: FRP pultrusion profiles exposed to outdoor environments are often coated with a UV resistant finish. This type of finish protects the profiles from the damaging effects of sunlight, preventing color fading, degradation, and loss of mechanical properties. 5. Fire Retardant Finish: Fire retardant finishes are used to improve the fire resistance of FRP profiles. They are often required in applications where fire safety is a concern, such as building construction, transportation, and electrical enclosures. 6. Colored Finish: FRP pultrusion profiles can be manufactured with colored finishes to match specific design or branding requirements. This option allows for customization and visual integration with the surrounding environment. It is important to note that the availability of these surface finishes may vary depending on the manufacturer and specific product. Consulting with a FRP pultrusion specialist or supplier can provide more detailed information on the available finishes and their suitability for different applications.

- Q:Are FRP pultrusion profiles resistant to electromagnetic interference?

- Yes, FRP pultrusion profiles are generally resistant to electromagnetic interference. The non-conductive nature of the fiberglass reinforced polymer (FRP) material provides insulation against electromagnetic fields, making them less susceptible to interference. However, the specific level of resistance may depend on the design and composition of the FRP profiles.

- Q:Are FRP pultrusion profiles resistant to electrical arcing?

- FRP pultrusion profiles are generally resistant to electrical arcing. This is because they are made from non-conductive materials like fiberglass reinforced plastic. These profiles do not conduct electricity, which makes them ideal for applications where electrical arcing or conductivity is a concern. However, it is important to note that the specific resistance to electrical arcing may vary depending on the specific composition and design of the FRP pultrusion profiles. It is recommended to consult with the manufacturer or supplier of the profiles to ensure they meet the required electrical resistance standards for a particular application.

- Q:Can FRP pultrusion profiles be used in agricultural structures?

- Yes, FRP pultrusion profiles can certainly be used in agricultural structures. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various applications in the agricultural industry. These profiles can be used in structures like greenhouse frames, livestock enclosures, support beams, fencing, and other agricultural infrastructure.

- Q:Can FRP pultrusion profiles be used in the construction of highway guardrails?

- Highway guardrails can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess several advantages that render them appropriate for this purpose. To begin with, FRP pultrusion profiles combine strength with a lightweight nature, making them ideal for highway guardrails. Their high strength-to-weight ratio enables them to provide the necessary structural support while being significantly lighter than conventional materials such as steel. This facilitates easier and more cost-effective transportation, installation, and maintenance. Moreover, FRP pultrusion profiles exhibit corrosion resistance, unlike steel, which is susceptible to rusting over time due to exposure to harsh weather conditions. The absence of corrosion in FRP guardrails ensures their durability and longevity, thereby reducing the frequency of repairs or replacements. In addition, FRP pultrusion profiles are non-conductive, meaning they do not conduct electricity. This feature is crucial for highway guardrails as it eliminates the risk of electrical shock in the event of accidents involving power lines or lightning strikes. Furthermore, FRP pultrusion profiles can be manufactured in various shapes and sizes to meet the specific requirements of highway guardrails. They can be designed to possess the necessary stiffness and impact resistance to withstand the forces exerted by vehicles during accidents or collisions. In conclusion, FRP pultrusion profiles offer a suitable material for constructing highway guardrails due to their lightweight, corrosion-resistant, non-conductive, and customizable properties. They provide a cost-effective and durable solution that contributes to enhancing safety on highways.

- Q:Can FRP pultrusion profiles be used in the construction industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction industry. FRP pultruded profiles offer several advantages that make them suitable for various construction applications. Firstly, FRP pultrusion profiles are lightweight yet exceptionally strong. This makes them an excellent choice for construction projects as they provide high strength-to-weight ratio, reducing the overall weight of the structure while maintaining structural integrity. This can be particularly advantageous in applications such as bridges, walkways, and platforms. Secondly, FRP pultrusion profiles are highly corrosion resistant. Unlike traditional construction materials like steel or wood, FRP does not rust, rot, or corrode when exposed to harsh environmental conditions, chemicals, or moisture. This makes FRP profiles ideal for outdoor or marine applications where corrosion is a concern, such as seawalls, docks, or offshore structures. Additionally, FRP pultrusion profiles have excellent electrical and thermal insulation properties. This makes them suitable for applications where electrical conductivity needs to be minimized, such as electrical enclosures or cable trays. FRP profiles also have low thermal conductivity, which can help improve energy efficiency in buildings by reducing heat transfer. Furthermore, FRP pultrusion profiles are highly durable and require minimal maintenance. They have a long service life and do not require regular painting, sealing, or treatment like traditional materials. This can result in significant cost savings over the life cycle of a construction project. Lastly, FRP pultrusion profiles can be designed to meet specific strength, stiffness, and dimensional requirements. They can be manufactured in various shapes, sizes, and colors, allowing for flexibility in design and customization. This versatility makes FRP profiles suitable for a wide range of construction applications, including beams, columns, gratings, handrails, and structural components. In summary, FRP pultrusion profiles are a viable option for the construction industry due to their lightweight, high strength, corrosion resistance, electrical and thermal insulation properties, durability, low maintenance requirements, and design flexibility.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corrosion Resistant and Fire Resistant FRP Grating with Modern Shape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords