Electroytic Tinplate Sheet SPTE ETP for Packaging Foodstuffs Beverages

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Electroytic Tinplate Sheet SPTE ETP for Packaging Foodstuffs Beverages

Tinplate has a beautiful metallic luster as well as excellent properties in corrosion resistance and paint-ability.

Available Specifications and Sizes

| Steel Type | MR, SPCC |

| Temper (BA&CA) | T1~T5, DR8~DR10 |

| Coating | 1.1~11.2g/㎡ |

| Thickness & Tolerance | 0.15~0.5mm (Tolerance: ±0.01mm) |

| Width & Tolerance | 600~1010mm (Tolerance: +2/-0mm) |

| I.D | 508 mm |

| Coil Weight | 3~10 MT |

| Passivation | 311 |

| Oiling | DOS |

| Surface Finish | Bright, Stone, Silver, Matte, (B, R, R2, S, S1, S2, M) |

| Quantity for 20 Feet FCL | 20~25 Tons |

| Package | Seaworthy Export Standard Wooden Pallet |

Special specifications are available on customers' requirements

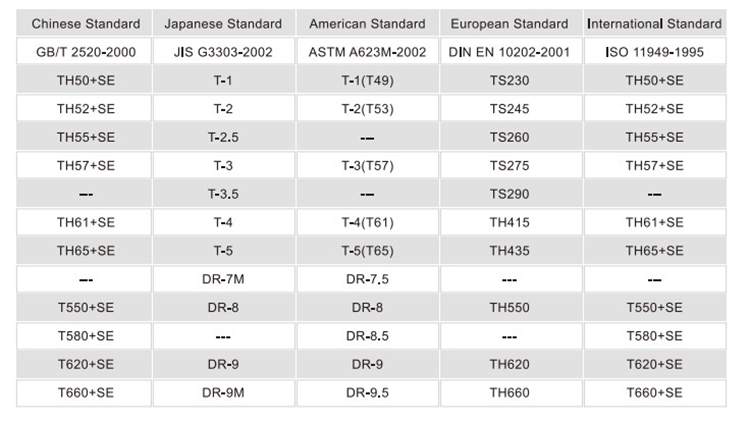

Standard Comparison for Temper

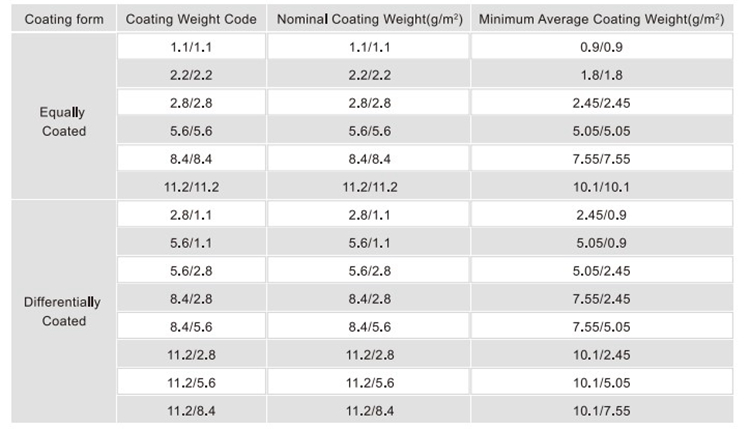

Tin coating weight

1.ETP

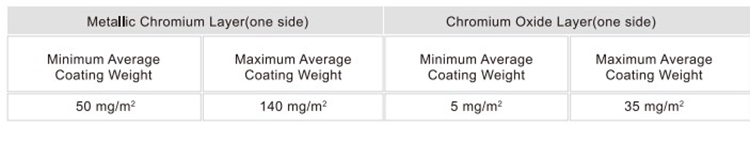

2.TFS

Applications of Tinplate and TFS: Consumer Packaging and Industrial Packaging

| TINPLATE | ETP is primarily used for packaging foodstuffs and beverages, but it is also used in containers for oils, grease, paints, polishes, chemicals and many other products. Aerosol containers,caps and closures are also made from ETP. |

| TFS | TFS are most frequently used for can tops, screws and lug caps, snap and press-on closures and shallow-drawn food cans. |

Miscellaneous

| in Electronics | Electrodes, Cable tape, Magnetic screen covers, etc. |

| in Engineering | Automotive oil filters. Automotive air filters, Gaskets, etc. |

| in Construction | Gas meter internal components, Heat exchangers, cookware, shelving, etc. |

Package

- Q:What are the advantages of tin packaging?

- Mature technology and high production efficiency: the production of tinplate has a long history, has a mature skill set of production equipment with matching, high production efficiency, can meet a variety of product packaging needs.

- Q:How is tinplate coated for pharmaceutical packaging?

- Tinplate is coated for pharmaceutical packaging by applying a thin layer of protective lacquer or enamel onto the surface. This coating acts as a barrier, preventing direct contact between the metal and the pharmaceutical product, ensuring its safety and integrity.

- Q:How is tinplate coated?

- Tinplate is coated through a process called electrolytic tinning. In this process, a thin layer of tin is electroplated onto the surface of steel sheets or strips. The steel is immersed in an electrolyte bath containing tin salts, and an electric current is passed through the bath. This causes the tin to deposit onto the steel surface, creating a protective coating that prevents corrosion and enhances the appearance of the tinplate.

- Q:What are the common surface finishes for tinplate?

- The common surface finishes for tinplate include bright, stone, silver, and matte finishes.

- Q:How does tinplate contribute to the protection of agricultural products?

- Tinplate contributes to the protection of agricultural products by providing a durable and corrosion-resistant packaging material. It helps to prevent contamination, moisture, and oxygen from reaching the products, ensuring their freshness and quality. Additionally, tinplate's ability to withstand extreme temperatures and physical damage further safeguards agricultural goods during storage and transportation.

- Q:Can tinplate be painted or coated with other materials?

- Yes, tinplate can be painted or coated with other materials.

- Q:What are the main factors affecting tinplate market growth?

- The main factors affecting tinplate market growth include the demand for packaged food and beverages, economic growth and industrialization, advancements in technology and packaging techniques, government regulations and policies, and the sustainability and recyclability of tinplate as a packaging material.

- Q:What are the main challenges in tinplate coil handling?

- The main challenges in tinplate coil handling include ensuring proper lifting and transportation techniques to avoid damage, managing the weight and size of the coils for safe handling, maintaining cleanliness to prevent contamination, and implementing efficient storage and inventory management systems. Additionally, coordinating with suppliers and customers to ensure timely delivery and minimizing transit damage are also significant challenges.

- Q:What are the common sizes and shapes of tinplate containers?

- Common sizes and shapes of tinplate containers include round cans, rectangular cans, and square cans. These containers can come in various sizes ranging from small tins for spices or cosmetics to larger tins for food products or industrial purposes.

- Q:How to prevent the corrosion of tinplate wall hydrogen sulfide blackening, expansion

- Oil pipelines and oil storage containers buried in the ground are exposed to the water, salt, alkali and acid substances directly in the soil, and they should be coated with antirust paint on the outside surface, and then sprayed with asphalt protection layer.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electroytic Tinplate Sheet SPTE ETP for Packaging Foodstuffs Beverages

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords