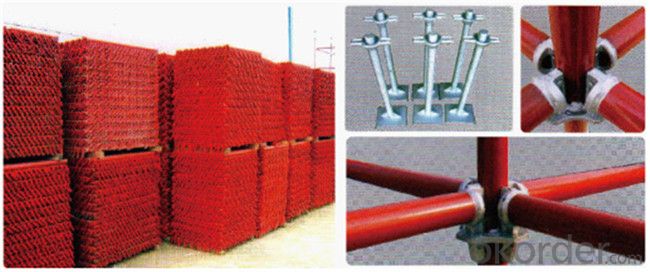

Pulley-clip Scaffolding

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pulley-clip Scaffolding

Features:

①Safe & Stable The pulley-clip scaffold has perfect mechanical properties:The theoretical data of the eccentric distance of the vertical pole joints of pulley-clip scaffold is zero,which improves the axial compressive strength of the vertical poles,plays the mechanical properties of the material and impressive entire stability.Furthermore,the tensile forces and pressures on each joint of the pulley-clip scaffold in operation are in reasonable distribution state,which ensures the pulley-clip scaffold has perfect rigidity and entire stability.

②Efficient & Economic By the statistics,the connecting and dismounting efficiency of pulley-clip scaffold is 6-8 tines higher than coupler scaffold,5-7 times higher than frame scaffold,3-4 times higher than cup-lock scaffolding.The steel tube scaffold does not have any special locking part structurally, which greatly improves the locking reliability..The connecting and dismounting speed is fast with distinct effect in high rise and high altitude operation.Simple process saves construction time and effort,and reduces labor intensity.

③Ultra-low Loss Realize that the steel scaffold does not have moving spare parts strcturally and solve the easy loss,

Easy damage and uneasy transportation problems of the spare parts of the scaffold. The building and dismounting are safer with more distinct role in high-rise and high altitude operations. The lost and stolen rate is below 0.5%.

④Wide Application It adapts to the technical characteristics and economic characteristics of the engineering, can be used independently and solves the problem of joint use with the cup lock scaffold, which provides convenience in technology and economic benefit for the building site which has used cup lock scaffold in large amount to use pulley-clip scaffold.

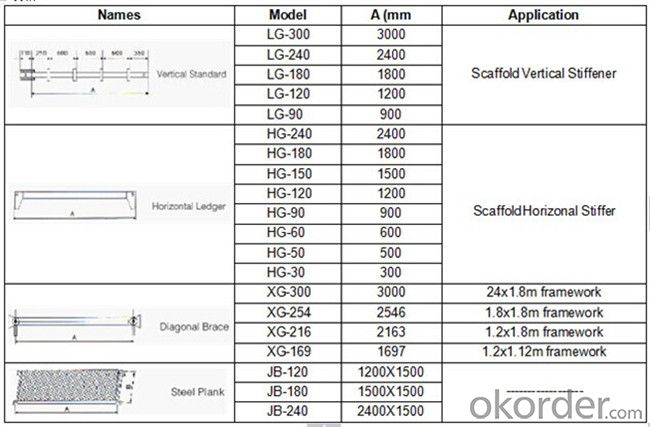

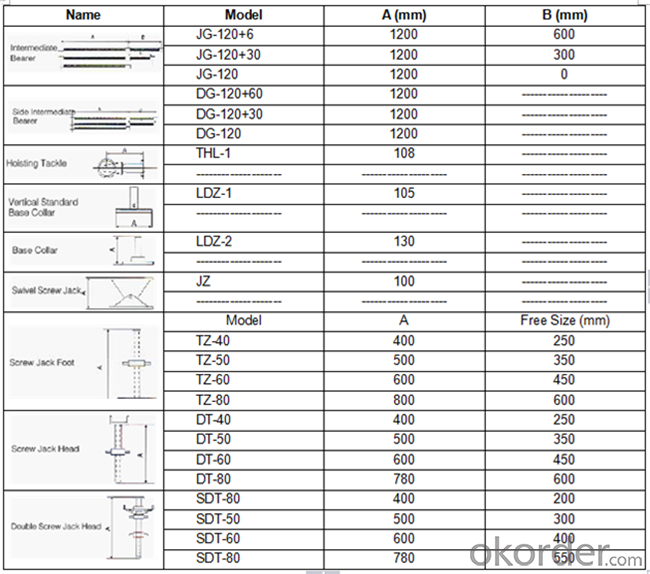

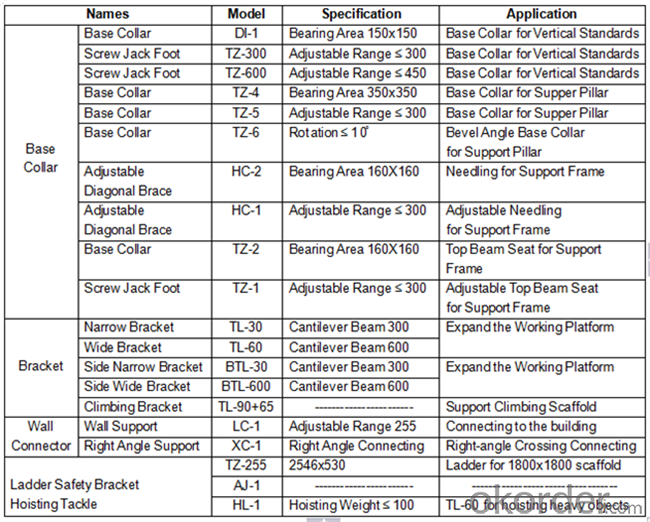

Parameters:

- Q:What is the typical weight limit for steel tube couplers in scaffolding?

- The weight limit for steel tube couplers in scaffolding can vary due to various factors, including the type of coupler, manufacturer's specifications, and intended use. In general, most steel tube couplers used in scaffolding systems can handle loads between 500 and 1000 kilograms (1100 to 2200 pounds) per coupler. To ensure safe and correct usage, it is essential to refer to the manufacturer's documentation or consult a scaffolding engineer to determine the precise weight limit for a specific type of steel tube coupler.

- Q:What are the common materials used to manufacture steel tube couplers for scaffolding?

- Steel tube couplers for scaffolding are typically made from high-quality steel alloys. These alloys are selected for their strength, durability, and ability to withstand heavy loads and harsh environments. Commonly used steel alloys include carbon steel, stainless steel, and alloy steel. Carbon steel is often chosen for its affordability and strength, while stainless steel is preferred for its resistance to corrosion. On the other hand, alloy steel is a combination of different metals that enhances specific properties like strength or heat resistance. The choice of material for manufacturing steel tube couplers may vary based on factors such as the intended application, load-bearing requirements, and environmental conditions. To ensure the safety and reliability of scaffolding structures, it is crucial to utilize high-quality materials.

- Q:i have found a really nice 14 gauge scaffold barbell, would i have to have it done professionally to get it into the holes, or is there someway i can make the holes bigger myself? does this make any sense? i dont think i did. but thanks if you can help me xoxo

- There's no way you could do that piercing yourself and expect it to be lined up correctly. Also, earrings are not appropriate to do body piercings with, and cartilage isn't meant to be stretched. Get pierced by a professional.

- Q:Yes i have one on my top piercing. i went out and boughtzinc tables, peroxide water, vitamin e, asprin which i have to crush a in cup of water and put on my ear..but anyway, the reason why i have one if because my piercer put two rings in, insted of 2 small bars..i cant get my bar until my bump is completely gone, so what im asking is.will it go?can i keep my scaffold/industrial piercing?how long will it take?thanks

- Some places do and some places don't. For one Clairs is only equipt to do first and second holes the FIRST time. anything after that you have to go to places that do more than just ears because it might have to be done with something stronger than a piercing gun. I recommend tattoo shops that have piercers as well. They will be able to do it.

- Q:Are steel tube couplers suitable for temporary or permanent scaffolding installations?

- Yes, steel tube couplers are suitable for both temporary and permanent scaffolding installations. These couplers are designed to securely connect steel tubes, providing a strong and stable scaffolding structure. They are easy to install, adjustable, and can withstand heavy loads, making them ideal for a variety of scaffolding applications, whether temporary or permanent.

- Q:Can steel tube couplers be used for both straight and curved scaffolding designs?

- Yes, steel tube couplers can be used for both straight and curved scaffolding designs.

- Q:What are the common sizes and dimensions of steel tube couplers for scaffolding?

- The most common sizes and dimensions of steel tube couplers for scaffolding are typically 48.3mm (1.9 inches) in diameter and have a standard length of 48.3mm or 48.6mm (1.9 or 1.91 inches).

- Q:How do steel tube couplers contribute to the stability of scaffolding towers?

- Steel tube couplers contribute to the stability of scaffolding towers by securely connecting the steel tubes together, forming a rigid and stable structure. These couplers are designed to provide strong and reliable connections, ensuring that the scaffolding remains stable and safe during construction work.

- Q:How do steel tube couplers prevent slippage or movement of scaffolding tubes?

- Steel tube couplers prevent slippage or movement of scaffolding tubes by providing a secure and reliable connection between the tubes. These couplers are designed to tightly grip the ends of the tubes, ensuring that they remain in place and do not slide or shift during use. The design of steel tube couplers includes internal teeth or gripping mechanisms that engage with the surface of the tubes, creating a strong connection. When the coupler is tightened, these teeth or mechanisms dig into the tube's surface, effectively preventing slippage. Additionally, steel tube couplers are often equipped with bolts or locking mechanisms that further enhance the stability of the connection. These bolts are tightened to create a firm grip and eliminate any potential movement or rotation of the tubes. Furthermore, the material used in steel tube couplers, typically high-quality steel, provides excellent strength and durability. This ensures that the couplers can withstand the weight and forces exerted on the scaffolding, reinforcing their ability to prevent slippage or movement. Overall, steel tube couplers play a crucial role in maintaining the stability and safety of scaffolding structures. Their secure connection prevents any unwanted slippage or movement, allowing workers to perform their tasks with confidence and ensuring the integrity of the scaffolding system.

- Q:What is the typical maintenance routine for steel tube couplers in scaffolding?

- The typical maintenance routine for steel tube couplers in scaffolding involves regular inspections to check for any signs of wear, damage, or corrosion. These inspections should be done before and after each use of the scaffolding system. Additionally, the couplers should be cleaned and lubricated regularly to ensure smooth operation and prevent rust formation. If any issues are detected during the inspections, the couplers should be replaced or repaired immediately to maintain the safety and integrity of the scaffolding structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pulley-clip Scaffolding

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords