High Tensile Strength PP Nonwoven Geotextile for Cilvil Engineering Project Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of PP Nonwoven Geotextile

CMAX polypropylene non woven geotextile is made from high strength polypropylene short fiber by non woven needle punched manufacturing process. It has separation, filtration, drainage, reinforcement, protection and maintenance etc. function.

Specifications of PP Nonwoven Geotextile

Weight: 100gsm – 1200gsm;

Material:PP, PET

Width: 1m – 6m; Length: as clients’ required

Color: black, white

Technical Data Sheet of PP Nonwoven Geotextile

Item | Unit | Index | ||||||||

Weight per Square Meter | g/m2 | 100 | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | |

Grab | MD | N | ≥350 | ≥700 | ≥1100 | ≥1400 | ≥1800 | ≥2200 | ≥2800 | ≥3400 |

CD | ≥350 | ≥700 | ≥1100 | ≥1400 | ≥1800 | ≥2200 | ≥2800 | ≥3400 | ||

Elongation | MD | % | 50~90 | 50~100 | ||||||

CD | 50~90 | 50~100 | ||||||||

Trapezoidal Tearing Strength | MD | N | ≥135 | ≥280 | ≥350 | ≥400 | ≥480 | ≥550 | ≥650 | ≥750 |

CD | ≥135 | ≥280 | ≥350 | ≥400 | ≥480 | ≥550 | ≥650 | ≥750 | ||

CBR Mullen Burst Strength KN | KN | ≥1.0 | ≥2.1 | ≥3.2 | ≥3.8 | ≥4.5 | ≥5.5 | ≥6.5 | ≥7.5 | |

Tearing Strength | MD | KN | ≥3.5 | ≥8 | ≥12 | ≥18 | ≥24 | ≥30 | ≥40 | ≥50 |

CD | ≥3.5 | ≥8 | ≥12 | ≥18 | ≥24 | ≥30 | ≥40 | ≥50 | ||

Break Strength | MD | % | 40~65 | 50~80 | ||||||

CD | 40~65 | 50~80 | ||||||||

Puncturing Strength | N | ≥180 | ≥360 | ≥550 | ≥750 | ≥900 | ≥1150 | ≥1450 | ≥2000 | |

Peeling Strength | N/5 cm | ≥80 | ≥100 | |||||||

Antiacid alkali-resistant | % | ≥90% | ||||||||

Seive Size O90 | Mm | ≤0.1 | ||||||||

Vertical Permeability | Cm/s | ≤0.2 | ||||||||

Property of PP Nonwoven Geotextile

1).The mechanical values are 2-3 times more than ordinary products.

2).Good acid and alkali resistance, excellent hot melting adhesiveness, high anti-abrasion performance.

Application of PP Nonwoven Geotextile

1) Filtration of soils in drainage applications by retaining soil particles while allowing for the free flow of water.

2) Separation and stabilization in road and railway constructions.

3) Prevention of soil movement in erosion control measures.

4) Cushioning and protection in many containment projects.

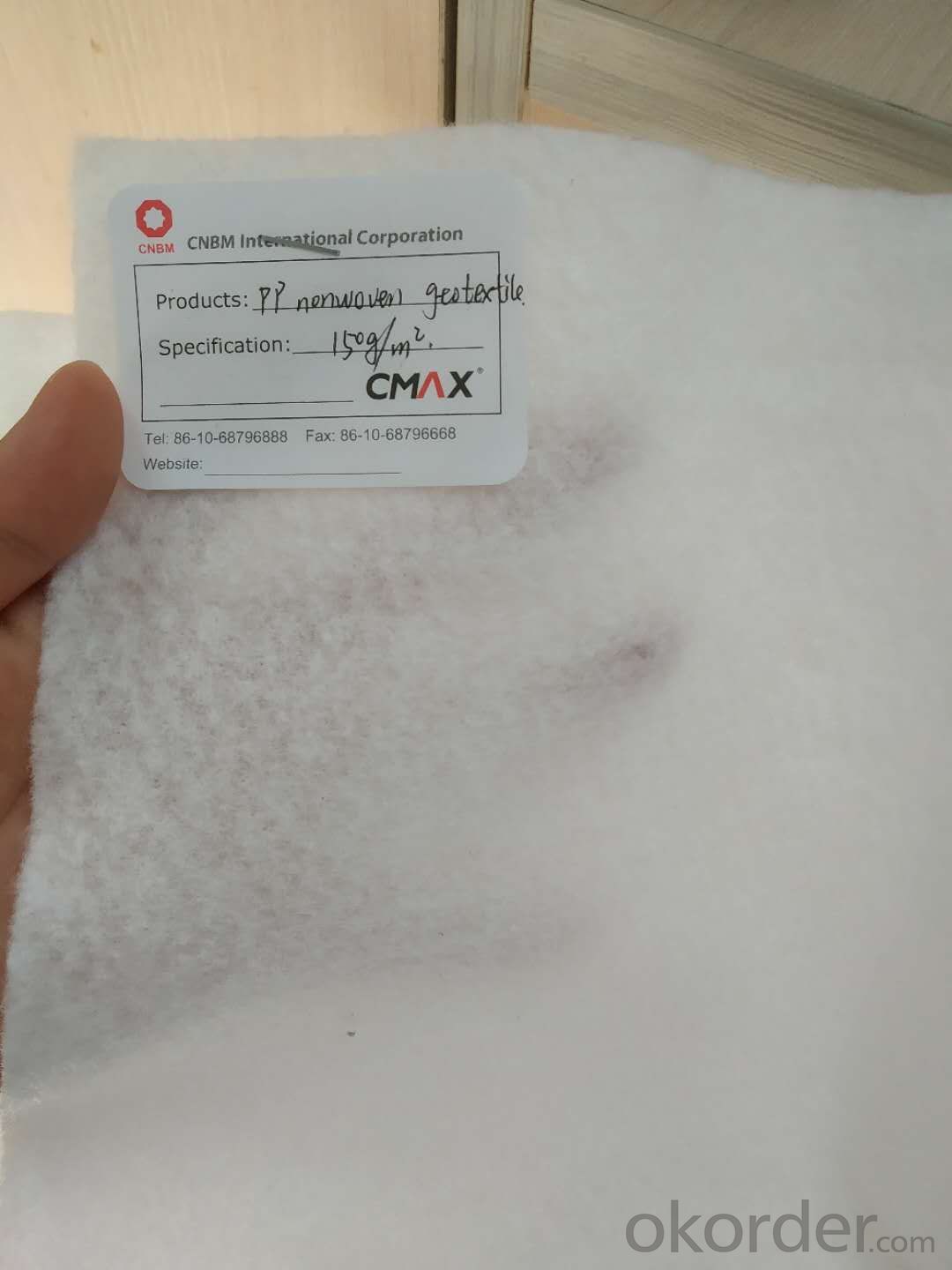

Product photos:

FAQ

1. How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 3 weeks.

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

5. Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6. Can you tell me your main customers?

That's our customers' privacy, we should protect their information. At the same time, please rest assured that your information is also safe here.

- Q:How do geotextiles aid in the reduction of seepage flow?

- Geotextiles aid in the reduction of seepage flow by acting as a barrier that allows the passage of water while preventing the movement of fine particles. This prevents the migration of soil particles and helps to stabilize the soil, reducing the potential for seepage flow.

- Q:Health geotextile how much money ah?

- Health geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. The price according to the weight and standard to set, weight (80-1500g / ㎡), the quality standard is a requirement, divided into non-standard, whitening A, Sinochem, the general national standard, Paul national standard, Wait. Ton price is generally between 4900-7500 yuan / ton, but the weight <200g, an increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan / ton. 187 & lt; 6600 & lt; 5604

- Q:are they used for same purpose with just different terminology?

- Geotextiles And Geomembranes

- Q:How do geotextiles improve the performance of geogrids?

- Geotextiles improve the performance of geogrids by providing additional reinforcement and stability. They act as a separation layer, preventing soil particles from migrating through the geogrids and reducing the potential for clogging. Geotextiles also enhance the drainage capacity of geogrids by allowing water to flow freely through the system, preventing the accumulation of water and reducing the risk of soil erosion. Moreover, geotextiles can increase the overall strength and load-bearing capacity of geogrids, making them more efficient in stabilizing soil and improving the overall performance of geogrid applications.

- Q:Textile geotextile lap length how much

- Lap width is generally 10-15cm

- Q:Geotextile wholesale price of how much money, geotextile fabric manufacturers latest offer

- Geotextile wholesale, ranging from 5000-9000 yuan a ton. Geotextile manufacturers to answer your questions

- Q:Filament spunbond nonwoven geotextile performance requirements for what is the basic item

- Filament spunbond acupuncture non-woven geotextile is the implementation of the national standard GB / T-2008 standard. GB / T-2008 standard for filament spunbond acupuncture non-woven geotextile performance requirements of the basic items include: product vertical and horizontal nominal fracture strength (KN / m), vertical and horizontal nominal elongation at break (%) (KN), vertical and horizontal tearing strength (KN), mass per unit area deviation (%), width deviation (%), thickness (mm), vertical permeability coefficient (cm / s), equivalent pore size (O90 (95) / mm). Only the above indicators meet the corresponding GB / T-2008 standard requirements, be considered qualified filament spunbonded non-woven geotextile.

- Q:Road with a geotextile cloth is a cloth or non-woven fabrics

- Geotextile is a non-woven category, geomembrane is divided into light film, and a cloth a film, two cloth a film, two cloth is a film in the middle of the membrane, both sides of the geotextile composite products. Huazhi geotextile material manufacturers

- Q:Can geotextiles be used in erosion control in river channel stabilization?

- Yes, geotextiles can be used in erosion control in river channel stabilization. Geotextiles are commonly used as a protective layer to prevent erosion and stabilize riverbanks. They are effective in reducing soil erosion, controlling sediment movement, and promoting vegetation growth, making them an ideal choice for erosion control in river channel stabilization projects.

- Q:How do geotextiles help with erosion control on coastal cliffs?

- Geotextiles help with erosion control on coastal cliffs by providing a protective layer that stabilizes the soil and prevents it from eroding. The geotextiles act as a barrier, allowing water to flow through while retaining the soil particles. This helps to reduce the impact of wave energy and prevents the cliff face from eroding.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Tensile Strength PP Nonwoven Geotextile for Cilvil Engineering Project Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords