Frequency Inverter Single-phase 220V class 0.75KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

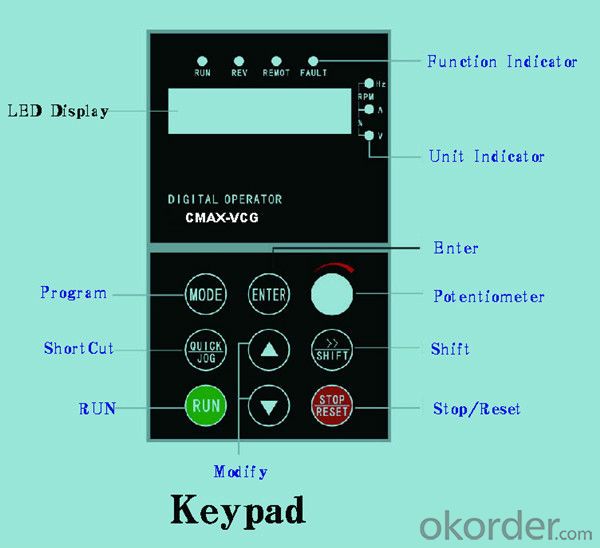

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q:It was when processing a workpiece, processing spindle stops suddenly (other are normal) a check is, I jump out of the inverter, I can click on a processing, and then processing not long after they happen, (do not open the machine spindle machining will also be the case)

- Suggest you in the inverter power installed a frequency converter input filter, try it, feel a bit like electromagnetic interference caused by frequency converter mistakenly stop ah.

- Q:How do you set the frequency with panels?. What are the specific steps?

- Concrete steps are:1, the parameter 700 is the starting signal, the 1 is the panel button starting, and the 2 is the external signal starting;2, the parameter 1000 is the frequency setting value, and the 1 is the panel lifting mark key to change the frequency, and 2 is the external analog signal change.3, the starting signal is set automatically, then the parameter 1000 is 1, the panel is set frequency, and the parameter 1031 is set to 1 so that the frequency value after the change is saved automatically.

- Q:PT100 temperature patrol instrument, when the converter is not open, the measurement is normal. Once opened, it shows completely disorder, and sometimes there are puzzling characters. How can I solve this problem? Please enlighten master!

- In your description of the problem, the patrol instrument shows that there has been a disturbance, then it shows that the patrol meter itself has been greatly disturbed and the work is out of order! If you can't add these two options, you can only change the test scenario.

- Q:What is frequency conversion? What is the function of frequency converter?

- Power factor compensation, energy savingThe reactive power will not only increase the heating power loss and equipment, more important is to reduce the power factor of the power grid leads to the decrease of active power, reactive power consumption in a large number of lines, low efficiency, serious waste of equipment, the use of frequency control devices, the inverter internal filter capacitor, thereby reducing the reactive power loss, increase active power grid.

- Q:I would like to ask vector control of the frequency converter, how the motor does not turn. What parameters are set up

- Because the dynamic mathematical model of induction motor is a high order, nonlinear and strong coupling multivariable system. In the 70s of last century, SIEMENS Engineer F.Blaschke first proposed asynchronous motor vector control theory to solve the AC motor torque control problem. The basic principle of vector control is achieved through the measurement and control of induction motor stator current vector, according to the principle of field orientation respectively, excitation current and torque current of induction motor control, so as to achieve the purpose of controlling the torque of asynchronous motor. In particular the stator current vector is decomposed into a component of current magnetic field (excitation current) and the torque producing current component (torque) to control respectively, and at the same time to control the amplitude and phase of the two components, namely the control of stator current vector, so that this control method is called vector control mode. In brief, the vector control is to decouple the magnetic flux and the torque, which is beneficial to design the regulator of both of them, so as to realize the high speed control of the AC motor. There are vector control methods based on slip frequency control, speed sensorless vector control method and vector control method with speed sensor. Thus, a three-phase induction motor can be equivalent to a DC motor to control, so as to obtain the same static and dynamic performance as the DC speed regulating system. Vector control algorithm has been widely used in Siemens, AB, GE, Fuji and other international large company frequency converter.

- Q:Schneider 303 4KW frequency converter F 013 trouble shooting method

- You see when the alarm is started, or stable operation alarm amount, different times, different analysis

- Q:What are the parameters of the frequency converter? Thank you

- Also called torque compensation, in order to compensate for the motor stator winding resistance caused by low-speed torque reduction, and the low frequency range f/V increased method. When the utility model is set as an automatic, the voltage in the acceleration can be automatically raised to compensate the starting torque, and the motor can be accelerated smoothly. If manual compensation is adopted, according to the load characteristics, especially the starting characteristics of the load, the better curve can be selected through the test. For variable torque load, such as improper selection, the output voltage is too high at low speed, while the phenomenon of waste of electricity, and even the emergence of motor load with a large current, while the speed does not go.

- Q:If you don't plug in the PG card, do you use PLC's PID control?Plug in the PG card and the PLC PID control, which is reliable and precise?

- There are several kinds of closed loop, speed closed loop, temperature / pressure / flow closed loop.Since you're talking about PG cards, then obviously you have to control speed.Generally speaking, the control precision is related to the hardware, and the PLC can also output pulses.If you are small system, simple control, it is recommended that you use PG card + encoder to save the cost, you can inverter internal PID, and control accuracy is also ok.My feeling, as if the speed control precision is high, is PG card.

- Q:Application of ABB frequency converter

- When the motor is powered by an industrial frequency power supply, the current increases when the voltage drops; for the inverter, if the voltage drops when the frequency drops, then does the current increase?When the frequency drops (low speed), if the output is the same power, the current increases, but the current remains almost constant under a certain torque.

- Q:The difference between soft starter and converter

- The soft starter is during the start-up of the equipment to take blood pressure or other ways to reduce the starting current of the inverter machine, the device is in operation according to the equipment load by changing the size of the power frequency and regulating equipment output.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Frequency Inverter Single-phase 220V class 0.75KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords