Cost Effective Slab Formwork System with Quick - Striking Head Jack

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

1.Concrete slab formwork

2.Cost effective

Cost Effective Slab Formwork System with Quick - Striking Head JackDescription:

Brief introduction

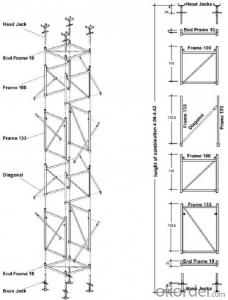

Alu-slab system is widely used for pouring slab concrete, especially for the building which has higher story height that only using props can’t meet requirements. The system guarantees quick assembly, simple structure and easily operation, with more important, it can achieve early & quick removing for parts materials; it is good choice for slab construction if you want to do cost effective construction.

Competitive advantage

① Cost effective

EA-REMO system has an important member which is called “quick-striking head jack”, with which will achieve quick & early removing for parts formwork system, it is fast to remove and turnover, so EA-REMO system guarantees cost effective construction.

②Flexible application

Unlike table formwork, EA-REMO system is composed of scattered element, so comparatively speaking, it will be easily to adapt to different building structures. No matter what shape your structure is, rectangular, circular, cambered, even irregular shape, it will always do a good work.

③Simple structure, easy operation.

The formwork is composed of plywood, main beam, secondary beam, connectors and cup-lock scaffolding support system. It’s easy to assemble for labors with simple structure. Special skill train is no needed.

④Height of scaffolding is adjustable

Table formwork is supported with adjustable scaffoldings; the scaffoldings can be pivoted in two directions for meeting the demand of different height with adjustable head jack and adjustable foot jack.

Applications

- Q:What are the advantages of a new self-locking construction fastener?

- Try to wrap the water tank with a heat shield. In the inside you can first use wood to customize a box. And then use the insulation film wrapped from the outside, but the insulation film needs to choose a good material there is a way is now a new type of environmentally friendly and efficient insulation materials - vacuum insulation board with a vacuum insulation board Insulation effect, not only in the summer can greatly reduce the indoor temperature, so you have a cool energy-saving summer, and can play an effective winter insulation effect. Can be described as Dongnuanxialiang high quality green building materials. And its price is quite favorable

- Q:What are the common reasons for failure or malfunction of steel tube couplers?

- There are several common reasons for failure or malfunction of steel tube couplers. One of the primary reasons is improper installation. If the coupler is not properly aligned and tightened, it can lead to misalignment or slippage, causing the joint to fail. It is crucial to follow the manufacturer's guidelines and use the correct tools to ensure a secure and tight connection. Another common reason is corrosion. Steel tube couplers are often exposed to various environmental conditions, such as moisture, chemicals, or extreme temperatures, which can lead to corrosion. Over time, this corrosion can weaken the coupler and compromise its structural integrity, eventually resulting in failure. Inadequate maintenance or neglect can also contribute to the failure of steel tube couplers. Regular inspections, cleaning, and lubrication are necessary to prevent the accumulation of dirt, debris, or rust that can hinder the proper functioning of the coupler. Failure to maintain the couplers can accelerate their deterioration and increase the risk of malfunction. Furthermore, exceeding the load capacity is a significant cause of failure. If the coupler is subjected to excessive loads or stresses beyond its design specifications, it can result in deformation, cracking, or even complete failure of the joint. It is crucial to ensure that the coupler is used within its recommended load limits to prevent any potential failures. Lastly, poor quality materials or manufacturing defects can also contribute to the failure or malfunction of steel tube couplers. In some cases, the couplers may have weak spots, inconsistencies, or defects that compromise their strength and durability. It is essential to source couplers from reputable manufacturers and suppliers to minimize the risk of receiving faulty products. In conclusion, the common reasons for failure or malfunction of steel tube couplers include improper installation, corrosion, inadequate maintenance, exceeding load capacity, and poor quality materials or manufacturing defects. By addressing and preventing these issues, the reliability and performance of steel tube couplers can be significantly improved.

- Q:In the hands of a few projects, to use steel pipe, fasteners, scaffolding, location in Luotian, open the first project is twenty thousand square, high eight, duration of eight Months, there are other projects to several thousand tons. I think this is a chance. what should I do? Thank you. More

- Need, the fire limit is half an hour, need to apply fire retardant coating.

- Q:Can steel tube couplers be used in scaffolding projects involving complex or intricate geometries?

- Yes, steel tube couplers can be used in scaffolding projects involving complex or intricate geometries. These couplers are versatile and can be adjusted to fit various angles and shapes, allowing for the construction of scaffolding structures in intricate or irregular geometries.

- Q:Can steel tube couplers be used for scaffolding structures that need to support cantilevered platforms?

- Yes, steel tube couplers can be used for scaffolding structures that need to support cantilevered platforms. Steel tube couplers are commonly used in scaffolding systems to connect and secure the tubes together, creating a stable and sturdy structure. Cantilevered platforms are supported by extending the scaffold tubes beyond the main structure, and steel tube couplers can be used to connect these extended tubes securely. However, it is important to ensure that the scaffolding is designed and assembled by professionals following safety guidelines and regulations to ensure the stability and safety of the structure.

- Q:What safety measures should be taken when working with steel tube couplers in scaffolding?

- When working with steel tube couplers in scaffolding, several safety measures should be taken to ensure safe operations. Firstly, it is crucial to inspect the couplers for any damages or defects before use. This includes checking for cracks, deformities, or signs of wear that could compromise their strength and stability. Additionally, proper training should be provided to all workers involved in using steel tube couplers. They should be educated on the correct techniques for assembling and dismantling scaffolding, as well as the weight limits and load capacities of the couplers. This will help prevent overloading and potential collapses. Furthermore, it is essential to secure the couplers tightly to the tubes to prevent any dislodging or movement during use. This can be done by ensuring that all bolts and nuts are properly tightened and regularly checked for any loosening. Lastly, regular inspections and maintenance of the couplers and scaffolding system should be conducted to identify any issues promptly. Any faulty or damaged couplers should be replaced immediately to prevent accidents or structural failures. By following these safety measures, the risks associated with working with steel tube couplers in scaffolding can be minimized, ensuring a safer working environment for all.

- Q:Are there any specific safety guidelines for using steel tube couplers in scaffolding?

- Yes, there are specific safety guidelines for using steel tube couplers in scaffolding. Firstly, it is important to ensure that the couplers used are of high quality and meet the required standards. They should be properly manufactured and fit for purpose. It is recommended to use couplers that have been tested and approved by relevant authorities or organizations. Secondly, it is crucial to inspect the couplers before use. This includes checking for any signs of damage, wear, or corrosion. If any defects are found, the couplers should be replaced immediately. Additionally, it is essential to properly secure the couplers to the scaffold tubes. This can be done by fully tightening the bolts or clamps as per the manufacturer's instructions. Loose or improperly secured couplers can result in instability and pose a safety risk. Furthermore, when erecting scaffolding with steel tube couplers, it is important to follow the manufacturer's guidelines and industry best practices. This includes ensuring that the scaffold is properly braced, level, and plumb, and that the correct number and type of couplers are used to provide adequate support and stability. Regular inspections and maintenance of the couplers and scaffolding are also necessary to ensure ongoing safety. This includes checking for any signs of damage, wear, or movement, and addressing any issues promptly. In summary, specific safety guidelines for using steel tube couplers in scaffolding include using high-quality couplers, inspecting them before use, properly securing them to scaffold tubes, following manufacturer's guidelines, conducting regular inspections and maintenance, and adhering to industry best practices. By following these guidelines, the risk of accidents or failures can be minimized, ensuring a safe working environment for those using the scaffolding.

- Q:What are the common warranty terms for steel tube couplers in scaffolding?

- The common warranty terms for steel tube couplers in scaffolding typically include a warranty period of one year from the date of purchase. During this period, the couplers are warranted to be free from defects in material and workmanship. However, the warranty does not cover damage caused by misuse, improper installation, or normal wear and tear. It is important to read and understand the specific warranty terms provided by the manufacturer or supplier of the steel tube couplers.

- Q:Can steel tube couplers be used in scaffolding projects with limited access?

- Yes, steel tube couplers can be used in scaffolding projects with limited access. Steel tube couplers are versatile and can be easily used in confined spaces where traditional scaffolding may not be feasible. They provide a secure connection between tubes, allowing for the construction of scaffolding in tight or hard-to-reach areas.

- Q:Can steel tube couplers be used for suspended scaffolding systems?

- Indeed, suspended scaffolding systems can make use of steel tube couplers. These couplers, which are frequently employed in the construction field, effectively join and fasten steel tubes, resulting in a sturdy and dependable structure. When it comes to suspended scaffolding systems, steel tube couplers serve to connect the different elements of the system, including the vertical tubes, horizontal tubes, and diagonal bracing, guaranteeing the overall stability and safety of the scaffolding. Specifically engineered to withstand substantial loads and offer a secure attachment, these couplers prove to be highly suitable for deployment in suspended scaffolding systems, where safety is of utmost importance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cost Effective Slab Formwork System with Quick - Striking Head Jack

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords