Ferro Silicon Origin In Henan Province CNBM China Fortune 500

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Usage

Ferro silicon is widely used in the steel making,iron casting ,low-carbon ferroalloy producing:

1 In the steel making field,Ferro silicon is used as deoxidizer and alloying agent to precipit and diffusedeoxidation.Adding a certain amount silicon of fe-si to the steel can obviously improve the strength ,hardness ,elasticity and permeability of steel.

2 In the iron casting,it is used as ball mile agent and alloying agent especially in the nodular iron casting, Adding ferrosilicon to cast iron ,it can prevent the formation of carbide and promote the precipitation of graphite and the nodulizing.then the mechanical capacity can be the same of steel's.

3 High-silicon ferrosilicon can be used for the production of the low-carbon reductant in ferro alloy industry.

4 In addition ,ferro silicon powder can be used as a suspended phase in the mineral processing industry and coatings for welding electrodes in the electrode manufactruing.

Application

Used as deoxidants and desulfurizing agents, and could purity the molten steel, etc. The size includes:0-3mm, 3-25mm,10-50mm, etc.

Packaging & Delivery

Packing Details: In 1 MT Jumbo Bags

Delivery Detai | Within 30 days after received the deposite |

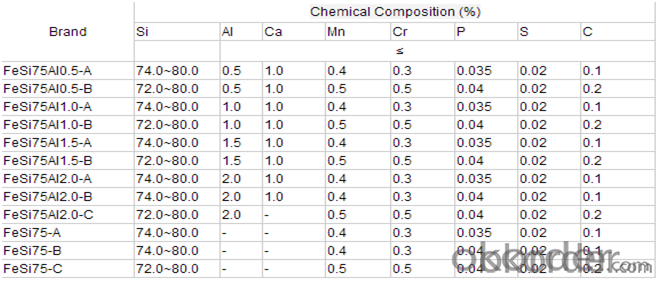

Specification

- Q:What type of carbide is the most ductile?

- Cemented carbide material with tungsten and cobalt carbide toughness is better, at present the carbide grade in the most toughness of YG15. The relation between cobalt content and toughness is shown below. It can be seen that cobalt content and 13%-16% toughness are the best. In this interval, only YG15 cobalt content is 15%.

- Q:What materials are hard alloys used to process?

- YG hard alloy, impact resistance, high temperature resistant, processing pig iron.

- Q:How hard metal is welded with stainless steel?

- Oxyacetylene brazing, using copper wire dipped in copper flux, brazing carbide and stainless steel.

- Q:Carbide and carbon steel

- Carbon steel is a relatively traditional black metal material, according to the carbon content, nature, use, there are many categories. Carbon steels contain almost no alloying elements (except trace elements such as silicon, sulfur, phosphorus, etc.) during smelting. Carbon steel can be used for many daily purposes.Cemented carbide is a relatively new powder metallurgy material developed in recent years. The finish of the cemented carbide products is very high, even higher than that of ordinary quenched steel. Therefore, a machining tool that is often used as ferrous metal.

- Q:What are the differences between the two grades of carbide, YT15 and YT5?

- YT5 is often used for roughing or machining, impact cutting, and YT15 is usually semi finishing and finishing.

- Q:Compare the advantages and disadvantages of high speed steel and cemented carbide

- Hard alloy powder is: high hardness metal carbide to micron order, with cobalt, molybdenum, nickel and other binder, under high temperature and high pressure sintering temperature. The carbide content in hard alloy than high-speed steel, high hardness, good abrasion resistance (HRC75--80).Hard alloy red hardness can reach 800-1000 degrees.Carbide cutting speed is 4 - 7 times higher than that of high speed steel, and cutting efficiency is highThe disadvantage is that the bending strength is low, the impact toughness is poor, the brittleness is great, and the impact and vibration resistance are low

- Q:Can CBN wheels grind cemented carbide? Why?

- Tungsten carbide and non-metallic ceramic materials are usually made of diamond grinding wheels.CBN can iron group elements of workpiece.According to the development trend of ordinary abrasive abrasive, > superhard abrasiveCorundum like A - >CBN BSilicon carbide C> diamond DThe rule: A sends to B, C develops D

- Q:What's the use of recycling cemented carbide?

- Recycling can be reused ah, and recycling plastics, scrap iron and so on are a reason.

- Q:What is the hardness of cemented carbide?

- Different grades, different hardness, usually (86 ~ 93HRA, equivalent to 69 ~ 81HRC);

- Q:Hard alloy is tungsten?

- Tungsten, titanium, tantalum (niobium) carbidesIs the main component of tungsten carbide, titanium carbide, tantalum carbide (or niobium carbide) and cobalt. This kind of hard alloy is also called universal cemented carbide or universal hard alloy.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ferro Silicon Origin In Henan Province CNBM China Fortune 500

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords