FRP Profile with High Strenth and Light Weight

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

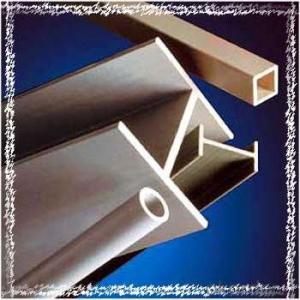

Pultrusion process is a mechanized process for FRP composites involves pulling a collection of fibers in the form of roving mat or fabric through a resin bath and then through a heated die to cure the resin, and then take shapes of profiles. FRP pultruded profiles are more than a kind of structure, which is very designable. Changing the choice of the materials and designs of the lamination process can make special properties for it. It can be widely use in railing, bracket of water circulation tower, sport equipment, tool handle, bracket of tent and others loading structure components

Product Performance:

• Corrosion resistant and anti-ageing

• Water-proof, fire retardant, Heat Resistance

• Light weight, high strength and impact strength

• Non-magnetism and non-conductive

PROFILE TYPE

By changing different shapes of the mould (die), this production line can produce different profiles or rods. The following list is some products photos for reference.

No. | Item | No. | Item |

1 | Rectangular tube | 9 | Cable tray |

2 | Square tube | 10 | Handrail |

3 | Round tube | 11 | Profile for door & window |

4 | Channel | 12 | Guardrail |

5 | I-beam | 13 | End fitting of Radome |

6 | Angel | 14 | Shaft of the umbrella& tent |

7 | Epoxy rod | 15 | Profile for bridge |

8 | Platform and ladder | 16 | Ladder |

Application

The FRP channel products can resist corrosion from various gas or liquid such as acid,alkali,organic solvent and compound.

They can be used as ladder material,and used in the electricity industries.

FAQ:

1.Who will pay for the express cost ?

A: We can support you free samples ,but express cost will be paid by you .

2.How long is the delivery time?

A:within 10-15 days after receiving deposit.

- Q:What is the best thing to add in fiberglass, talcum powder or glass powder or something else, thank you

- Glass fiber is made from glass as a raw material and rolled in a high temperature melting state. Its diameter is generally 0.5-30 microns, and the surface is treated by coupling agent, which improves the adhesive force with resin. It is reinforced material in glass fiber reinforced plastics and mainly provides strength.

- Q:poly fil fiber is 100% polyester and I need to know if its recyclable for a physics project

- Polyester is a man made product - only natural stuff like paper and wood and cloth made from plant fiber would be recyclable.

- Q:I GOT A STAIN ON MY BRAND NEW DRESSNO CLUE HOW I DON‘T HAVE TIME TO WASH IT ANYONE KNOW HOW TO GET IT OUT WITH OUT LEAVING A WATER STAIN?? NOT SURE WHAT IT ISMAY BE GREASE

- No. Wear something else

- Q:What is the synthesis of Polyester?

- Polyester is a category of polymers which contain the ester functional group in their main chain. Although there are many polyesters, the term polyester as a specific material most commonly refers to polyethylene terephthalate (PET). Polyesters include naturally-occurring chemicals, such as in the cutin of plant cuticles, as well as synthetics through step-growth polymerization such as polycarbonate and polybutyrate. Natural polyesters and a few synthetic ones are biodegradable, but most synthetic polyesters are not. Depending on the chemical structure polyester can be a thermoplastic or thermoset, however the most common polyesters are thermoplastics.[1] Woven polyester fabrics are used in apparel and home furnishings such as bed sheets, beds, table sheets, curtains and draperies. Similarly, industrial polyesters are used in tyre reinforcements, ropes, fabrics for conveyor belts, safety belts, coated fabrics and plastic reinforcements with high energy absorption. Polyester fibers are also used to stuff pillows, comforters and cushion padding. Liquid crystalline polyesters are among the first industrially-used liquid crystalline polymers. They are used for their mechanical properties and heat-resistance. These traits are also important in their application as an abradable seal in jet engines. Polyesters are widely used as a finish on high-quality wood products such as guitars, pianos and vehicle / yacht interiors. Burns Guitars, Rolls Royce and Sunseeker are a few companies that use polyesters to finish their products. Thixotropic properties of spray-applicable polyesters make them ideal for use on open-grain timbers, as they can quickly fill wood grain, with a high-build film thickness per coat. Cured polyesters can be sanded and polished to a high-gloss, durable finish

- Q:So I have a pet chinchilla named Sophie and I recently got a hay holder. I don‘t really need it but I thought of a cute idea to turn it into a tent with a soft thing. The thing is so many things are toxic to chinchillas so I don‘t know what to use. Would any of these be good?1. toilet paper2. small blanket3. small wash cloth4. paper5. small part of 100% polyester pajama pantIf you know something else that is soft that will be nontoxic for chinchillas please tell me!Feel free to share tips with me (:

- Any type of polyester is fine

- Q:for my student council we want to have a dance and i thought of a 80‘s themed but i just did not know how to decorate. Any ideas will help. Also what are some good 80‘s cloths for guys. Also some good 80‘s songs would help too

- GUYS: 1 word, POLYESTER if the dance is formal. Rent 16 Candels and take notes. Decor would have been lime colors blue types- work oranges into the mix. Take notes: WHAM. see the colors? the style? Someone in charge must wear a RELAX tee to let everyone know who the boss is. GIRLS: A long sweatshirt w/ leg warmers, topped at the toes w/ a high heeled shoe. Hair is to be sprayed BIG! The bigger the hair, the more 80's you will be. If someone could get a Flock of seagull hair do going that would be sweet. You-Tube a video Valley Girl take notes. That was so big. I hope you have a totally awsome par-tay!

- Q:i‘m doing an artpiece in the style of sigmar polke. I read that he uses a lot of cloth and paints on top of it with things but what kinds of materials did he use to paint? acrylic? spray paint? ink? and what kind of fabric is best to paint on so that the color stays on? cotton, polyester, synthetic fiber, etc?

- If you use acrylic paints, you really don't have to worry what type of fabric you use. Acrylic covers everything! If you have your choice though, choose cotton fabrics. It will soak up the paint without hesitation. Good luck! And show your final project on ETSYLove to see them. Goodluck!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Profile with High Strenth and Light Weight

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords