Frame-Connected Scaffolding for Civil Construction and Industrial

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

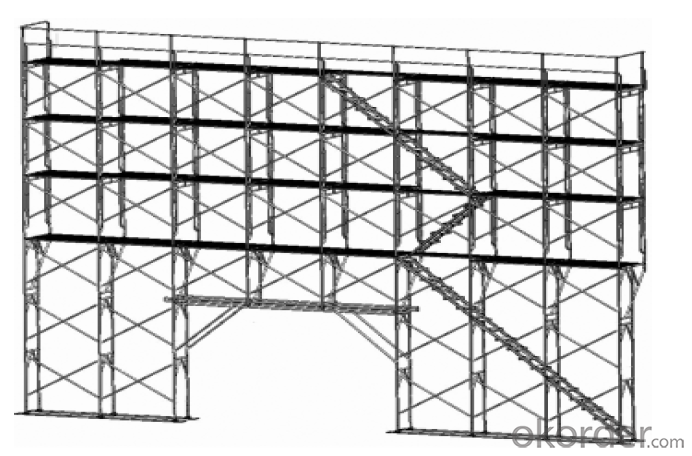

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Frame-Connected Scaffolding Images

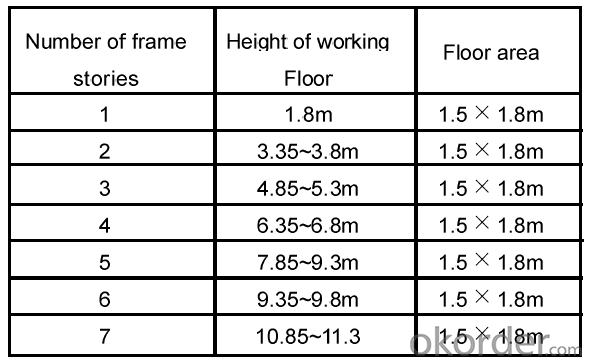

4. Frame-Connected Scaffolding Specification

.Maximum breaking load: 22.2t

.Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:I want to do something like this for an engagement ring…

- I got the nice diamond solitare to go with it. Came out perfect. Lots of jewlers make wraps of all kinds. I would check out alot of places before making a desision.

- Q:Can steel tube couplers be used in scaffolding projects that require access through walls or openings?

- Yes, steel tube couplers can be used in scaffolding projects that require access through walls or openings. These couplers allow for secure and sturdy connections between steel tubes, allowing scaffolding to be easily maneuvered and adjusted to fit through narrow spaces or openings in walls. They provide a reliable solution for scaffolding projects that require access through walls or openings.

- Q:While standing on a long board resting on a scaffold, a 60 kg painter paints the side of a house. If the mass of the board is 13 kg, how close to the end can the painter stand without tipping the board over?

- It very much depends on how and where (at which points along its length) the board is supported by the scaffold.

- Q:Can steel tube couplers be used in scaffolding applications with curved or irregular shapes?

- Yes, steel tube couplers can be used in scaffolding applications with curved or irregular shapes. They are versatile and can be adjusted to fit various angles and shapes, providing stability and strength to the scaffolding structure.

- Q:Can steel tube couplers be used for both indoor and outdoor scaffolding?

- Yes, steel tube couplers can be used for both indoor and outdoor scaffolding. Steel is a durable and weather-resistant material, making it suitable for various environments.

- Q:Are steel tube couplers suitable for supporting platforms or decking on scaffolding?

- Steel tube couplers are a great option for supporting platforms or decking on scaffolding. Designed to securely connect steel tubes, they offer a strong and reliable connection. These couplers are frequently used in scaffolding systems to create a stable platform for workers to reach higher areas. Not only are they durable and capable of handling heavy loads, but they are also easy to install and can be adjusted to different angles and positions. This flexibility allows for various scaffolding designs. In summary, steel tube couplers are a reliable and efficient choice for supporting platforms or decking on scaffolding.

- Q:What is the average lifespan of a steel tube coupler?

- The average lifespan of a steel tube coupler can vary depending on several factors such as the quality of the coupler, its usage conditions, and maintenance practices. However, in general, a well-maintained steel tube coupler can have a lifespan of around 20 to 30 years. Regular inspections and proper maintenance can help extend the lifespan of a steel tube coupler. This includes checking for signs of wear or damage, ensuring proper lubrication, and addressing any issues promptly. Additionally, using the coupler within its recommended load and stress limits can also contribute to its longevity. It's important to note that the lifespan of a steel tube coupler can be affected by various external factors such as exposure to harsh weather conditions, excessive vibrations, or corrosive environments. Therefore, it is crucial to consider these factors and implement appropriate preventive measures to ensure the longevity and safety of the coupler. Ultimately, the lifespan of a steel tube coupler can vary, and it is recommended to consult with manufacturers or industry experts for more precise estimations based on specific usage conditions and maintenance practices.

- Q:What are the common failure modes of steel tube couplers in scaffolding?

- Several factors can be attributed to the common failure modes of steel tube couplers in scaffolding. One of these modes is overloading, which occurs when the weight or load applied to the scaffolding surpasses the coupler's maximum load capacity. As a result, the coupler can deform, crack, or even break, leading to a catastrophic failure of the entire scaffolding structure. Improper installation or assembly of the couplers is another failure mode to consider. If the couplers are not properly tightened or aligned, they can become loose or detached, posing a significant safety risk. This improper installation can also create gaps or misalignment between the tubes, compromising the overall strength and stability of the scaffold. The corrosion of steel tube couplers is yet another failure mode to be aware of. Over time, exposure to moisture, chemicals, or other corrosive agents can cause the couplers to rust or corrode. This weakens the structural integrity of the couplers, making them prone to failure under load. Fatigue failure is also common in steel tube couplers. The repeated application of loads, such as during the construction or dismantling of the scaffold, can lead to the development of cracks or fractures in the couplers over time. These cracks can propagate and eventually result in a complete failure of the coupler. Finally, poor quality or substandard manufacturing can contribute to failure modes in steel tube couplers. If the couplers do not meet industry standards or are made from low-quality materials, they may lack the necessary strength and durability, making failure more likely. To prevent these failure modes, it is crucial to ensure that the scaffolding design is appropriate for the intended load and usage. Regular inspections and maintenance should be carried out to identify any signs of wear, corrosion, or damage to the couplers. Proper training and education of personnel involved in the assembly and disassembly of scaffolding are also essential to ensure correct installation and alignment of the couplers. Using high-quality and corrosion-resistant couplers, as well as following manufacturer guidelines and industry best practices, can also help prevent the common failure modes of steel tube couplers in scaffolding.

- Q:Can steel tube couplers be used in scaffolding projects with specific weight-bearing requirements?

- Indeed, steel tube couplers possess the capability to be implemented in scaffolding ventures that entail precise weight-bearing prerequisites. These couplers have been ingeniously designed to facilitate the connection of two steel tubes, thereby crafting a robust and steadfast linkage. It is imperative to note that these couplers are meticulously manufactured in accordance with industry standards, and thorough testing is conducted to ascertain their aptitude for bearing substantial loads. When one is confronted with the task of selecting steel tube couplers for a scaffolding endeavor that necessitates specific weight-bearing capabilities, it is of paramount importance to deliberate upon the load capacity of said couplers. Different categories of couplers may exhibit disparate load capacities, rendering it indispensable to choose an appropriate coupler contingent upon the projected weight that the scaffolding is expected to support. Moreover, adhering to the manufacturer's guidelines and recommendations concerning the utilization of steel tube couplers in scaffolding projects is essential. This encompasses the meticulous application of installation techniques, ensuring that the couplers are properly fastened and securely tightened to the steel tubes. Furthermore, it is imperative to conduct regular inspections and maintenance of the entire scaffolding system to guarantee the continued safety and ability of the steel tube couplers and the structure as a whole to meet the weight-bearing prerequisites. In summation, steel tube couplers possess the potential to be employed in scaffolding projects with specific weight-bearing requirements. Nonetheless, it is crucial to meticulously select the appropriate coupler based on its load capacity and abide by the manufacturer's guidelines for installation and maintenance to safeguard the well-being and structural integrity of the scaffolding.

- Q:Building construction bowl button steel pipe scaffolding and fastener scaffolding which cost high

- Polystyrene foam board is the cheapest, extruded board is good but expensive

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Frame-Connected Scaffolding for Civil Construction and Industrial

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products