High Purity White Fused Corundum for Grinding Weels

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

white fused corundum

1.professional manufacture

2.abrasive raw mateirials for grinding whehels

3.free samples are gurantee

Packaging & DeliveryPackaging

Details:a. in 25kg plastic woven bags.

b. In 1000kg big bag.

c. 40 x 25kg plastic woven bags in one big bag.

d. 40 x 25kg plastic woven bags on pallet.

e. 40 x 25kg paper bags on pallet.

Delivery Detail:15days after received the ordet

white fused corundum for grinding wheels

White Fused alumina is smeltin in aelectrical arc furnace from aluminum oxide powder.The colour is white,the hardness and toughtness is a little higher than brown aluminum oxide.

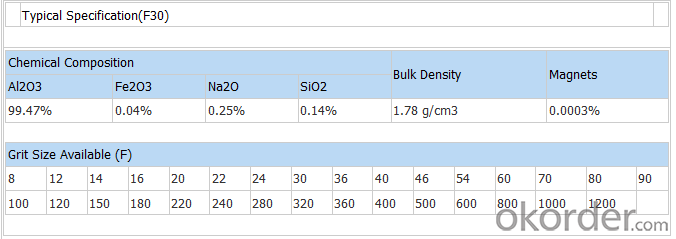

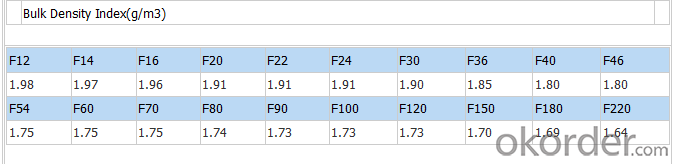

TYPE WAE-17M

This kind of white fused aluminium oxide grain has sharp shape and medium bulk density, can be used for different grinding abrasives applications.

Size Distribution:According to FEPA-Standard 42-1984 R 1993.

- Q:How to choose construction external wall thermal insulation and fireproofing materials?

- Now external wall insulation decoration one board is more popular thermal insulation material. Low-carbon energy-saving insulation decoration board combine two constructions (decoration, insulation) into one, saving nearly ten processes,and construction period. Compared with conventional thermal insulation methods, it can increase construction efficiency one time by shortening 60% of the construction period. It integrates low carbon, energy conservation, decoration, fireproof and building aesthetic effect by combining like-dissolving-like binding system installation and bump fixed system, and under long-term cooperation of air handling system and waterproof system. It has excellent outdoor weather resistance, colour?retention, alkali?resistance, water resistance, scrubbing resistance, crack resistance and temperature change resistance, wear resistance, collion resistance and the paint film is firm and durable, with strong adhesive force and mould proof effect. It can provide all-dimensional thermal insulation, decoration, low carbon and energy conservation and fire prevention for construction projects.

- Q:What are the filling refractories in door leaf of class A fire resistant door?

- Most manufacturers use perlite board. The price is appropriate.

- Q:Which one is better, fire-resistant wood or steel?

- Rebar would weaken and quickly collapse in the fire, and the fire resistance of a heavy log is much better than steel. In many ways, the fire resistance of a large log is equal to reinforced concrete. The heat transfer capacity of wood is 400 times smaller than steel, 8.5 times smaller than concrete. When burning, wood will form a layer of carbon in the surface, and as long as the cross-section of the timber is over a certain size, this layer of carbon it will become an excellent flame retardant layer to protect the interior of the wood from burning. So the United States and Japan and other European countries allow and encourage the use of wood structure with a large section (beam column of 8 inches or more) to construct public buildings without the need for fire treatment applied to wood surface. I hope my answer will be helpful to you.

- Q:What is molten silicon? What refractoriness do refractories made by it have? What properties of using does it have?

- Molten silicon can be called quartz glass, which shows an amorphous silicon state. It is a liquid fusion at above 1723 degree and is an ultra-cooling state at low temperatures. It is not generated in refractories, but generated in the matrix, showing liquid state at a high temperature capable of buffering the stress with somewhat binding properties. If quartz glass is used as refractory, its function are melrly these ones. (These are what I konw for reference only.)

- Q:What kind of material is refractory bauxite?

- Bauxite, also known as bauxite alumina or bauxite with high alumina, is the main raw material for the production of high alumina (aluminum content ≥48%, belongs to LAS) refractory. It must be calcined bauxite ore.

- Q:As for fireproofing material rock wool and glass wool, which one is better?

- First of all, glass wool and rock wool fireproof materials, rock wool and glass wool belong to Class A fireproofing rating, secondly, rock wool can endure high temperature of 800 degrees, glass wool high temperature of 450 degrees, again,unit weight of rock wool is relatively heavier and unit weight of glass wool is lighter, finally, glass wool has better waterproof performance.

- Q:what are the requirements of fireproofing material?

- answer: 1 fireproof materials are used in construction, in various forms and it has played an absolute role in modern fireproofing, common fireproofing materials include fireproof?panel, fire door, fireproofing glass, fire?retardant?coating, fireproof bag,etc. 2, fireproof?panel is the most common texture in the market. There are two common types: One is the high pressure decorating refractory slab, it's advantages are fireproofing,moisture-proof, wear-resistant, oil resistant, easy to clean, and it has various colors; another one is glass magnesium fireproof board, external layer is decoration materials, and inner layer is mineral magnesium fireproofing material, and it can endure 1500 degrees high temperature but has bad decoration. Installing fireproof suspended?ceiling in outlet channel of construction, stairwell and corridor can ensure safe evacuation of people and protect people from attacking of fire spreading in the disaster. 3, the production process of fire and moth proof wood: firstly, put general wooden materials into solution with calcium, aluminum and other cations, then soak it into solution with phosphate radical, silicate and other anions. Thus, the two ions will be carried out chemical reaction in the wood, forming a ceramic-like material, and intimately fill the voids of cells, so that the wood has the fireproofing and mothproof properties.

- Q:Is there requirement for radiation indicator in refractory?

- All refractories have no radiated harm to environment, so there is no requirement. From the elemental analysis, magnesite. I do not know it is helpful to you. But for refractory rwa material, any chemical element is radiated, including silicon?dioxide; If they are radioactive. From the use analysis, such as bauxite, do not have use value.

- Q:Which brand of thermal insulating refractory is good?

- Brands of thermal insulating refractory: 1, Armaflex(German brand). Manufacturer: Armacell thermal insulation materials (Guangzhou) Co., Ltd, Armacell thermal insulation materials (Suzhou) Co., Ltd. 2, Durkflex (American brand) Manufacturer: Durkee (Guangzhou) thermal?insulation?material Co., Ltd. Durkee (Wuhan) thermal?insulation?material Co., Ltd. 3, Aeroflex (Thailand Brand) Manufacturer: Aeroflex Polymer Technology (Shanghai) Co., Ltd.

- Q:Is fireclay corrosive?

- No. All of the refractory materials have stable chemical properties and their usability can be guaranteed under high temperatures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Purity White Fused Corundum for Grinding Weels

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords