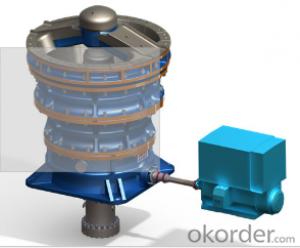

Gyratory crusher used on mining, metallury and cement plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 0.2 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Gyratory crushers are main equipments for coarse crushing ores and rocks in mining, forging, constructing, chemical industry and power stations. They have high crushing rate, high output rate and their products have even grains.

NHI produces three series of gyratory crushers. They are PXZ(heavy), PXQ(light), PXF(introduced). PXZ series is used for crushing material of high or intermediate hardness and PXQ series is used for crushing material of intermediate or low hardness.PXF is mainly used as coarse crushing equipments for large open mines and ore dressing plants.

NHI is the birth place of Chinese first gyratory crusher and the professional manufacturer for designing, testing and manufacturing of gyratory crusher, which has more than 60 years history. These products are welcomed by customers for their variety of models, advanced design, reliable capacity, stable running and low consumption of energy.

In 1987, PXQ1200 gyratory crusher that developed and manufactured by our company won the third prize of National Science and Technology Progress Award. In 1994, PXZ1417 gyratory crusher that developed and manufactured by our company won the third prize of National Science and Technology Progress Award.

- Q:What about shock and blockage in hammer crusher?

- 1, hammer broken, the rotor imbalance;2. The pin becomes bent and broken;3, replace the hammer head or because of cone wear, make the rotor static balance is not required;4, triangle or disc cracks;5, anchor bolts loose.

- Q:I want to buy a mascara. I don't want clumps. Also, I only have $8 (Canadian). I need the info: Price in Canadian $$, your opinion, and if it is natural enough for middle school/7th grade?

- I don't know the price for Canada. But I'm in 7th grade and clump crusher is one of my favorites!! :D it's perfect for our age

- Q:can u get hit by lightning if ur living inside a tall buillding?

- I would not do it –?you are creating too many risks for something to go very wrong. Presumably you will also be grinding to clean up the surfaces and get a clean contact too (even more opportunity for injury and disaster). At the very least run the bike with the fuel tank removed until it stops to drain the carbs (if you cannot locate the drains under the float bowl). Removing/replacing carbs is not difficult – why risk your bike going up in smoke?

- Q:What is the name of the song that has the lyrics go fat boy go fat boy go??

- Bone Crusher ~ Fat Man Stomp

- Q:Remember the set Rise of the Eldrazi? Well, I have a card from that set named Ulamog's Crusher. It is an 8/8 with annihilator 2 and attacks each turn. This card is a common. It can dominate. Do you think that this cards should be at least an uncommon? Thanks for feedback!

- Not really. Ultimately, the rarity only has an influence on the price of the card by limiting supply. It's not really a major consideration to the power of the card. And Umalog's Crusher really isn't that good. It's an 8 mana card that has no impact until your next turn and no defenses (completely vulnerable to things like Day of Judgment and Doom Blade), making it wholely unimpressive compared to something like Primeval Titan or even Artisan of Kozilek, which have major impacts on the game as soon as they hit the field.

- Q:When in August is this atom-crusher suppose to be turned on....if you can send me a reference as well...thanks

- Heres okorder / I doubt this timer is actually counting down to when they press the big red start button and is really counting down to midnight before the day it is supposed to go online.

- Q:they ruin freaking dreams, guys!!!Why does everything done in life to them have to be realistic? What is wrong with having dreams?

- Maybe because theirs we're shot. Don't let anyone get you down. Keep dreaming :-)

- Q:My son is 7yrs old he just moved down here 2 live w/me.My ex said that he has a problem so i stop my son from drinking after 6:30 p.m. it seemed 2 work but 2 day ago he wet the bed i just have run out of ideals.Please help but no bad remarks please.I know how some of u are but then there are nice people out ther 2 so please any ideals help??Thx mom in need of good help.

- The crusher should be designed to push the sides of the can in before applying the crushing action. A dimpled can will collapse much easier than an intact one. Try one each way to prove it to yourself.

- Q:I am Currently looking at a 4wd cherrokee that is lifted 5 and a half inches, i know what the lifted part means, but not the locked. Aand BTW people, I am not talking about the doors.

- It might not be the exact movement of the skill crusher that's causing the pain, but the weight. Try lowering it by a few lbs and see if that helps. Bicep curls work the triceps a tiny bit, but you can't properly train your triceps doing that move. Try extensions standing up, with a dumbbell in your hands, lift your arms up and bend your elbows at your ear. Lift the dumbbell so your arms are fully extended (don't lock your elbows) and slowly lower down. Or kickbacks get in a squat-like position, and extend your arms behind you (think you're a skiier). Or dips, which don't require any weights. Idk how to properly explain them, but google tricep dips.

- Q:why is the hidden life of God not included in the bible?

- miss proxylist can unblock everything

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gyratory crusher used on mining, metallury and cement plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 0.2 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products