factory direct sales auto-feeding lazer engraver

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Syntec control system

2.9.0kw ai cooling spindle

3.Janpan Servo motor

4.Taiwan Hinwin rail

5.Vacuum table

Professional muti-function cnc engraving machine 1325

Main technical parameter

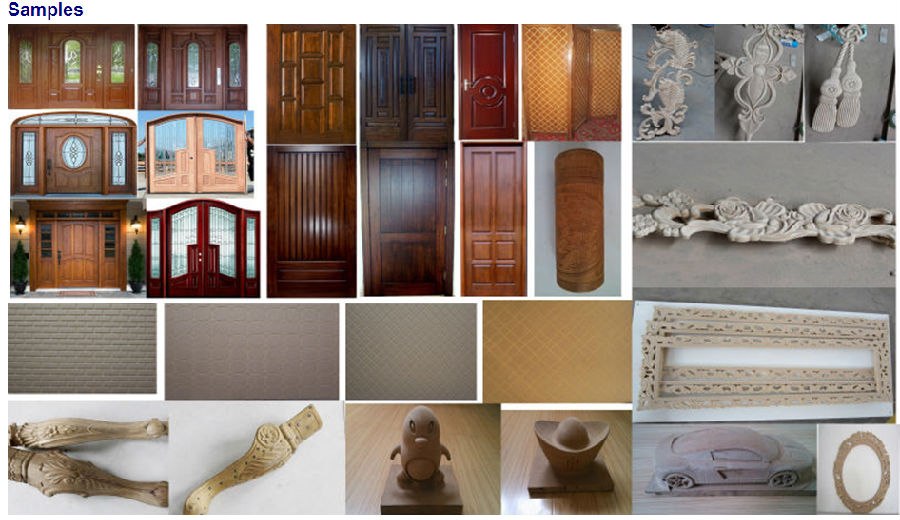

It can be used in carving on waved board, furniture door, arts door, paint free door, screen door and kinds of furniture.

Machine Size Work Envelope Repositioning Resolution Resolution Power Of Spindle Spindle Speed Max.Speed Max.Cutting Speed Bridge Clearance Control System Working Voltage Command Code | 2100×3500mm 1300×2500mm +0.02mm +0.001mm 9kw 0-18000(24000)rpm/Min 60000mm/Min 25000mm/Min 400mm SYNTEC control system AC380V/50Hz HPGL\G |

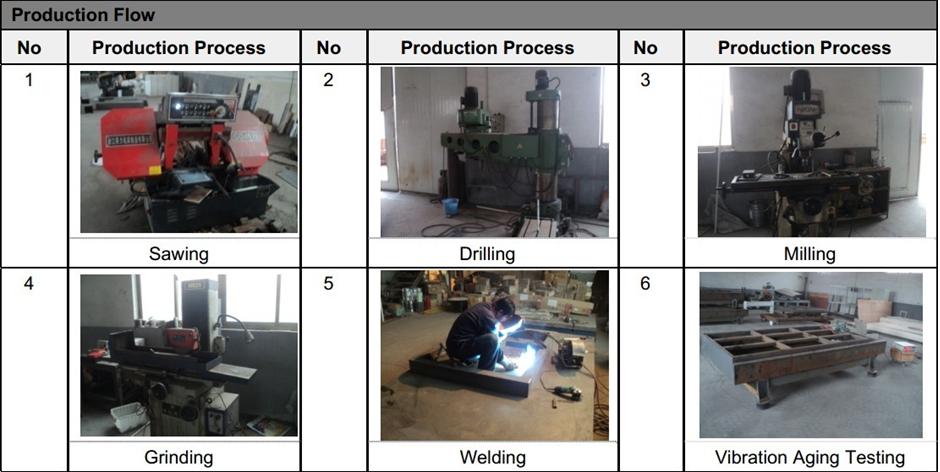

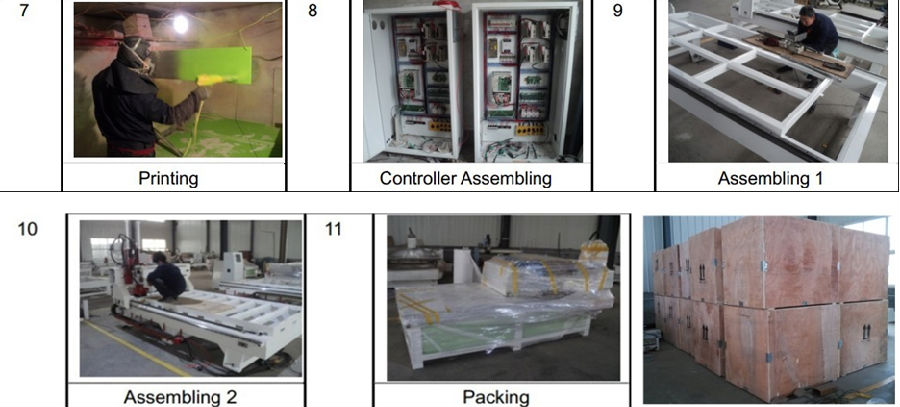

Machinery Characteristics:

Stable Structure: Square steel formed frame, stable and can not be deformed.

Perfect Parts: Imported Taiwan control system;AMT Line guide rail maid in Taiwan, due-row, four line ball slider, heavy loading and steady proceeding, German made ball lead screw with accurate cutting, Japan Servo Control system

Italy spindle motors.

l Good parts: The drive is more powerful: the use of well-known brands stepper motor,

become more powerful

l Armless automatic tool change system;magazine capacity 8(optional)

l High adhesion vacuum suction device;Displacement up to 230 cubic meters / hour

l Open software interface,.Excellent compatibility compatible of TYP3/ARTCAM/CASTMATE/WEITAI and other CAD/CAM design software Ensure that the design no problem.

- Q:Three procedures woodworking engraving machine and single head woodworking engraving machine distinction

- Machine hardware: hardware parts, there will be corresponding changes (these speak up some complicated, customers can study), because the processing head is not the same.

- Q:Which engraving machine is better in Northeast China? We feel how quanta force woodworking engraving machine?

- Customers buy machines also want to worry about, our machines are of good quality and good service, in all parts of the country have agent point, after-sales service is convenient

- Q:Can woodworking engraving machines carve stones?

- In theory, it is not possible, because they use different tools to carve wood and carve stones.

- Q:How to deal with the dust of woodworking engraving machine?

- Many customers in woodworking engraving machine, if there is no dust, or no dust, will bring some harm to the machine and people! To fundamentally eliminate dust pollution, we must take the comprehensive management of the line, starting from the production equipment, the use of advanced and rational mechanical equipment, supplemented by a certain dust, dust removal measures. But in the current conditions, the most effective measure is to choose dust removal equipment. The selection of dust removal equipment should take into consideration the degree of purification required and the nature of the dust. For large wood dust and medium-sized wood dust can be collected in a timely manner, and for the most serious kinds of fine wood dust, the traditional effective way is to use pneumatic dust collector or bag dust collection equipment to collect.

- Q:A woodworking engraving machine can engrave anything

- That's not the truth。First, woodworking engraving machine engraving machine is divided into planar and three-dimensional engraving machine, the door is flat, chair legs is three-dimensional, with different engraving machine carving, of course, some models are either flat or carved carved, three-dimensional, such as Shenyang engraving machine processing center the company has several such models.

- Q:Woodworking engraving machine, how to engrave the double curved arc?

- There's no other way to break it!

- Q:What lubrication methods are used in woodworking engraving machines?

- If the rack machine, X, Y, centralized lubrication Z three axis guide, if the screw machine in addition to rail lubrication, X, Y, Z three screw with concentrated lubrication, centralized supply generally has two types of manual and electric, used lubricating oil for lubricating oil.

- Q:Woodworking engraving machine installation process, machine test method

- Engraving machine use environmentEngraving machine for high-tech mechanical and electrical integration equipment, the work environment has certain requirements.1., avoid strong current, strong magnetic and other serious impact engraving machine signal transmission equipment. Such as: welding machine, tower and so on.2. use three core power supply to ensure the good grounding of the engraving machine and reduce the interference.3. voltage requirements are stable, avoid large fluctuations, it is best to use voltage regulators.4. machines should not work long hours in a strong acid or alkali environment.

- Q:How to set the path attribute of woodworking engraving machine?

- When processing the open path attributes switch can be processed in accordance with the "path with parameters, but in the beginning and try cutting processing, should be closed" feed "switch, set a low feed speed cut.Such a speed is very important, customers must pay attention to settings. Therefore, customers must pay attention to the "path property" setting before using woodworking engraving machines.

- Q:How can we eliminate the limit alarm of woodworking engraving machine? Is there any way?

- One possibility is that the I/Q window state parameters under the disorder, it is need to change, click on the X axis and press ctrl+shift+alt and then right-click pop-up window click "reverse the polarity", click on the Y axis and press ctrl+shift+alt and then right-click pop-up window click "reverse the polarity", click on the Z axis at the same time ctrl+shift+alt left click the pop-up window click "reverse the polarity";

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

factory direct sales auto-feeding lazer engraver

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products