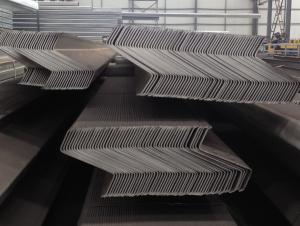

Ground screw piles solar mounting brackets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

ground screw for solar

1.Good corrosion and oxidation resistance.

1.Hot-dipped galvanized steel

2.advanced spiral

The ground screws are installed,using a number of different screwing aids and machines.This screw system is not only suitable for natural ground,but also for dense,and even tarred surfaces. Applications are countless,from securing garden umbrellas,windy dryers and fences;to carports,flag poles and traffic signs.Solar panel systems,advertising boards and even outdoor buildings for events and expositions are quickly and easily erected and removed.

Specification:

Name | Galvanized screw piles |

Dia | 52mm-300mm |

Thickness | 1.75mm-8mm |

Length | 550mm-3500mm |

Material | Steel,ISO 630 Fe360A |

Surface treatment | hot dipped galvanized |

Packing | Pallet |

Delivery Terms | 30-40days |

| Adjustment | 60mm |

| Durchmesser Lochbohrung | 3×M16 |

Easy to install:

The tilted module can be put into the extruded rail in any location and can be highly pre-assembly with the clamp to minimize the time and cost of installation.

High durability:

With all structural components comprised of high class stainless steel and anodized aluminum alloy, it is designed for 15 years service life.

Stand up to extreme weather:

This system is designed to stand up to the extreme weather complied with the AS/NZ1170 and other international structure load standard by the skilled engineer. The main support components have been tested to guarantee its structure and load-carrying capacity.

- Q:Can a solar mounting system be used in areas with limited access to solar blogs?

- Yes, a solar mounting system can still be used in areas with limited access to solar energy. While the availability of solar energy might be limited, the mounting system itself can still be installed in such areas. However, it is important to consider the amount of sunlight available in these areas before deciding on the size and capacity of the solar system.

- Q:Can solar mounting systems be installed on membrane roofs?

- Yes, solar mounting systems can be installed on membrane roofs.

- Q:How does the cost of a solar mounting system compare to the cost of solar panels?

- The cost of a solar mounting system is typically a fraction of the cost of solar panels. While the exact proportion may vary depending on the specific system and installation requirements, solar panels generally represent the majority of the overall cost of a solar energy system.

- Q:Can a solar mounting system be used for solar streetlights or outdoor lighting?

- Yes, a solar mounting system can be used for solar streetlights or outdoor lighting. These mounting systems are designed to securely hold the solar panels in place, allowing for optimal sun exposure to generate electricity. By using a solar mounting system, solar streetlights and outdoor lighting can be easily installed in various locations, ensuring reliable and sustainable illumination without the need for grid connections or additional energy costs.

- Q:What is the most common type of solar mounting system?

- The most common type of solar mounting system is the rooftop mounting system, which is widely used for residential and commercial solar installations.

- Q:Are there any specific requirements for anchoring when using a solar mounting system on a concrete roof?

- Yes, there are specific requirements for anchoring when using a solar mounting system on a concrete roof. The anchor points must be securely attached to the concrete surface using appropriate fasteners such as screws or bolts. The number and spacing of the anchors will depend on the weight and size of the solar panels, as well as the local wind and snow load requirements. It is essential to follow the manufacturer's guidelines and consult a structural engineer to ensure the safety and stability of the solar mounting system on the concrete roof.

- Q:Can a solar mounting system be used in areas with limited access to quality control measures?

- Yes, a solar mounting system can be used in areas with limited access to quality control measures. However, it is important to ensure that the system is properly installed and maintained to minimize any potential risks or issues. Regular inspections and maintenance by qualified professionals are crucial to ensure the system's safety and performance.

- Q:Can solar mounting systems be installed on floating platforms or bodies of water?

- Yes, solar mounting systems can be installed on floating platforms or bodies of water. These specialized systems, known as floating solar or floating photovoltaic (PV) systems, are designed to harness solar energy while being mounted on water bodies such as lakes, reservoirs, and even oceans. They provide an innovative solution for areas with limited land availability and can offer additional benefits like reduced water evaporation and improved energy production due to the cooling effect of water.

- Q:Are there any specific requirements for installing a solar mounting system on an offshore structure?

- Yes, there are specific requirements for installing a solar mounting system on an offshore structure. These requirements include ensuring the mounting system is designed to withstand the harsh marine environment, including corrosion resistance and stability in high winds and waves. Additionally, the system should be designed to minimize the risk of damage or interference with the offshore structure's operations and should comply with any relevant safety regulations and standards.

- Q:Can a solar mounting system be used in areas with community solar programs?

- Yes, a solar mounting system can be used in areas with community solar programs. In fact, community solar programs often involve the installation of solar panels on a shared or centralized system, which requires a reliable and efficient mounting system to securely hold the panels in place. The solar mounting system plays a crucial role in ensuring the stability and optimal performance of the solar panels, making it a necessary component in community solar projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ground screw piles solar mounting brackets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords