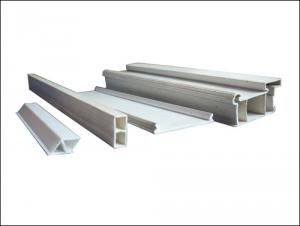

Glass steel pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass steel pipes

To illustrate, a glass steel buried pipeline foam construction

1, direct buried insulation pipe can be widely used in heating, geothermal, refrigeration, municipal construction, oil and other industrial sectors, adding flame retardant protective layer can also be used for overhead pipeline.

2, the depth of burying must ensure that load ten tons truck safety through, as far as possible, reduce heat loss, shall be laid in the ice below the line, different regions should be based on different conditions of the region specific treatment.

3, pipe trench excavation size should guarantee between the tubes, 200-250 mm interval left between the pipe and the trench wall, in order to on-site installation and joint treatment, gully bottom brick soil compaction, when necessary, available sand bedding.

4, direct buried pipe on the road, the laying depth, just not backfill soil covering is made into the trench forms in the pipe bedding, reinforced concrete plate groove or concrete casing treatment.

5, between the pipe and pipe, using welding (glass pipe connection technology and pressure test standards set separately) pipe after installation, pressure test (9 /cm L) 10 minutes buck 0.5 kg /cm - qualified, should maintain the ditch bottom water and installation of pipe welding joint, made after fully cured (48 hours) will be put into the ditch bottom pipeline, so as not to not make joint processing into the ditch, water soaking pipe joint part and reducing waterproof, anti-corrosion, insulation effect.

6, in the process of installation of the insulation pipe, can be installed on one side, the side to do joint processing, can also be installed all pressure test again after the joint processing.

(1) in order to ensure the joint waterproof, anti-corrosion, insulation effect, to ensure that joint site condition is very necessary.

(2) joint field temperature, in the operation should be kept above 10 degrees, the minimum should not lower than 5 DEG C, the winter is not suitable to do joint processing, rainy days, not suitable for joint treatment, gully bottom wet, water does not do joint processing.

Two, direct buried insulation pipe overview:

Direct buried insulation pipe is mainly composed of four parts.

1: according to the requirement of working steel pipe conveying medium technology respectively adopts a welding steel submerged arc spiral seam steel pipe, seamless steel pipe, double-sided.

The 2 insulation layer: use of rigid polyurethane foam.

3: protective shell is made of high density polyethylene or glass steel.

4 leakage alarm line: manufacturing of directly buried heat insulation pipe, in the insulation layer near the pipe, buried with the warning line, once the pipeline leakage alarm line somewhere, by conduction, can be in a dedicated instrumentation alarm and display the location and the degree of leakage Water Leakage big small, to inform the pipe repair personnel quickly processing Water Leakage, guarantee the safe operation of heat supply network.

Three, direct buried insulation pipe performance:

Direct buried insulation pipe has good mechanical performance and heat insulation performance, usually resistant to the high temperature of 120 DEG C through modification or other insulating material resistant to high temperature of 180 DEG C combination, insulation engineering applicable to all kinds of cold, hot water high temperature pipeline.

Four, the advantages of directly buried heat insulation pipe:

1, reduce project cost.

According to estimates by a relevant department, two pipe heating pipe, under normal circumstances can reduce the project cost 25% (made of glass steel as a protective layer) and 10% (using high density polyethylene as a protective layer around).

2 low heat loss, energy saving.

Direct buried insulation pipe of the thermal conductivity coefficient: lambda =0.013 - 0.03kcal/m - H - oC, other than in the past used pipe insulation material is much lower, the insulation effect is increased by 4~9 times. Again the water absorption rate is very low, about 0.2kg/m2. The reason of low water absorption is due to closed cell polyurethane foam rate around 92%. Low thermal conductivity and low water absorption rate, coupled with the thermal insulation layer and the outside good waterproof properties of high density polyethylene or glass steel shell, has changed the traditional trench laying heating pipeline "wear wet jacket" situation, greatly reducing the overall heat loss of heat supply pipeline, network heat loss is 2%, less than 10% of the requirements of international standard.

3, anti-corrosion, insulation performance is good, the service life is long.

Direct buried insulation pipe because of rigid polyurethane foam insulation layer bonded in the steel sheath, cut off the air and water infiltration, can play a good role in anti-corrosion. At the same time, foaming holes it is closed, water absorption is very small. High density polyethylene shell, glass steel shell has good anti-corrosion, insulation and mechanical properties. Therefore, the work pipe sheath hard to erosion of the outside air and water. As long as the internal pipeline water treatment, according to foreign information, directly buried insulating pipe service life can reach more than 50 years, the use of 3~4 times higher than the traditional life and trench laying overhead laying.

4 an area of small, fast construction, is beneficial to environmental protection and reduce the construction people.

Don't need laying large trench buried heating pipe, only the people buried underground heat insulation pipe, thereby greatly reducing the area, reducing the volume of earth excavation about 50% above, to reduce the amount of 90% civil masonry and concrete. At the same time, heat preservation tube processing and on-site trench parallel, simply field joints, can greatly shorten the construction period. Due to the reduction of the brick, cement, sand and gravel, the remnant soil of transportation, thereby reducing the exhaust emission in the process of construction quantity, dust emission, noise emissions, so as to protect the environment.

5, security

At present, in addition to direct buried insulation pipe production outside of China, are equipped with leakage alarm line, once the pipeline leakage alarm line somewhere, by conduction, can show the insulation pipe seepage, leakage and leakage extent accurate position in the special detecting instruments, the pipe section to inform the inspection personnel quickly processing infiltration leakage. To ensure the safe operation of heat supply network. Domestic production of thermal insulation pipe leakage current alarm line end design, need to fill this blank.

Five, direct buried insulation pipe summary:

The total

- Q:Fence material outside the plastic inside is iron or steel this material called

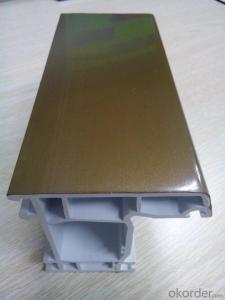

- Generally refers to steel profiles. Plastic profiles are used for the production of doors and windows with PVC profiles, as early as the late 1950s has been in Germany, China began in 1983 from the beginning of the 20th century, the late 90s began universal application. Because simply use PVC profiles processing doors and windows strength is not enough, usually in the cavity to add steel to enhance the stability of doors and windows, so the profile of the steel interior made of plastic doors and windows are often called steel doors and windows. With the extensive use of steel doors and windows, PVC profiles for the production of steel doors and windows are commonly known as steel profiles.

- Q:The state of high-rise residential building doors and windows materials are not allowed to use steel profiles are expressly provided?

- Allows the use of steel profiles. The provisions of the doors and windows with the number of layers does not matter. Now energy-saving requirements, no matter what material, as long as the energy-saving requirements on the line. Aluminum need to use heat type, more expensive, so the use of steel is more common.

- Q:What is the quality of plastic steel profiles in the end?

- The price is relatively high, the quality is also very general above, especially color materials, color one or two years on the fade, and there will be a small part of the broken material problems, the current sell in the southern city a little better. But the supply cycle time is too long, completely delay the duration. And are and business people to communicate, do not see the manufacturers, so afraid to get fake.

- Q:Plastic doors and windows and plastic windows do not like?

- Glass fiber reinforced plastic (FRP) doors and windows 1) abroad to alkali-free glass fiber reinforced, the product surface finish is better, no need to deal with the system can be used directly to the window. Domestic self-developed glass fiber reinforced plastic doors and windows profiles generally with alkali glass fiber reinforced, the surface of the profile after grinding, available electrostatic powder coating, surface coating and other technical processes, access to a variety of colors or texture of the decorative effect. The following are the same as the " 2) Do not use high-alkali glass fiber made of profiles. The following are the same as the " 3) FRP doors and windows profiles have a high longitudinal strength, under normal circumstances, you can not enhance the steel. But the doors and windows size is too large or high wind pressure requirements, should be based on the use of requirements to determine the enhanced approach. The transverse strength of the profile is low. Fiberglass doors and windows frame for the assembly of the turret, the joints need to use sealant seal to prevent leakage of the gap.

- Q:The main features of steel profiles

- In the building construction is mainly used for sliding, sliding doors and windows, fence, pipe and ceiling material applications, through the new process is also widely used in automotive engine protection board, not only light weight, and good toughness, with just fine Nature, and sometimes also known as alloy steel.

- Q:Is not aluminum alloy better than steel?

- Aluminum alloy steel has its own advantages and disadvantages, in general, aluminum alloy is better than steel, high grade. Steel is hard plastic squeeze into the cavity, then will be coupled with the steel lining, which see the strength of the manufacturers of doors and windows, and if the thickness of the steel lining is not enough, a long time will be deformed, but the price is low, because it is plastic So it is not a special heat. Aluminum alloy must be a new type of aluminum, not the kind of the oldest kind of aluminum, the new aluminum cavity and plastic steel is the same, but the material is aluminum, good age, metal is hot fast, but It is also possible to add a kind of insulation material, cold bridge (also called broken bridge), plus this material can solve the problem of insulation, but also can do both positive and negative colors , Aluminum alloy is the high price of the general high-end district are equipped with aluminum alloy.

- Q:What is the steel profile?

- The profile is still visible when the window is still visible

- Q:What is the broken bridge of aluminum? What are the characteristics?

- Broken bridge aluminum bridge is actually aluminum material, but in the middle of the aluminum through the insulation bar, the aluminum cut off the formation of broken bridge, which is characterized by: 1, broken bridge aluminum insulation is good, good air tightness: aluminum-plastic composite profiles in the plastic thermal conductivity is low, good insulation effect, coupled with a good air tightness, in the cold area despite the outdoor minus tens of degrees, Indoor is warm as spring. ?????? 2, broken bridge aluminum sound insulation is good: its structure has been carefully designed, seams tight, using the insulating glass. Test results The sound insulation standard is: 30db, in line with the relevant noise material standards. ?????? 3, broken bridge aluminum is not easy to deformation, impact resistance: the broken aluminum and aluminum plastic composite profile of the outer surface of aluminum alloy material, so it is much stronger than the impact resistance of plastic window profiles, long years of use is not easy to deformation.

- Q:Is the powder produced when the crushed plastic is crushed?

- Plastic crusher Plastic crusher refers to the crushing of various plastic and rubber such as plastic profiles, pipes, rods, silk, film, scrap rubber products. Granules can be directly for extrusion, as the production of raw materials.

- Q:Plastic steel window profile material

- The layman is so to say that there is no grade steel, on a model, the standard requirement is to look at the three sex. ABC blind Mongolia Yeah, you will be the best, the price is not expensive 280 steel is a foreign brand? The highest price in the country, but 170-280. Who's how good you are. Are generally about 170 on the OK.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glass steel pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords