Factory Prices PVC Ciling For Interior Decoration

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

factory prices pvc ceiling for interior decoration:

Standard size: 595*595mm

Thickness: 7, 7.5, 8, 8.5, 9,9.5mm

Easy Install

Product Applications:

PVC gypsum ceiling tiles is produced with PVC laminated and aluminum foil on back, it is fire-proof, water-proof, antisepsis and heat insulation

PVC Ceiling Tiles Specification:

Standard size: 600*600mm, 600*1200mm

Thickness: 7mm, 7.5mm, 8mm, 8.5mm, 9mm, 9.5mm.

Size tolerance: Length ± 2mm, width ± 2mm, thickness: ± 0.5mm

Weight: 6-7.5kg/sqm

Strength: More than 160N.

Supply ability: 30, 000 Square meter per day.

Package: Shrink plastic bags and cartons,usually packing as 8 PCS/CTN or 10 PCS/CTN.

Product Advantages:

(1) Inside plaster board with one side vinyl PVC facing and backside with aluminium foil;

(2) Relevant accessories of galvanized steel Tee Bar keels to PVC ceiling board include as follows:

Main keel 32x24x0.30x3600mm

Height32mm/Width24mm

Thickness: 0.30mm

Length: 3600mm,

Cross keel 26x24x0.30x1200mm,

Small cross tee 26x24x0.30x600mm,

Side keel(angle) 22x22x0.40x3000mm.

Main Product Features:

As a manufacturer of gypsum board in China, we own ourselves the selling system, including the domestic market and foreign market. Our product's quality improves steadily, and it is extensively recognized by the domestic and the oversea markets such as America, Japan, Australia, Philippine, New Zealand, Middle East, Panama, India and so on.

If you are interested in our company and our products, please directly tell us what kinds of gypsum board you are interested in and the specification, so we can calculate how to pack in the container and the exact price for you.

What we can assure is our quality is high, with best service as well.

If something unclear or some questions, you can contact us at anytime you want, we will try our best to let you know our company and our products well.

Welcome to visit our factory. Thank you.

And hope we can cooperate.

Thanks for your support of our work and hope to have long term cooperation with you.

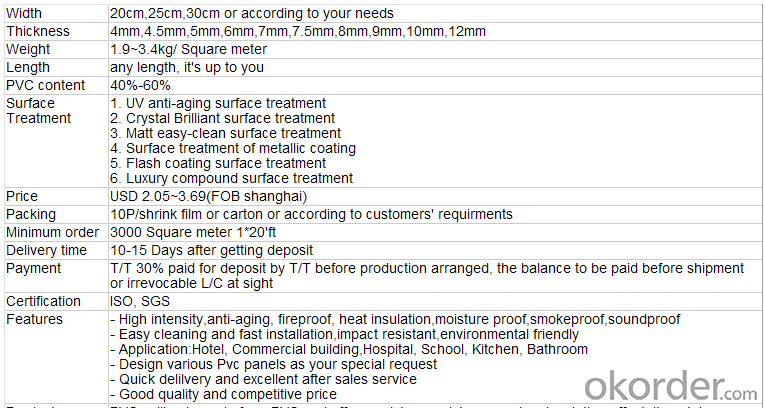

Product Specifications:

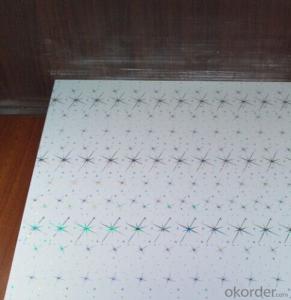

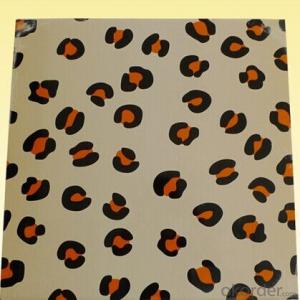

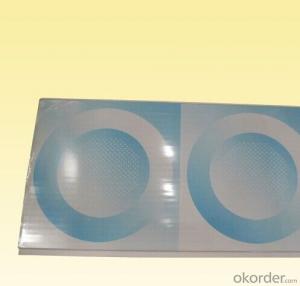

Images:

- Q:What is the treatment before the color, what kind of paint or paint to color? Satisfied with points

- Spray gun can be directly spray.

- Q:PVC door cut how bad repair

- PVC door repair has a special fill ash putty, make a good gray after the polished smooth And then use the same color paint spray paint treatment Generally more well-known brands will have material processing

- Q:Has anyone tried this? I need to use it for a window that is 8'4 wide and due to the construction of the ceiling (concrete) and window frame (metal) I can't put in any center support. What diameter pipe did you use and what is the width of the window you used it on? Any tips/tricks?

- You could try 1 1/2 or 2 pvc, but even that size of pipe might bend slightly under the weight of the drapes. The 2 is probably too large for any drapery rings. I am not sure if 1 1/2 is too large for rings or not. You could also consider using electoral schedule 40 1 1/2 piping/ But if you want to use thinner pipe, then you might consider either black pipe (used for natural gas) or galvanized pipe. This is much heaver but will be as strong if not stronger than PVC piping. But it will also weigh a lot more.

- Q:What is the best glue on the PVC board glue?

- Pvc special glue, hard and soft different

- Q:What is the difference between PVC board and PC board?

- Material is different, its mechanical properties are different, PVC is PVC, PC is polycarbonate.

- Q:Pvc board how to paint? With the general way of painting in the pvc board spray paint spray uneven, which know friends told me, his home to buy a few pvc board to do the closet, but how the experimental spray spray do not understand. Polyvinyl chloride material

- Spray the way, if it is pvc, then it is not too suitable, because that way, then pvc translucent no, you can find professional spray paint, the best institutions, because they have paint room, so spray can, Otherwise artificial to do, it is difficult to achieve good results

- Q:What is the difference between pvc plastic flooring and composite flooring? The

- PVC floor environmental protection. Wearable. Material really. Unlike the wooden floor flower head more. Easy to be fooled.

- Q:Pvc floor and floor leather is the same?

- PVC flooring is a composite material, the thickness is very thick, the floor leather is a soft PVC products, not durable, not wear

- Q:How thick is the pvc board?

- Hardness PVC board: has good chemical stability, corrosion resistance, hardness, strength, high strength, anti-ultraviolet (anti-aging), fire-retardant (with self-extinguishing), reliable insulation, smooth surface smooth, not Absorbent, no deformation, easy processing and so on. The product is excellent thermoforming material, can replace part of the stainless steel and other corrosion-resistant synthetic materials, is widely used in chemical industry, oil, electroplating, water purification equipment, environmental protection equipment, mining, medicine, electronics, communications and decoration industries The Product thickness: 0.8-30mm Product width: 1300mm 1500 mm Accessories processing: PVC processing parts Reed can be produced according to customer needs, can be hot-rolled, hot, CNC, and so on. PVC soft board: laminated sheet: 2-60mm Product width: 1000mm × 2000 mm PVC transparent board: high-strength, high transparent plastic sheet, the product color is white, sapphire blue, brown, brown and other varieties. The product is high strength, high transparency, good weather resistance, non-toxic, health, physical properties better than plexiglass. Widely used in equipment protection board, interior, drinking water tank, liquid level display. Product thickness: 2-20mm Maximum width of products: 1300mm Product Length: 100-10000mm Recommended Specifications: 1300 × 2000mm PVC soft board (coil): surface gloss, soft. There are brown, green, white, gray and other colors to choose from, the product material, fine production, widely used. Features Soft and cold, wear, acid, alkali, corrosion resistance, excellent tear resistance, with excellent weldability, physical properties than rubber and other coil. Used in chemical, electroplating, electrolytic cell lining, insulation cushion, trains, automotive interiors and auxiliary materials.

- Q:I'm installing a computer and have to drop both power and Ethernet from the ceiling. Will i get interference running the 2 wires close together?

- The National Electric Code does not permit power and low voltage conductors such as network cabling to be run in the same conduit. That being said there are dual channel power and data raceways that can be legally used for your application. As far as interference goes, technically you should run network cabling at 90 degree angles to power cabling. However many installations get away with short distance parallel runs to low amperage power cables without any adverse affects. Good Luck...

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Factory Prices PVC Ciling For Interior Decoration

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords