Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

1. Features for Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

Size: 20mm-150mm(Dia0.75''-Dia6'')

Hardness: HRC60-HRC65

Low Breakage Rate<0.5%

Impact Toughness>12J/cm2

Endurance Test>10000times

Good Wear Resistant

2. Chemical Composition for Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

Brand | Grade | C | Mn | Si | Cr | S | P |

CMAX-1 | 50Mn | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | 0.25max | 0.035max | 0.035max |

CMAX-2 | 60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | 0.25max | 0.035max | 0.035max |

CMAX-3 | 65Mn | 0.6-0.7 | 0.9-1.2 | 0.17-0.37 | 0.25max | 0.035max | 0.035max |

CMAX-4 | 75MnCr | 0.70-0.85 | 0.7-0.8 | 0.17-0.37 | 0.2-0.7 | 0.03max | 0.03max |

CMAX-5 | Rail IronⅠ | 0.5-0.65 | 0.60-1.0 | 0.15-0.37 | 0.25max | 0.04max | 0.04max |

CMAX-6 | Rail IronⅡ | 0.60-0.8 | 0.90-1.2 | 0.20-0.40 | 0.20-0.8 | 0.07max | 0.03max |

3. Weight and Microstructure for Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

Norminal Diameter | Diametrical Tolerance(mm) | Approx Weight of Single Ball(kg) | Average Number of One MT | Microstructure |

25mm/1'' | +1.5,-0.5 | 0.064 | 15625 | M+B+C (M-Martensite;B-Bainitic;C-Carbide) |

30mm/1.25'' | +1.5,-0.5 | 0.11 | 9090 | |

40mm/1.5'' | +2.0,-1.0 | 0.26 | 3846 | |

50mm/2'' | +2.0,-1.0 | 0.51 | 1961 | |

60mm/2.5'' | +3.0,-2.0 | 0.89 | 1124 | |

70mm/2.75'' | +3.0,-2.0 | 1.4 | 714 | |

80mm/3.25'' | +3.0,-2.0 | 2.1 | 476 | |

90mm/3.5'' | +3.0,-2.0 | 3 | 333 | |

100mm/4'' | +4.0,-3.0 | 4.1 | 244 | |

110mm/4.5'' | +4.0,-3.0 | 5.47 | 283 | |

120mm/4.75 | +4.0,-3.0 | 7.1 | 141 | |

130mm/5'' | +4.0,-3.0 | 9.02 | 111 |

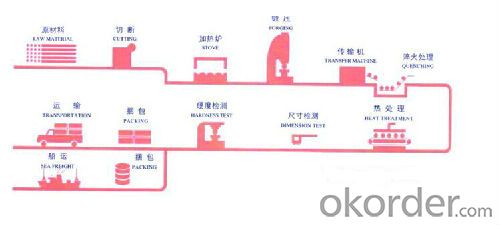

4. Production Process for Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

5. Packing Ways for Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

- Q:It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- 1, qualified enterprises will directly iron ore into molten iron, and then poured into the mold, such a good product performance. I work in the cast iron industry, which I can tell you for sure.2, this, like the Great Wall Motor Company has its own parts production department, as well as the corresponding mold center, so it will be their own casting. If the manufacturer does not have these departments, they can only place orders for others to do.

- Q:What are the casting parts used to test shrinkage holes?

- 3 fluorescent magnetic powder, this method can also be found in part.

- Q:In theory, which is more expensive, forging parts or casting parts?

- It depends on the structure. In theory, the shape of the forging is relatively simple, but the requirement of internal structure is relatively high

- Q:How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- Yantai five God casting is generally 53 yuan /kg, the appearance is quite beautiful

- Q:Domestic large steel castings factory which is better, recommend!

- At least spend money on research and development, then the quality should be all right.

- Q:What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Die die must charge, wood cheap, expensive aluminum mold

- Q:What is the reason for 304 stainless steel precision casting parts to be changed?

- 304 stainless steel is easier to change than ordinary steel. Because the 304 heat conductivity is lower than that of the low doped steel, the temperature is even more uneven, and 20% of the non ferrous elements also make the distribution of internal and external elements more uneven, hard and soft inside. Each of these two produces greater internal stresses, resulting in a variant.

- Q:The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q:Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- The tolerance of a specific size can be obtained from the tolerance grade and nominal size of the casting.

- Q:What are the casting parts tested?

- The surface brightness, appearance, size, chemical composition, weight, material, surface defects, internal defects, seals need to be checked, leakage, etc.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords