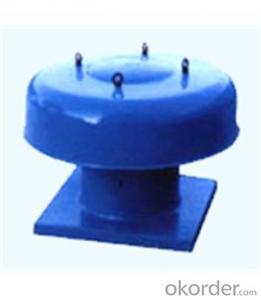

FRP roof fan

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP roof fan is the advanced roof ventilation equipment, mainly used in ventilation hotels, restaurants, theaters, office buildings, laboratories, factories, residential and other buildings.

Roof fan with a beautiful shape, compact structure, high strength, light weight, corrosion resistance, aging resistance, low power consumption, low noise, reliable operation, easy installation and maintenance features, the use of a venturi tube entrance test method test, compared with similar products improve the rate of 30%.

According to user needs, I also can produce the same roof fan explosion model and its performance.

I produced the roof fans, with the following features.

High efficiency, low noise: the use of advanced CAD software, designed by the multi-objective optimization. DWT-Ⅰ series machine numbers 12 # -24 # total of eight machine number fans, by changing the speed, angle and leaf-type approach, the expansion of the range of performance parameters to meet the needs of different use conditions, to the fan with the system area with to facilitate the realization of energy-saving and noise reduction.

Smooth operation and long life: small moment of inertia, high dynamic steady precision, smooth operation, and the enterprise requirements of modern standards of the performance indicators were higher than the fan industry standards to ensure that the fan at the leading position in the peer.

Suitable for a wide range: The fans can use the request, made into explosion proof type, suitable for flammable, explosive and corrosive gas forced air ventilation occasions;

After several provinces and Technical Supervision qualified, users can be assured.

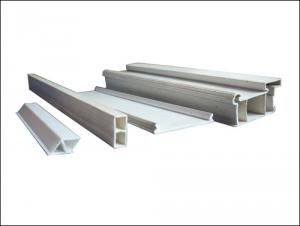

- Q:What is the difference between plastic doors and windows and steel doors and windows?

- PVC plastic doors and windows in the country is widely known as the steel doors and windows, plastic doors and windows is based on polyvinyl chloride (PVC) resin as the main raw material, with a certain percentage of stabilizers, colorants, fillers, impact modifier, Absorbent (shielding agent) and other additives, the extrusion of the material.

- Q:Plastic doors and windows profiles

- The inherent quality of the profile and its reasonable structural design are the prerequisites for the manufacture of high-performance plastic windows. First of all, there must be good formula and high-quality raw materials and advanced production technology to ensure the quality of profiles. In addition from the structure of the profile of a single cavity and multi-cavity PVC plastic profiles, the cavity can be designed ribs, ribs, boss, etc., can be divided into two cavities cavity, three chamber or multi cavity, Can be better from the role of thermal insulation, on the other hand can make the cavity have different purposes, and some used to fix the rigidity of the steel lining, and some used to set the drainage chamber, and some internal ribs can be prevented Profile deformation, the inner ribs can improve the rigidity of the profile, increase the inertia moment of profiles, and improve the impact resistance of profiles.

- Q:The state of high-rise residential building doors and windows materials are not allowed to use steel profiles are expressly provided?

- Plastic can not be used mainly to see its ability to withstand wind pressure can not meet the requirements, and the state did not force the request. At present, only Qinghai is limited to plastic steel, it is because the UV is relatively strong in Qinghai, steel weather resistance is not good aluminum. In fact, as early as ten years ago, steel doors and windows can be used in the tall buildings in Xiamen, indicating the use of absolutely no problem, provided that your doors and windows must be reasonable design, through the local fifty years once the wind. But also in the doors and windows production and installation process to comply with the specification.

- Q:Is not aluminum alloy better than steel?

- Aluminum alloy usually use copper, zinc, manganese, silicon, magnesium and other alloy elements, the early 20th century by the German Alfred Wilm invention, the development of the aircraft to help greatly, after a World War II German aluminum alloy composition is classified as state secrets. Compared with ordinary carbon steel has a lighter and corrosion-resistant performance, but the corrosion resistance is not as pure aluminum. In the clean, dry environment, the surface of aluminum alloy will form a protective oxide layer.

- Q:The difference between steel and aluminum alloy profiles

- Aluminum doors and windows better, but I said that this aluminum alloy is not an ordinary aluminum alloy, its full name is called "heat insulation bridge aluminum" profile. This kind of aluminum alloy doors and windows profiles, it is more complex than ordinary old aluminum alloy structure, thickness and strength and finish much higher than the old aluminum alloy doors and windows profiles, his structural design more scientific and efficient for the family to save energy , With good insulation noise, cold insulation properties, not easy to deformation, discoloration, corrosion resistance and rugged than plastic steel profiles are several times higher. In the decoration of doors and windows, for steel windows and broken bridge aluminum alloy doors and windows of choice, broken bridge aluminum doors and windows of the cost is much higher than the steel doors and windows.

- Q:What is the steel profile?

- The profile is still visible when the window is still visible

- Q:How plastic embossed profiles are made

- Plastic processing is a complex process, generally divided into the following main processing methods:

- Q:Is the powder produced when the crushed plastic is crushed?

- The use of alloy steel blade, long life; the same time, the separation of the design, easy maintenance and cleaning, and a double structure, equipped with sound insulation material, the noise is very low, knife shaft seat after a rigorous balance test, There are four rounds, easy to move.

- Q:Plastic steel window profile material

- GB 8814-2004 according to the thickness of the main section of the profile will be divided into three categories of ABC, according to the "visible wall thickness minimum / non-visible wall thickness minimum" said, A type of wall thickness of 2.8 / 2.5mm, B Type of material requirements wall thickness 2.5 / 2.0mm, C type of wall thickness does not specify the requirements. The mainstream of the national standard profiles are Class B.

- Q:PVC extrusion profiles compared to ABS, PE and other plastic profiles have any advantages?

- ABS weather resistance is poor, the proportion of light, chemical resistance is poor, but if the ABS and PVC blending modified into PVC / ABS alloy pellets, you can combine the advantages of two products in one, the price is cheap, the current price 14500-17000 yuan / ton.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP roof fan

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords