Endless PVC and PU Conveyor Belt With Jointing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Duty Endless PVC and PU Conveyor Belt With Jointing

PVC & PU Conveyor Belt

PVC conveyor belt in flexible construction provides high strength,low stretch characteristics, dimensional stability & are totally resistance to moisture, rot & mildew.

PVC Conveyor belt uses polyester fabrics as reinforcing materials, mainly used for conveying light, medium quality materials, suitable for use on the conveyor systems.

Material: PU,Shape: plain (flat surface),Thickness: 1mm

Specifications: one ply fabric-one ply PU

Tensile strength: >150N/mm

Temperature range: -10°C~+90°C

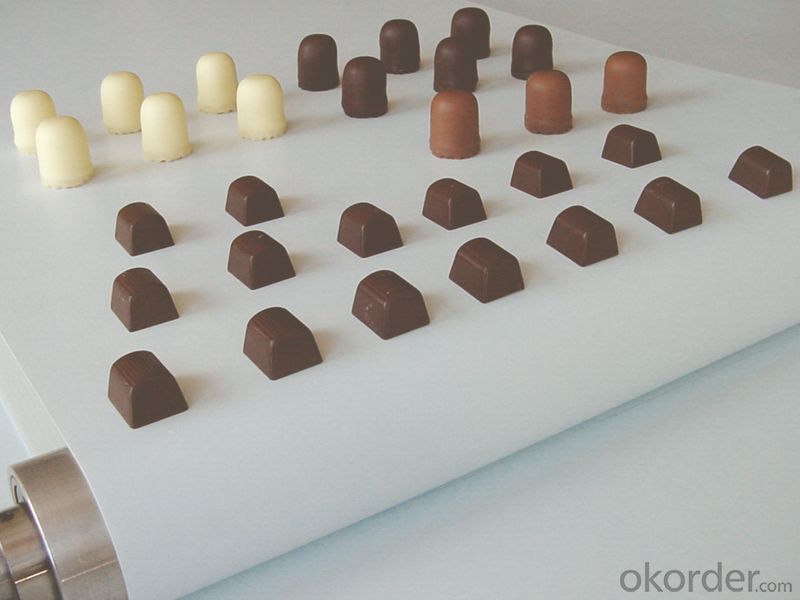

Color: white

Applications: conveyance and production assembly lines in the areas of cigarettes, foodstuffs, electronics, pharmaceuticals, drinks and papermaking Specification.

Conveyor belt fabric layers:

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

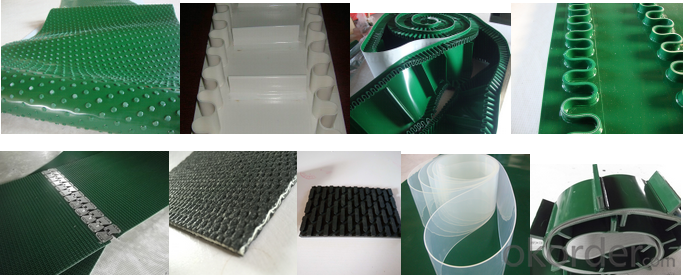

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

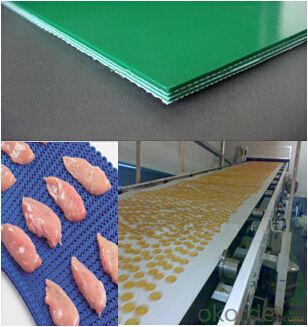

PVC: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines belt.

PU: Most applicable to the food industry and other industries .

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

Packaging & Shipping

1.Free for samples, Door-to-Door.

2. By Air or by Sea for batch goods, Airport/ Port receiving.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:Based on customers' quantity. In general,25 days for batch goods.

Product Pictures:

Our Company:

Pls contact me freely if any inquiry,thank you!

- Q:How do I maintain an olive net?

- To maintain an olive net, you should regularly inspect it for any damage or tears. If you notice any holes, repair them promptly to prevent birds or other pests from getting through. Additionally, ensure that the net is properly secured to avoid any sagging or gaps. It's also essential to remove any fallen olives or debris from the net regularly to prevent it from weighing down or causing damage. Finally, store the olive net properly when not in use to prolong its lifespan.

- Q:Can olive nets be used on olive trees grown in vertical gardens?

- Yes, olive nets can be used on olive trees grown in vertical gardens. Olive nets are commonly used to protect the olive fruits from birds and other animals. Whether the olive tree is grown in a traditional orchard or a vertical garden, the nets can be installed to ensure the crop's protection.

- Q:Can olive nets be used to protect against wind damage?

- No, olive nets are primarily used to protect olive trees from birds, not wind damage.

- Q:Plastic products in the injection process should pay attention to what?

- Plastic thermoplastic plastic molding process because of the presence of the crystalline volume changes shape, inner stress, frozen in plastic residual stress in the large, strong molecular orientation and other factors, so compared with thermosetting plastic shrinkage shrinkage is large, wide range, obvious direction, also after molding the shrinkage, annealing or conditioning after shrinkage generally than thermosetting plastic.

- Q:How do you secure an olive net to the ground?

- One effective way to secure an olive net to the ground is by using anchor pins or stakes. These can be inserted into the ground around the perimeter of the net and then hammered down to ensure a secure hold. Additionally, using weights or rocks along the edges of the net can help keep it in place and prevent it from being blown away by wind or other factors.

- Q:Can olive nets be used for different varieties of olives?

- Yes, olive nets can be used for different varieties of olives. Olive nets are designed to capture the falling olives during harvest, regardless of their variety. They provide a convenient and efficient method for collecting olives from various types of olive trees.

- Q:Can olive nets be used in small backyard olive trees?

- Yes, olive nets can be used in small backyard olive trees to protect the harvested olives from birds and other pests.

- Q:White plastic products used for a long time will be yellow, how to do?

- Plastic products aging, color will increase, yellowing of plastic products can no longer be white.

- Q:Can olive nets be used in organic certification processes?

- Yes, olive nets can be used in organic certification processes. Olive nets are commonly used in organic farming practices to protect olive trees from pests and to collect fallen olives during harvesting. These nets are made from natural and biodegradable materials, aligning with the principles of organic farming. Therefore, they can be used in organic certification processes without any issues.

- Q:Can olive nets be used on large-scale olive orchards?

- Yes, olive nets can be used on large-scale olive orchards. Olive nets are commonly used in commercial olive farming to protect the harvested olives from falling on the ground, reducing losses and ensuring higher yields. These nets can be spread over the entire orchard, effectively catching the olives as they are mechanically harvested or shaken from the trees. The use of olive nets on large-scale olive orchards is an efficient method to optimize production and maintain the quality of the harvested olives.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Endless PVC and PU Conveyor Belt With Jointing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords