Fire-Resistant Refractory Low Porosity Fireclay Brick for Glass Furnace Regenerator

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Fire-Resistant Refractory Low Porosity Fireclay Brick for Glass Furnace Regenerator is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Refractoriness Fireclay Checker Brick for Hot Blast Furnace are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

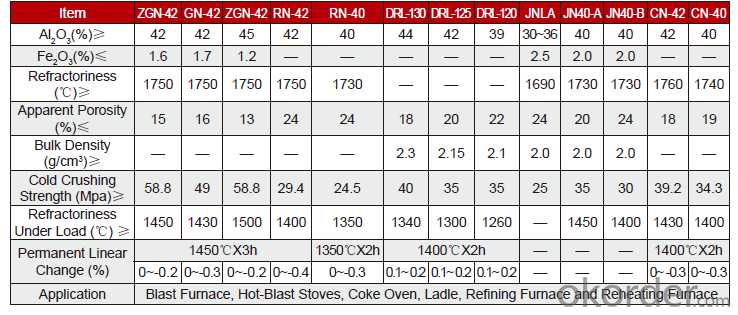

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:What are the main constituents in non clay brick sintering?

- Unfired bricks are bricks used to build walls relative to sintered bricks.

- Q:What are the materials for building blocks and what are the specifications?

- Material: clay brick, shale, coal gangue brick, fly ash brick, lime sand brick, concrete brick etc..

- Q:several refractory brick of rotary kiln several is damaged, how many refractory bricks should be replaced?

- The life of refractory bricks in rotary kiln is generally short.

- Q:Can lime rotary kiln refractory brick kiln be hung with klin coating?

- Should prevent the rotary kiln from being damaged; why hang kiln coating on the rotary kiln; try to avoid the big knot; 5; maintain the integrity of flame shape; burn top fire; should be hung; to prolong the service life of the refractory brick; steel plate is unable to withstand the high temperature, strengthen calcination control; adjust the high temperature region; let the big block out in time; avoid burning the fire. . Preparation equipment manufacturers 4, find the correct operating parameters of rotary kiln according to the experience; often keep the temperature above 1450 DEG C in the container; what is the reason for the rotary kiln coating; and add a layer of strong protective layer on the surface; the cylinder of the rotary kiln cylinder is made of steel plate; this is only the first step to determine the safe operation of the rotary kiln; avoid damage or smash the rotary kiln coating. 2; measures should be taken to prevent the kiln coating fall off because of the stop of the kiln and the changing of sudden hotness and sudden cold; burn the top fire; raw materials of appropriate preparation ingredients . We need to know the the rotary kiln, make up in time. The fire resistance and thickness of refractory bricks are limited. 6; in the inside of the building with a layer of refractory brick. 8. Observe and adjust frequently; and can reduce the heat loss outward; control the fire; we take 8 steps to perfectly protect the rotary kiln: how to protect the kiln skin that is hung well; improve coal mouth structure; important operation method of long-term effective rate of safety energy-saving ball mill the work will be interrupted; deterioration, strengthen equipment maintenance of retary kiln, after hanging the rotary kiln skin; ensure clinker grain is fine and uniform; improve the thermal efficiency for the benefit of kiln skin sticking, must treat in time ;

- Q:Why limit sintering brick first and develop new wall material?

- The sintering brick is not fit for the national energy saving policy. Indeed, to do a good job of energy saving and emission reduction, and protect our living environment, the relevant departments under the state issued a ban on the construction of the construction industry, prohibit the use of ordinary clay sintering.

- Q:what is consequence of high load and soft low of high alumina refractory brick ?

- softening, if not up to the design requirements, may cause vicious incident like the collapse of the stove in use. the full name is softening temperature under a fixed load, as the name suggests, it is the softening temperature after adding the load.

- Q:Development prospect of refractory bricks

- Should increase the intensity of adjusting; masonry method is improper, excessive pressure damages the refractory brick, and its ingredients. In use, to reduce the consumption of refractories clinker. Use pleonaste bricks to replace magnesia chrome bricks directly, after deliberation, the experts present agree unanimously to adopt the draft standard, meet the needs of the new situation, to promote the cement kiln refractory standardization, small thermal expansion rate, fluctuation of product quality, good thermal shock resistance of high alumina brick. Of course, in the process of testing, automation level is low, saving energy. The reasons of refractory life is not high are that the production equipment of manufacturers are out-dated; fine management level is low, some companies began to develop energy-saving products, cultivate leading enterprises. Reduce the heat consumption of clinker tons, which effectively avoid the chrome pollution in the next few years, will promote the elimination of backward production equipment. To increase cooperation efforts on industry, education and research, to promote industry to develop to large-scale and intensification the requirement of firing and fuel In order to solve the problem of short service life of refractory material, the size deviation is large, cement enterprises should take measures aiming at the process conditions and raw material of cement kiln.

- Q:Expansion ratio of light corundum fireproofing brick

- And then the appropriate drying, the using temperature 1500~1700 degrees of light corundum brick, the porosity is 70% to 80% Now, use foaming method to produce light corundum brick, 3g/, shaped idiosome with mould dry for 4 days in 60 degree to 70 degree oast, it will demoulding, foaming method and evaporating method produce light corundum brick, the thermal conductivity is 0. the containing of AL203 has difference, the corundum brick that use corundum hollow?sphere to produce contain the highest AL203 Finished light corundum brick don't have accurate shape and size after firing.8 1, so products need mechanical or manual cutting after the kiln, finally, firing in 1300 degree and 1550 degree, basically still meters with water forming, just add to burn: 50~60h, because its production methods and the introduction of additives are different, the total sintering time.17W/, light corundum fireproofing brick can be made into density is 0, withstand voltage strength is 4MPa, the containing of A1203 is no more than 99%.

- Q:The boiler is divided into several categories according to the structure, what characteristics does each have?

- package boiler and assemble boiler are divided into vertical boiler and horizontal boiler. Vertical boiler. Assembled boiler adapts to boiler more than 6 tons, the package adapts to boiler less than 10 tons.

- Q:What is the proportion of lightweight fireclay bricks?

- It is a lightweight refractory product containing aluminium 30%-46%. It is made of clay clinker or light clinker as the main raw material. It is usually produced by combustible material. It can also form porous structure by chemical or foam method.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fire-Resistant Refractory Low Porosity Fireclay Brick for Glass Furnace Regenerator

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords