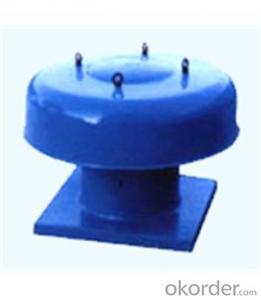

FRP axial fans

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Axial fan is a national committee to promote the use of a mechanical efficiency low-pressure ventilator, the aircraft low power consumption, low noise, and has excellent corrosion resistance and other characteristics. Can be used as industrial plant, machinery manufacturing, chemical industry, printing and dyeing, electroplating, pharmaceutical and other industries; theaters, hotels, office buildings, residential and other buildings. If wind shell removed. Also for their fan, but also in a longer exhaust pipe, installed in series interval, and to increase the total pressure of the pipeline.

(B) Fan Type:

T35-type axial fan impeller diameter divided according to the size NO2.8, NO3.15, NO3.55, NO4, NO4.5, NO5, NO5.6, NO6.3, NO7.1, NO8, NO9, NO10 , NO11.2 thirteen machine number, number of leaves of each machine number are for four. Leaves can be loaded into a 15 °, 20 °, 25 °, 30 °, 35 ° five kinds of angles. Therefore, since the size of each machine number of the blade installation angle, rotating speed of the spindle is different from the fan air pressure, air volume, and power consumption is not the same. (See performance table specific performance)

Transmission: selection of each pole motor with impeller directly coupled, the body shell made of a cylindrical shape, the direction of rotation is clockwise (viewed from the motor direction).

Fan selection table (performance table)

T35-type axial fan performance and choice of performance tables, refers to the standard conditions (temperature of 20, 50% relative humidity, atmospheric pressure 760 mm Hg, gas specific gravity 1.2 kg / m3) of air performance. When the rotor speed is changed, the fan can be converted following formulas:

Axial Fan Maintenance

1, the fan should be carefully checked before installing it because of packaging, transportation and damage, deformation, can be repaired properly after installation. The installation should pay attention to check the availability of loose coupling portion, blade and duct clearance should be uniform, not collide.

2, connecting the outlet of the pipe weight should not be borne by the fan duct, the installation should additional support.

3, in the axial fan air inlet end device must be installed set and installed protective barbed wire.

4, the fan base engaged with the ground plane must naturally not be forced to beat a bolt connection, to prevent deformation of the base. When you install the application level gauge calibration base, padded in order to maintain its horizontal position, and then tighten the bolt facilities.

5, the axial fan hoisting allowed to use, after installing wire transfer must first trial.

6, after a long time fan of unused, re-use, you must first check whether the prison because each coupling portion and reliable, and after the test run before the official use.

7, after the formal operation of the fan, once a year to check for loose screws, wires epidermis is damaged, repaired according to their specific circumstances.

8, always pay attention to the fan is in operation without abnormal noise, vibration is increasing, and timely inspection repair.

- Q:Fence material outside the plastic inside is iron or steel this material called

- Plastic steel profiles are made of polyvinyl chloride (PVC) resin as the main raw material, plus a certain proportion of stabilizers, colorants, fillers, UV absorbers, etc., by extrusion of the profile.

- Q:Plastic doors and windows profiles

- Plastic doors and windows with its good insulation, insulation, sound insulation and corrosion resistance to become steel and wood windows of the alternatives, but because of the market is not mature, raw material prices soared and the price of the profile is soaring, making a lot of profiles manufacturers Not to sacrifice the quality of the material to reduce costs, in the profile by adding a lot of calcium carbonate or the use of low-cost raw materials additives, plastic window with poor quality hardware accessories, ultra-thin ribs plus rough manufacturing process, so low-performance products into After the market, to the user and the industry has brought a great negative impact, the long run, will repeat the sixties and seventies of the same mistakes.

- Q:Plastic steel profiles how to open the mouth of the best illustration and the formula there are cross-port V to answer to a comprehensive ah

- V-shaped mouth, no matter how much your profile, are the width of the atrium divided by 2 plus 3 mm. It's up. Such as the dome width of 5 cm, then the depth of V is 5 cm divided by 2 and then minus 3 mm is the depth of 2.1 can be adjusted

- Q:What belongs to plastic profiles

- Plastic Profile A: Impact modifier Plastic profiles, such as without impact modifier, plastic profiles will be very brittle, slightly collision, easy to break. Plastic profiles used in the production of anti-impact agent modifier mainly by the following three categories: chlorinated polyethylene, polyacrylates, ethylene - vinyl acetate copolymer. Plastic profile additive two: heat stabilizer Plastic profile is a thermosensitive plastic, so in the production and processing of plastic profiles, heat stabilizer is essential. The metal salt in the heat stabilizer absorbs the HCL from the PVC, so it can delay the decomposition rate of the plastic and prolong the decomposition time. The most commonly used in the production of plastic profiles is the compound lead salt, which has high thermal stability and low cost. Plastic profile additives three: lubricant The main role of the lubricant is to reduce the polymer and processing equipment and polymer molecules between the internal friction between the friction caused by excessive heat caused by resin degradation, improve the efficiency of heat stabilizer.

- Q:What is the amount of plastic profiles

- Plastic window frame and sash with lap way to seal, fan and the box part of the overlap called the amount of overlap. The industry standard does not specify the amount of lap. For the flat window, lap is generally between 8 ~ 10mm. If the conditions permit, the amount of lap as much as possible to choose a larger, so that in the installation and use, even if the frame fan overlap position slightly dislocation, but also to ensure that the seal between the frame fan. Using different hardware, but also affect the amount of overlap factors. If the use of ordinary handle, frame fan lap can choose a larger, if the use of transmission handle, frame between the need for a certain gap between the installation of the drive, so the amount of lap would have to be smaller, otherwise, installed on the fan Of the transmission is easy to touch the window frame, affecting the sash switch. Therefore, even with the same profile, the lap should also be determined separately.

- Q:Plastic doors and windows and plastic windows do not like?

- According to the material plastic doors and windows can be divided into PVC plastic doors and windows and glass fiber reinforced plastic (FRP) doors and windows. The following are the same as the " 1, PVC plastic doors and windows 1) In all kinds of building windows, PVC plastic windows in saving energy production profiles, recycling of recycled materials and the use of energy consumption has a prominent advantage in the insulation and energy saving has excellent performance and low cost. The following are the same as the " 2) In order to increase the rigidity of the window, in the window frame, sash, the tread profile of the force bar, should be based on the strength of the wind pressure design and other requirements to determine what kind of reinforced steel. The following are the same as the " 3) Coextrusion of UPVC resin with colored polymethyl methacrylate (PMMA) or acrylonitrile-styrene-acrylate copolymer (ASA), as well as coating on white profiles, can be coated with a variety of textures and A variety of surface color decorative effect. In addition, UPVC resin powder is also added to the pigment mixture extrusion of the body dyeing technology. But there are still different views on this technology, it should be particularly careful in the selection, to check the kind of profiles by artificial accelerated aging test after the color changes. It is recommended to coat the color film with the color film to improve its weatherability.

- Q:The main features of steel profiles

- In the building construction is mainly used for sliding, sliding doors and windows, fence, pipe and ceiling material applications, through the new process is also widely used in automotive engine protection board, not only light weight, and good toughness, with just fine Nature, and sometimes also known as alloy steel.

- Q:Steel windows and aluminum windows compare which is more expensive

- Air tightness: Plastic window due to the box, fan components are welded, so the air tightness should be slightly better than the spiral of the aluminum alloy window, but the aluminum window profile height accuracy, box, fan with more closely, so the two are still in a Level level. 3, the insulation performance: aluminum window insulation performance as plastic window is good, but the ratio of the two window heat transfer ratio is only 1.36 times (single window) and 1.44 times (single frame double glass).

- Q:Is not aluminum alloy better than steel?

- Aluminum alloy usually use copper, zinc, manganese, silicon, magnesium and other alloy elements, the early 20th century by the German Alfred Wilm invention, the development of the aircraft to help greatly, after a World War II German aluminum alloy composition is classified as state secrets. Compared with ordinary carbon steel has a lighter and corrosion-resistant performance, but the corrosion resistance is not as pure aluminum. In the clean, dry environment, the surface of aluminum alloy will form a protective oxide layer.

- Q:Is the powder produced when the crushed plastic is crushed?

- Plastic crusher Plastic crusher refers to the crushing of various plastic and rubber such as plastic profiles, pipes, rods, silk, film, scrap rubber products. Granules can be directly for extrusion, as the production of raw materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP axial fans

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords