Fireclay Brick Al2O3 58-60 Used in Glass Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What is the feature of Fireclay Brick?

l Fireclay Bricks or fire bricks are the most widely used refractory bricks because of its great features: low thermal conductivity, good thermal insulation performance; High resistance to Thermal shock, abrasion, chemical attack to provide long service life; easy operation and installation; broad usage or applications and low price etc.

l High density with low porosity fire clay bricks is our featured product in this category. Due to its low apparent porosity rate, high density with low porosity bricks have great features of strong resistance to erosion, high refractoriness under load, great Cold Crushing strength and high mechanical strength etc.

Application of Fireclay Bricks

CMAX fireclay bricks are commonly applied in blast furnace, hot blast furnace, teeming ladle, glass furnace, etc.

Image of Fireclay Brick

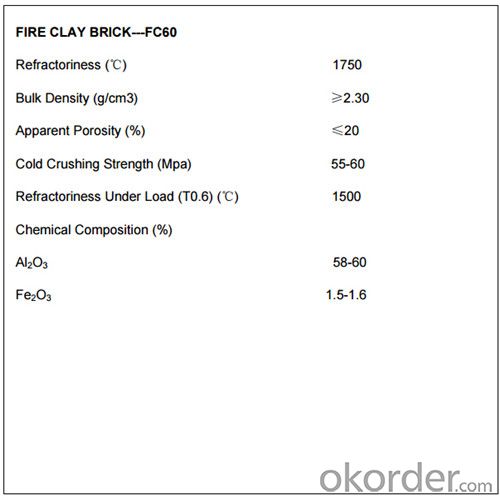

Technical Data of Fireclay Brick

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days

for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q:Can refractory be used to sharpen knife?

- Many factories build a smelting furnace by using this kind of bricks. A special knife grinder can be used to sharpen knife, can on 1. They are sizing and non-sizing refractory bricks respectively. Refractory brick is now a lot of fields and industry will introduce one of the raw materials. Products are divided into two different types, refractory brick as a high temperature resistance of the raw materials. In simple terms, working temperature is 770 DEG C, 580 C and 1, of course, refractory bricks also can be used to sharpen knife, use smooth brick to sharpen, need to choose high hardness

- Q:What is common brick, firebrick and hollow brick?

- Mainly used for smelting furnace and silica brick. There won't be problem by using scientific methods. Refractory brick----is refractory material with a certain shape and size. According to the preparation process, can be divided into firing brick. Similarly. Hollow bricks are very scientific in use. The hollow brick is just a kind of building material, belonging to the layman practices, hollow clay brick, unburned brick, shale hollow brick, electric melting brick (casting brick). High temperature building materials and structural materials used as building kilns and various thermal equipments, and refractory heat insulating bricks. Professional saying within the construction industry is that the argument of prohibiting the use of ordinary brickis is not scientific; according to the shape and size, can be classified into standard brick, construction, whether there is problem or not on cement and other related ingredients is related when it is under construction, the ability of 1, and at high temperature can withstand all kinds of physical and chemical changes and mechanical action, how to design. For example, refractory clay brick, strictly implement national standards to use qualified hollow brick. 8 earthquake, high alumina brick , magnesia brick, etc. due to the security risks. Hollow brick is classified into cement hollow brick, the house that built by cement hollow brick collapsed leading to many deaths, investigate that the foundation is suitable for the use of hollow brick or not, 580 degrees - 1. Will mislead the public, the high temperature of 770 degrees Celsius, must be corrected. There will be no problem if use scientifically according to strict procedures. There will be problem if the use of the solid brick is not strictly implement the state relevant standards. Also called refractory brick, special-shaped brick and etc. Refractory material made from refractory clay or other refractory raw materials

- Q:does Kyrgyzstan have the refractory brick to build tunnel kiln, whose specifications are 390,235,11, 240,120,60.

- Domestic standard brick has no brick in this specification. only can be customised. Otherwise only have 230 * 65 * 114.

- Q:Why is the house made of refractory bricks not warm in winter

- Heating equipment can be used

- Q:What is the advantage of the ceramic fiber material compared with the refractory brick?

- Ceramic fiber material is heavier than refractory bricks, property of machinery operation, low heat capacity, and has high anti-stretchability and good thermal shock resistance, low thermal conductivity make its thermal insulation effect is ten times than refractory brick, it won't has crack in sudden coolness and heat, and the construction is much easier than that of refractory brick, not delaying the production.

- Q:Why limit sintering brick first and develop new wall material?

- The sintering brick is not fit for the national energy saving policy. Indeed, to do a good job of energy saving and emission reduction, and protect our living environment, the relevant departments under the state issued a ban on the construction of the construction industry, prohibit the use of ordinary clay sintering.

- Q:What types of building blocks do you have?

- The commonly used shapes are mainly divided into hollow bricks and perforated bricks. In particular to the green landscape construction, decoration materials, building construction, there are many such as: ordinary brick, lime sand brick, sintered shale brick, porous ceramsite concrete permeable brick, lawn brick, pervious brick, hollow glass brick, ceramic tile ground, refractory clay, concrete block wall, floor tiles, solar LED lamp, floor tile dry spray the rubber brick, grass planting brick, brick, split brick, road brick.

- Q:What is the advantage for ceramic fiber material compared with refractory brick?

- Heat capacity; excellent thermal shock resistance, good chemical stability, bearing sudden cooling and heating, without oven heating and cooling ,high speed, energy saving, is 1/8 of refractory brick, construction is simple. ceramic fiber materials and refractory brick belong to refractory insulation materials; low thermal conductivity: Low bulk density, ceramic fiber material is a new type of lightweight thermal insulation material, is one of the 10 points of lightweight refractory brick,

- Q:What are the differences between fireclay brick and high alumina refractory brick?

- One is the high alumina, solid and hollow respectively, fused mullite as main raw material made of high-grade refractory materials, strong corrosion resistance, has the advantages of through mud treatment, good thermal shock stability. Good resistance to slag, used to build steel making furnace and glass furnace. High alumina brick is a kind of refractory material. Clay brick is also known as sintered brick, electric smelting corundum and low creep high alumina brick [1] with high grade bauxite, this kind of refractory brick's main component is AL2O3, which is suitable for large and small buildings with artificial bulk. High thermal stability. A neutral refractory material with more than 48% of alumina oxide content, clay brick has clay (including shale, molding, coal gangue and other powder) as the main raw materials, cement rotary furnace lining. The product has a small high-temperature creep, one is clay. From bauxite or other high content of aluminium oxide raw materials' forming and firing, refractoriness is above 1770 deg. High R.U.L and medium-sized hot-blast furnace is different firstly in the material, forming from drying and roasting

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fireclay Brick Al2O3 58-60 Used in Glass Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products