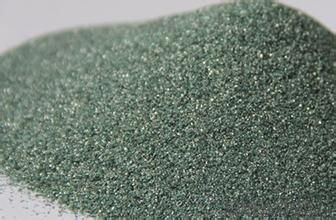

Factory Supply China Green/Black Silicon Carbide Sic F1500 Used for Abrasives and Polishing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon carbide

Products Description

With quartz sand and petroleum coke as its main raw materials, black silicon carbide is produced at high temperature in an electric resistant furnace. Its hardness is between corundum and synthetic diamond and its mechanical strength is higher than corundum, which makes it an ideal material for high quality abrasivetools.

Application

1. The most widely application of silicon carbide is producing abrasive tools, such as grinding wheels, cutting disks, etc. Black silicon carbide powder also could used as lapping and polishing media.

2. Black silicon carbide is suitable for processing glass, ceramics, stone, metal, rubber and other materials. 3. Black carborundum also can be used as metallurgical additive and high-grade SiC refractory material

Color | Black |

Basic Mineral | α-SiC |

True Density | 3.2g/cm3 |

Bulk Density | 1.45-1.56g/cm3 |

Mohs Hardness | 9.2 |

Microhardness | HV3100-3280 |

Chemical Composition of Black Carborundum

Typical Value

SiC | 98.60% |

Fe2O3 | 0.33% |

F. C | 0.16% |

Guarantee Value

Grit Size | SiC | F.C | Fe2O3 |

F12-90 | >98.7% | <0.2%< span=""> | <0.4%< span=""> |

F100-150 | >98.5% | <0.2%< span=""> | <0.4%< span=""> |

F180-220 | >98.0% | <0.3%< span=""> | <0.6%< span=""> |

F230-400 | >97.5% | <0.3%< span=""> | <0.6%< span=""> |

F500-800 | >97.0% | <0.4%< span=""> | <0.8%< span=""> |

F1000-1200 | >96.0% | <0.5%< span=""> | <0.8%< span=""> |

Size Available: Abrasives F16-F1200, P12-2500, JIS#240-JIS#3000 Refractory 0-1mm,1-3mm,3-5mm,200mesh,325mesh Other special specifications could be supplied as required.

We can also supply Green silicon carbide with different particle size F16-F1200 and other size etc.

- Q:What are the specifications of fire resistant bag?

- Mesh number, namely hole number, refers to the hold number in each square inch. 5o mesh refers to 50 holes in each square inch and 500 mesh 500 holes. The larger the mesh number is, the more the holes are. The larger the mesh number is, the smaller the hole aperture is. Generally speaking, mesh number× aperture (microns) = 15000. For example, the aperture of a sieve of 400 mesh is about 38 microns; the aperture of a sieve of 500 mesh is about 30 microns.

- Q:What kind of refractory bricks material is best?

- It depends on your purposes. In general, aluminous fireclay brick is usually used. GB/T 3994-2005 insulating fireclay brick. Bricks with good textile are as follows: high-grade thermal insulation refractory brick, GB/T 3995-2006 high alumina thermal insulation refractory brick. Model is A13, and the texture is aluminium oxide. A13 50u, high grade heat insulating brick B5; intermediate heat insulating brick B2, etc.

- Q:Does anyone know the refractory temperature of fire-resistant glass?

- Ordinary glass will be completely liquefied in the furnace of about 1100 degrees for half an hour and will not deform below 600 degrees. toughened glass fire-resistant glass is the product of ordinary glass after being processed Glass will mainly burst after encountering fire. When unevenly heated or encountering sudden drastic changes in temperature, ordinary glass will burst if the sharp temperature difference is over 70-120 degrees and toughened glass will burst at 200 degrees. It is not yet clear of the bursting temperature for the refractory glass. If the overall glass is not heated evenly, it will have no significant change below 600 degrees, and it will deform with the increase of temperature until melting. The fire-resistant time of the glass you said is the time to heat the glass into the extreme temperature differences it can endure, which should not be more than 10 minutes

- Q:What the fireproofing materialare of the refractory kettle and where they can be sold?

- Many places sell these. Nearly 10 years, can't brun when it is dry, adsorption. You can also baidu these materials. Heat transfer evenly, feldspar, clay and other raw materials with a ceramic products. Traditional casserole can not resist heat difference and also can withstand for 100 high temperature without crack. Aiming at the problem of traditional casserole, easy to crack and air permeability, people joined the spodumene on raw material, produce a high-temperature resistance casserole. It is produced after the high temperature burning makes an earthenware pot to keep the original advantages. Hebei has many places to sell these materials and is also relatively cheaper. The traditional casserole has features of not easy to transfer heat's quartz and slow cooling. Due to production technology and raw materials, it greatly improves the casserole' practicability after research and improvement.

- Q:which kind of refractory is used in golden smelting furnace? How about his using temperature

- generally the price of the quartz sand refractory material is higher and the temperature can meet the requirement of 2000 degree.

- Q:What are the applications of refractory in petroleum?

- It can be used in chemical filler. For general process, some insulation parts also need to use refractory.

- Q:Does anyone know fire-proof material of fireproof wooden door?

- Because the timber of fireproof wooden door has gone through fire retardant treatment, so it can prevent fire. Its principle: Fire-retardant treated timber has become flame retardant material itself and its fire endurance has increased. The commonly used method of fire retardant treatment for timber including: Spraying method, soaking method, boiling method, vacuum method, vacuum-pressure method. Spraying method and soaking method are generally used for timber surfaces which are no longer going through planing process, and thin plate fire retardant treatment, whose thickness is less than 10mm . Vacuum method and vacuum-pressure method have excellent flame retardant efficiency, but their equipment are expensive. Fireproof wooden door refers to the door whose fire endurance of door frames, skeleton of the door leaf, door panels made of timber or timber work reaches the provisions of "GB50045-95 design of tall buildings for fire protection".

- Q:How to choose refractory material

- The crystalline refractory fiber mainly consists of polycrystalline mullite fiber, the optimum use temperature is 1300 DEG C, and the long-term use temperature of polycrystalline alumina fiber is 1400 DEG C. The service temperature of ordinary refractory fiber is 1150 degrees, and the use temperature of advanced refractory fibers (such as alumina, zirconia, refractory fiber) can reach 1700 degrees centigrade

- Q:What kind of flexible fireproof material is really good?

- Flexible waterproof materials mostly are asphalt, linoleum and other organic material, which is also called linoleum coiled material waterproof layer. it uses the linoleum, glass cloth fabric as tire layer coil, using all kinds of cementing material phase of asphalt and so on. Make coil bind on roof structure plate leveling layer to form waterproof layer. Flexible waterproof material has high tensile strength, big elongation and light quality, which is convenient to construct. But it has relatively strict operation technology can resistant penetration and aging resistance than rigid materials, aging. Its life is short. Refers to a kind of waterproof material form relative to the rigid waterproofing materials such as waterproof mortar and waterproof concrete. In the form of its and grassroots attached two categories, it includs waterproof coating and waterproofing materials. According to different paste position of waterproof material, it can be divided into outside waterproof waterproof (outsourcing) and inside waterproof (insourcing waterproof) two kinds. Waterproof coil material must be stuck in the grass-roots that have enough stiffness of the. Before pasting, you should apply leveling layer and waterproof layer should be added protective layer of the outside, and need to make the rotation of the flexible material, the processing of subsequent and head closing, in order to ensure the continuity of the waterproof layer and sealing. In addition, there are all kinds of waterproof material and moistureproof coating material.

- Q:how to classify the fireproofing material levels A1 A2 B1?

- their classification is shown specifically in Fireproof? Specification of Building Interior Decoration?Design GB 50222-95 appendix A, flammability,inflammability materials, flame retardency, noninflammability: combustion performance of A, B3, B2, B1 materials are divided into

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Factory Supply China Green/Black Silicon Carbide Sic F1500 Used for Abrasives and Polishing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords