Diamond Shape Flat Cap Routel for Spider AT40

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

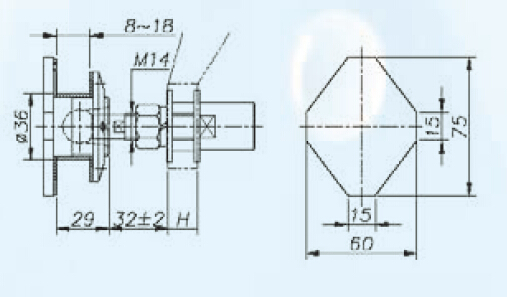

Product Name | Diamond Shape Flat Cap Routel for Spider AT40 |

Material | Stainless Steel 304/316. |

Finish | Natural |

Glass thickness | 8~18mm |

Bolt Size | M14 |

Max. axial bearing capacity | 4500N |

Max. Radial Bearing capacity | 2000N |

Adjustable angle | ±10 degree |

Min Order | 100piece/ pieces |

Packing | Inner Box + Carton Box |

Supply capacity | 100000 piece/ pieces per month |

Delivery time | 20~35 days after receipt of down payment |

Export market | Asia, America, Europe, Africa, markets. |

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Pictures:

Diamond Shape Flat Cap Routel for Spider AT40

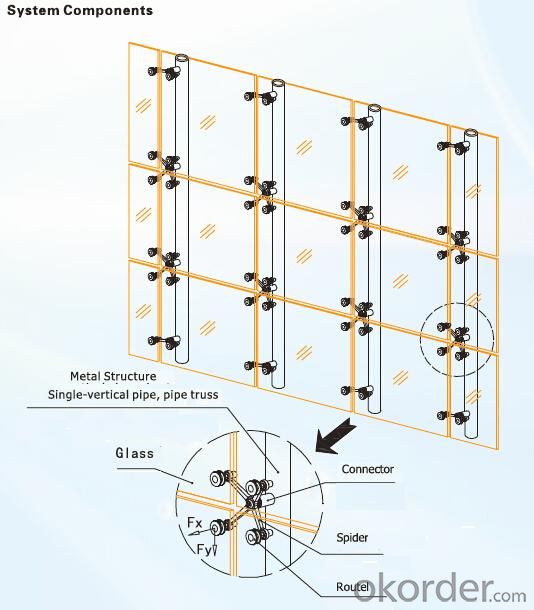

- Q:What is the point of the glass curtain wall and the whole hidden glass curtain wall?

- Full hidden glass curtain wall: full hidden curtain wall. Relative to the semi-hidden box (vertical and horizontal implicit; vertical implicit) in terms of. Curtain keel glass frame set all indoors. Curtain wall surface only glass glue. The appearance of simple and neat.

- Q:What are the specifications of the stainless steel jaws?

- A very common one. Use the same with the 200 splicing claws. Including glass area between 2.0m2 and 2.3m2, the thickness of 6 +6 or 8 +8 can be used. Thickness of 8 +8 is recommended to use 250 split claws, Jie Chen hardware.

- Q:What is the point of the ribbed curtain wall

- Is the whole glass curtain wall + split claws

- Q:Curtain wall decoration line junction how to take a good connection

- With a strong bond strength, crack resistance, anti-hanging, freeze-thaw resistance, waterproof and other effects. Easy to use.

- Q:Glass curtain wall claw should be how to calculate the size

- In general, our factory will be based on the customer's glass area and glass thickness, to advise customers to choose what specifications of the split jaws, common splicing claw specifications are: 150.160.200.220.250 and so on. Be sure to choose the appropriate type and specification of the splicing jaws so that both price and performance are guaranteed

- Q:Stainless steel splicing claws attached to what steel structure above

- Stainless steel splicing jaw pieces of the choice of models to see you mainly use the glass size, carrying the wind pressure, weight.

- Q:Do you want to glue when you install a splice?

- The point curtain wall is connected by a splice joint, a splice joint and a splicing jaw connection, a splicing claw and a support system.

- Q:The purpose and advantages of splicing claws

- The appearance of the glass curtain wall with the connection of the pawl is transparent, and the interior space and the outdoor environment are fused due to the lack of wall and good lighting. Split claws support structure and diverse, to meet the needs of different building structures and decorative effects. Splicing jaw pieces with spherical hinge connection, with the ability to absorb deformation, the security is also a great protection.

- Q:What is the meaning of the radial curtain of the glass curtain wall?

- Uses: Splicing claws in the glass curtain wall played a role in the convergence of the joints through the load to the steel structure or other body structure, its mechanical properties in this is particularly important. Performance Description: The use of splicing claws to connect the glass curtain wall transparent appearance, because no walls, good lighting, indoor space and outdoor environment can be integrated. Split claws support structure and diverse, to meet the needs of different building structures and decorative effects. Part of the split jaw pieces with spherical hinge connection, with the ability to absorb deformation, safety is also a great guarantee

- Q:Can the splicing jaw be welded to the stainless steel tube?

- Split claws support structure and diverse, to meet the needs of different building structures and decorative effects. Part of the split jaw pieces with spherical hinge connection, with the ability to absorb deformation, in the security also has a great protection.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Diamond Shape Flat Cap Routel for Spider AT40

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products