Graphite Electrode Manufacturer/Graphiteelectrode for Arc Furnace/Graphite Electrode for Edm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to 700mm. Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

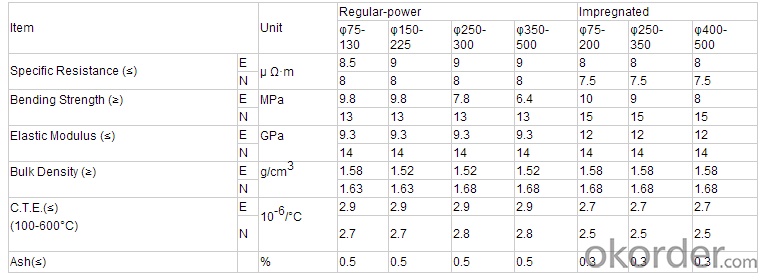

Graphite Electrodes Specifications

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

Technical data:

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:Synthesis techniques of carbon nanotubes

- Catalytic pyrolysis is one of the widely used methods for preparing carbon nanotubes. The method mainly uses transition metal as catalyst, and is suitable for large-scale preparation of carbon nanotubes. The content of carbon nanotubes in the products is higher, but the defects of carbon nanotubes are more.

- Q:The reason why graphite is used as electrode

- Good chemical stabilityGraphite has good chemical stability at room temperature. It can resist acid, alkali and organic solvent.

- Q:Why use platinum ferroalloy instead of iron as electrode?

- Silica (Silica) is widely used in paint, ink, plastic, rubber and cosmetics, are often added to increase the performance of silica, such as oil absorption, extinction, strengthen the mechanical... Etc., and can reduce the cost of...

- Q:What is the striking electrode in the die making? Where is the technical point?

- The electrode in die processing is edm.The discharge produces sparks and forms a "corrosion" to the other pole. The method of machining parts (dies) using this phenomenon is called edm.

- Q:Why is graphite a negative pole and copper is an anode?

- Electrolysis (Electrolysis) is the current through the electrolyte solution or molten electrolyte (also called electrolyte), caused by the redox reaction in the cathode and the anode, the electrochemical cell can occur when an external DC voltage in the electrolysis process.

- Q:Jiqiu conductive graphite electrode, how to compare with copper is relatively large resistance value?

- Look at what kind of graphite electrode you need. Now, the resistivity of ordinary power graphite electrode in our factory is 7.5-8.5. It is not clear that the graphite electrode is dipped in 6--7.3. copper

- Q:What is the difference between SGL graphite electrode and graphite electrode in general?

- Pure graphite is a kind of high-purity graphite. The processing technology of fine graphite and high purity graphite is basically the same, that is, the purity of graphite is different, the purity is higher, and the particle size is basically the same

- Q:How does graphite produce solar cells?

- Gerrit J said: "despite the modifications, but the inherent nature of graphene remains unchanged, is a significant advantage of composite materials."

- Q:Will the concentration of electrolytic sodium sulfite be increased with graphite as electrode?

- Not alwaysIt depends on the rate of electrolyzed water or the rate at which sodium sulfite is oxidized.

- Q:Specification for graphite electrodes commonly used in steel works

- The variety and specifications of graphite electrodes used in modern EAF steelmaking are mainly determined by the technical parameters of the steelmaking furnace. With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Graphite Electrode Manufacturer/Graphiteelectrode for Arc Furnace/Graphite Electrode for Edm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords