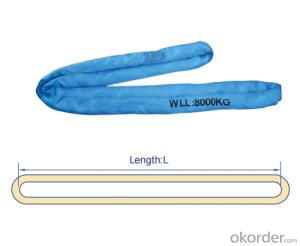

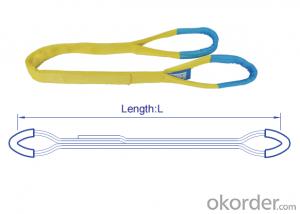

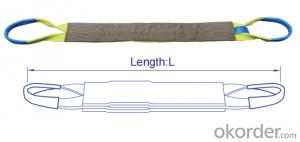

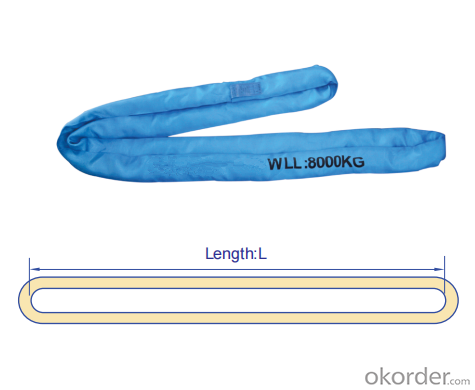

Heavy Duty Soft Round Lifting Endless type Textile Sling/Webbing Sling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Heavy Duty Soft Round Lifting Endless type Textile Sling/Webbing Sling

Chracteristics:

Soft, light, no harm to the cargo, safety, long life and so on.

Light and soft, can be used in small narrow space.In PU processing, anti-abrasion is enhanced,Non-conductive, no danger of electric stroke.

Product usage :

Apply to oil pipelines, large diameter thin-walled pipe and products hoisting.

Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, erospace and other fields.

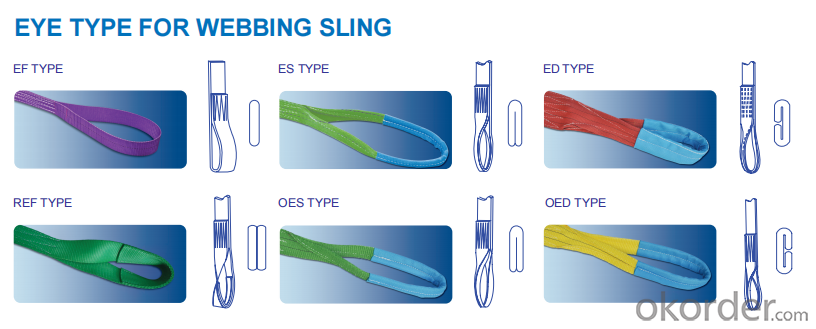

More Type:

Company Profile:

We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

Shipping:

1.Selling Units:Single item

2.Single package size: 30X4X5 cm

3.Single gross weight:5 kg

4.Package Type:Shrink-packaging + Carton Box + Pallet

Certificate:

- Q:What are the installation steps for crane beams?

- The crane beam and track shall be corrected after the main component is fixed. Fix immediately after correction, in order of fixation, bolt first and then weld.

- Q:What are the specifications for the length, length, and method of operation of the wire rope?

- The use of wire rope in the atmospheric environment, mainly caused by the failure of wire rope is fretting fatigue, at present, the wire rope for the first time in the field of fretting fatigue control measures is the phosphating coating steel wire rope patent technology production, steel wire after manganese phosphating or zinc manganese treatment, wear resistance, enhance the surface of steel wire that is not easy to wear and corrosion resistance of the fatigue life is greatly improved

- Q:20 tons sling rope, steel wire or chain?

- The strength of the steel wire rope can reach 2000-2500MPa, and is made by using cold drawn steel wire. The tensile strength is much higher than that of the chain, so that the weight of the sling can be reduced, the production efficiency can be higher, and the steel wire rope is preferred.

- Q:Does the pressing rope have any influence on the tension value of the wire rope?

- According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

- Q:Why are the suspension bridges a main cable, even a n multi sling, not a bridge directly from the tower?

- Finally, the gravity of the main beam becomes the two vertical force of the tower, so that the force passes to the pier under the tower.There are more cables, and the same reason. There are a lot of bars, that's to distract the main girder from the cables.As a kind of cable of cable-stayed bridge, more than beam bridge spanning capacity is the main bridge of long span bridges. The cable stayed bridge is composed of many cables which are directly connected to the tower. The cable-stayed bridge is composed of pylon, main beam and stay cable. The types of pylon are A, inverted Y, H and single column. The materials are steel and concrete. There are single cable plane, parallel double cable plane and inclined cable plane in the stay cable. The first modern cable-stayed bridge was built in Sweden in 1955 and has a span of 182 meters. At present, the largest span cable-stayed bridge built in the world is the Normandy bridge in France, with a main span of 856 meters. The Shanghai Yangpu bridge, built in 1993, is the largest cable-stayed bridge in China, with a main span of 602 meters

- Q:What are the selection principles for lifting cranes?

- It can adapt to the conditions of road, hoisting, plane layout and equipment, machines and tools, and give full play to its technical performance.

- Q:The wire rope lock can hang a lot of things

- The crane used in atmospheric environment, preferably manganese phosphide coating, steel wire rope, heavy corrosive environment, preferred hot-dip galvanized double phosphating steel wire rope, priority wire rope in sea water. Please note that at the time of purchase, in the purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope or 316 stainless steel wire rope, to protect their legitimate rights and interests, in addition, patent products are generally in the rope on the outer packing of a patent spraying label, warranty should be the main technical indicators, such as the type of phosphating film and film, for reference

- Q:How much is the crane arm of the tower from the residential building recently?

- (1) the drivers and signaling personnel of the tower cranes must be specially trained and issued certificates by the relevant departments, and attention should be paid to whether the type of tower used by the driver is consistent with the actual tower type.(2) special person special plane management, Captain responsibility system, and strict shift shift system.(3) the newly installed or repaired tower crane must perform the machine test operation according to the specifications.(4) tower crane should keep a safe distance from overhead transmission lines.(5) driver's room should be equipped with fire extinguishing equipment.

- Q:They are used for slings, ropes, chains, suspenders, hand hoists, right?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope.

- Q:What are the precautions for rigging in hoisting works?

- 1. develop good hoisting habits and plan how to hang, lift and unload before lifting.2. prepare: determine the weight of the hanging object and its center of gravity, read the attached document carefully, mark the lifting point and weight data. Only when the center of gravity has been determined can the hook be hung at the right place!3. the crane operator shall be informed of the weight of the suspended object.4. the crane hook shall be hung vertically above the center of gravity of the suspended object.5. lifting heavy pieces, both to avoid damage to lifting objects, but also to prevent damage to the rigging itself. The following conditions shall be observed in order to avoid rotation or fall:(a) single leg rigging, the lifting point shall be perpendicular to the center of gravity of the lifting object.(b) if it is a two leg rigging, the suspension point shall be on either side of the lifting object, with the lifting point above the center of gravity.(c) if it is a three leg and four leg rigging, the suspension point shall be evenly located at the center of gravity of the lifting object, and above the center of gravity of the suspended object.Attention must be paid to the lifting angle, between the vertical and the leg): the greater the lifting angle, the smaller the lifting capacity. Lifting angles of more than 60 degrees are absolutely not allowed!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heavy Duty Soft Round Lifting Endless type Textile Sling/Webbing Sling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products