Sintering machine desulfurization dust removing tower

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

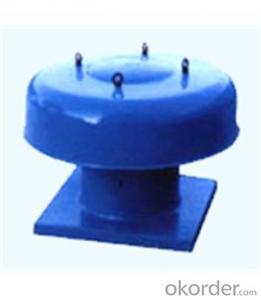

Steel sintering machine desulfurization dust removing tower

Our company specializing in the production of glass steel desulfurization tower, the waste heat of the flue gas desulfurization tower, power plant desulfurization tower, steel desulfurization tower, environmentally friendly desulfurization tower, double alkali method desulfurization tower, water film desulfurization tower, industrial furnace desulfurization tower, sintering furnace desulfurization tower, boiler flue gas desulfurization tower, desulfurizing tower and other environmental protection equipment in Colleges and universities. Welcome the masses of friends to buy!

Steel sintering machine desulfurization and dedusting tower adopts the principle of design and the special manufacturing process, so that the gravity settling, inertia deposition, adsorption, surface force, no plug nozzle jet, dust removal and desulfurization mechanism of acoustic wave and the special structure of the atomization, a multi-channel, desulfurization reaction, and special dehydration demister, the sintering machine desulfurization dust removing tower dust removal efficiency of iron and steel plant high, well repair operation, low cost, stable performance, simple operation. Sintering machine desulfurization dust removing tower special high temperature resistance, wear resistance, corrosion resistance, long service life, fan operation without water. Special opponent burning furnace, boiling furnace, pulverized coal boiler, the unique management effect. So steel sintering machine desulfurization dust removing tower of our company put on the market by the user and the environmental protection departments of praise.

When the draft fan is started, the dust catcher in the air discharged rapidly, at the same time the dust laden gas into the interior of the influence of atmospheric pressure and the flue gas, and reflect the spray washing spray device in the flue gas is fully mixed with water, fine dust particle cohesion and coarse aggregate, in the guide, the high-speed airflow into the barrel of the liquid, thereby to produce a large amount of foam, forming a water film, the dust of flue gas in the water has enough time to capture interactions of dust particles in the flue gas. SO2 in flue gas with strong hydrophilicity, absorption of dust removal and desulfurization effect in alkaline solution. Flue gas purification separation device after removal of water, from the chimney into the air. Sewage can be discharged into the boiler slag removing machine or into the circulating pool, sedimentation, sludge from the addition of discharge slag machine out.

Steel sintering machine desulfurization dust removing tower

Steel sintering machine desulfurization and dedusting tower adopts the principle of design and the special manufacturing process, so that the gravity sedimentation, the inertial deposition, adsorption, surface forces, no plug nozzle jet, dust removal and desulfurization mechanism of acoustic wave and the special structure of the atomization, a multi-channel, desulfurization reaction, and special dehydration demister, the sintering machine desulfurization and dedusting tower steel plant dust removal efficiency is high, operation, low maintenance cost, stable performance, simple operation. Sintering machine desulfurization dust removing tower special high temperature resistance, wear resistance, corrosion resistance, long service life, fan operation without water. Special opponent burning furnace, boiling furnace, pulverized coal boiler, the unique management effect. So steel sintering machine desulfurization dust removing tower of our company put on the market by the user and the environmental protection departments of praise.

When the draft fan is started, the dust catcher in the air discharged rapidly, at the same time the dust laden gas into the interior of the influence of atmospheric pressure and the flue gas, and reflect the spray washing spray device in the flue gas is fully mixed with water, fine dust particle cohesion and coarse aggregate, in the guide, the high-speed airflow into the barrel of the liquid, thereby to produce a large amount of foam, forming a water film, the dust of flue gas in the water has enough time to capture interactions of dust particles in the flue gas. SO2 in flue gas with strong hydrophilicity, absorption of dust removal and desulfurization effect in alkaline solution. Flue gas purification separation device after removal of water, from the chimney into the air. Sewage can be discharged into the boiler slag removing machine or into the circulating pool, sedimentation, sludge from the addition of discharge slag machine out.

- Q:Fence material outside the plastic inside is iron or steel this material called

- Generally refers to steel profiles. Plastic profiles are used for the production of doors and windows with PVC profiles, as early as the late 1950s has been in Germany, China began in 1983 from the beginning of the 20th century, the late 90s began universal application. Because simply use PVC profiles processing doors and windows strength is not enough, usually in the cavity to add steel to enhance the stability of doors and windows, so the profile of the steel interior made of plastic doors and windows are often called steel doors and windows. With the extensive use of steel doors and windows, PVC profiles for the production of steel doors and windows are commonly known as steel profiles.

- Q:Bathroom plastic door with what material to do

- 1 PVC plastic doors and windows 1) In all kinds of building windows, PVC plastic windows in saving energy production profiles, recycling of recycled materials and the use of energy consumption has a prominent advantage in the insulation and energy saving has excellent performance and low cost. 2) In order to increase the rigidity of the window, in the window frame, sash, the tread profile of the force bar, should be based on the strength of the wind pressure design and other requirements to determine what kind of reinforced steel. 3) Coextrusion of UPVC resin with colored polymethyl methacrylate (PMMA) or acrylonitrile-styrene-acrylate copolymer (ASA), as well as coating on white profiles, can be coated with a variety of textures and A variety of surface color decorative effect. In addition, UPVC resin powder is also added to the pigment mixture extrusion of the body dyeing technology. But there are still different views on this technology, it should be particularly careful in the selection, to check the kind of profiles by artificial accelerated aging test after the color changes. It is recommended to coat the color film with the color film to improve its weatherability.

- Q:What is the difference between plastic doors and windows and steel doors and windows?

- PVC plastic doors and windows in the country is widely known as the steel doors and windows, plastic doors and windows is based on polyvinyl chloride (PVC) resin as the main raw material, with a certain percentage of stabilizers, colorants, fillers, impact modifier, Absorbent (shielding agent) and other additives, the extrusion of the material.

- Q:Specification for steel profiles

- That might be a titanium alloy, and now the kitchen is very popular. A lot of wardrobe are used to do that, I have not done. I have 40 steel small profile, you can use screw connection, can also be welded

- Q:The main features of steel profiles

- In the building construction is mainly used for sliding, sliding doors and windows, fence, pipe and ceiling material applications, through the new process is also widely used in automotive engine protection board, not only light weight, and good toughness, with just fine Nature, and sometimes also known as alloy steel.

- Q:What is the steel profile?

- Simply put the profile is installed into a window that can still be seen after the outer surface. Such as the large and small faces of the box. While the middle glass trough installed glass and pressed after the invisible, that is non-visible surface.

- Q:How many meters of a conch plastic steel profile

- Plastic specifications of a lot of steel, do not know what you want to know? But each type of material has a standard weight of rice, their own to know, for example: Conch 60 two-track sliding box weight is 1.22kg, then 1000kg divided by 1.22 = 819 meters

- Q:How to identify the installation of plastic or plastic

- According to the characteristics of profiles, the profiles are roughly divided into European and American two. European doors and windows of its characteristics are: profile formulations still use the traditional lead salt heat stabilizer, a small number of countries and enterprises began to use environmentally friendly organic tin heat stabilizer; main section of the profile profile is generally designed for three or four main chamber, The total number of chambers to 6 to 8, wall thickness is generally 2.5 ~ 3.0mm. Doors and windows with fan-fan frame structure, fan section larger, with pulley, can be removed; built-in glass, dry mosaic; window open in the foreign under the hanging window-based, a small amount of sliding window.

- Q:Is the powder produced when the crushed plastic is crushed?

- 1, plastic shredders and power units to be installed firmly. If you need plastic crusher long-term fixed operation, it should be fixed on the basis of cement; if you need plastic crusher flow operation, the unit should be installed in the angle made of iron on the base, and to ensure that the power machine (diesel or motor) and plastic The pulley groove of the crusher is in the same plane of rotation. 2, after the installation of plastic crusher to check the Department of fasteners fastening, if loose to be given to tighten. Also check the belt tightness is appropriate. 3, plastic shredder before starting, first hand rotation of the rotor, check the claws, hammer and rotor operation is flexible and reliable, broken room with or without collision phenomenon, whether the direction of rotation of the rotor and arrows in the same direction, Plastic crusher lubrication is good. 4, do not casually replace the pulley, to prevent the speed is too high to cause the explosion chamber explosion, or too low speed affect the efficiency of the pulverizer. 5, plastic shredder should be maintained after the first start idle 2 ~ 3min, no abnormal phenomenon after feeding work. 6, the work should always pay attention to the operation of the plastic crusher, first of all, to be uniform to prevent the blockage of waste room; Second, do not work for a long time overload. If you find a vibration, noise, bearing and body temperature is too high, such as spraying out of the phenomenon, should immediately stop checking, troubleshooting can continue to work.

- Q:What is the material of steel

- In the building construction is mainly used for sliding, sliding doors and windows, fence, pipe and ceiling material applications, through the new process is also widely used in automotive engine protection board, not only light weight, and good toughness, with just fine Nature, and sometimes also known as alloy steel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Sintering machine desulfurization dust removing tower

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords