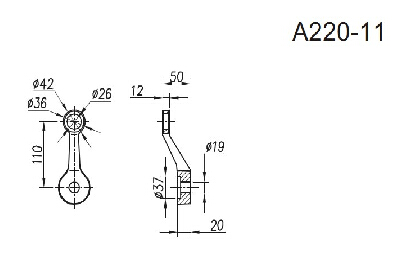

Curtain Wall System Short Single Arme Spider A220-11

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Name: Curtain Wall System Short Single Arm spider A220-11

Specifications

1. curtain wall spider system

2. made by casting

3. with genuine stainless steel

4. laser printing logo available

Table of Chemical Composition (%)

Material: S.S 304 | ||||||||

Carbon | Silicon | Manganese | Phosphorous | Sulfur | Nickel | Chrome | Molybdenum | |

Range | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | ≤8.00-11.0 | ≤18.0-20.0 |

|

Material: S.S 316 | ||||||||

≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | ≤10.0-14.0 | ≤16.0-18.0 | ≤2.0-3.0 | |

Product Picture:

Other types spider in A 200 Series:

A220-4

A220-2

A220-1

A220-21

Project Picture

- Q:250 type curtain wall glass connection pawls how much punch

- Specifically according to the use and the thickness of the glass with the corresponding fitting, generally can open 40 ~ 50mm hole on the OK, the specific best to consult the supplier to clear the relevant parameters and then open the hole, there are holes to open a little So easy to adjust when the construction.

- Q:How to distinguish between the claw is 220 series or 250 series

- Specifications vary in size

- Q:Curtain wall decoration line junction how to take a good connection

- With a strong bond strength, crack resistance, anti-hanging, freeze-thaw resistance, waterproof and other effects. Easy to use.

- Q:What is the difference between a curtain wall countersunk connector and a floating head connector?

- First of all, I think you are referring to the point of the glass curtain wall, split the claw kit in the split connector. There is a sort of splashing and splashing.

- Q:Splicing the claws of the claws

- Part of the split jaw pieces with spherical hinge connection, with the ability to absorb deformation, in the security also has a great protection. Four claws, three claws, two claws 90 degrees, two claws 180 degrees, long claws, short claws, K-type claws,

- Q:How many errors can be made by welding the splicing jaws

- To be reasonable at the beginning of the adapter and the steel frame between the contacts designed, I make a simple example: Now there are a lot of steel frame is welded with a round tube, that adapter The base in the production of the time also need to be cut into the arc, so that steel pipe can be better connected to the tube, while reducing the interface of the degree of restraint, and secondly, reasonable arrangement of welding order to reduce the welding stress, Welding at the same time can reduce the heat generated when welding cracks. Welding starting point and the mouth is easy to produce cracks, conditional welding joints should be at the plus arc plate and arc plate. If you can not use the arc plate, the best use of attenuation current arc, and fill the crater. At the same time in the welding process in order to reduce the weld cracks, as far as possible the use of small lines of energy and cross-section of the welding point. If the process of welding found in the leak, if not serious, then gently knock with a hammer may be just fine. To avoid this is best to the workers carefully, in the welding when the cautious point of these problems can be avoided.

- Q:What is the size of the glass I use

- Light steel glass canopy focus on just the material for the light steel, tempered glass rain shed focus on the glass material for the tempered glass, are glass canopy

- Q:How to measure the size of the glass on the glass structure of the steel structure

- The performance of the spliced ??glass curtain wall is ensured by the installation accuracy of the splicing system, such as air tightness, watertightness, shock resistance, load transfer and other important performance indicators. The splicing system is made up of organic connection of splice joints, splicing jaws, splices and other components. It has the functions of glass installation, positioning, curtain wall deformation compensation, etc. It is the core part of the glass curtain wall. After the structural adjustment is completed, according to the control unit controlled by the junction of the installation point to install the connection, the structural offset caused by the installation error, the eccentric seat and eccentric head can be used to correct the eccentric installation of the connection Size less than 3mm, diagonal deviation of less than 5mm, with a laser pointing instrument calibration. At the end of the welding of the splice socket, the positioning of the splicing jaws begins, and the force of the splicing jaws is downward and calibrated with the horizontal scale. The horizontal of the transverse holes is the same. The joint should be checked against the tightness of the thread before the installation. First install the front part of the joint in the glass fixed hole and tighten, to ensure that each of the joints of the liner is complete, so that the metal and glass isolation, to ensure that the force of the glass part of the surface contact, and to ensure that the locking ring locking seal. Splicing jaws for the fixed surface glass, claws and glass between the rubber gasket, the installation within the allowable range, the adjacent two claw center spacing of ± 1.0mm, adjacent two claw center height difference of ± 1.0mm, phase Neighbor three claw level of 1.0mm, the same claw two holes horizontal deviation of 1.0mm.

- Q:What are the specifications of the curtain wall?

- One of the most commonly used prices are generally acceptable to 304 material, corrosion resistance is also strong.

- Q:What is the reason for rusting the claws?

- 1, the surface of stainless steel deposits with other metal elements of dust or heterogeneous metal particles attached to the wet air, between the attachment and stainless steel condensate, the two together into a micro-battery, triggering the electrochemical reaction , The protective film is damaged, called electrochemical corrosion. 2, stainless steel surface adhesion of organic juice (such as melon vegetables, soup soup sputum, etc.), in the case of water and oxygen, constitute organic acids, long time to form organic acid corrosion of metal surface. 3, stainless steel surface adhesion containing acid, alkali, salt substances (such as decorative walls of alkaline water, lime water spray test) caused by local corrosion. 4, in the contaminated air (containing a lot of sulfide, oxide, hydrogen oxide atmosphere), in case of condensate, The formation of sulfuric acid, nitric acid, acetic acid liquid point, causing chemical corrosion. The above can cause damage to the surface of the stainless steel protective film, causing corrosion. So, to ensure that the metal surface is permanently bright and not rusty, we recommend: ① must always clean the surface of the decorative stainless steel scrub, remove the attachment, to eliminate the external factors that cause corrosion. ② There is a 201 and 202 stainless steel in the market is easy to rust in the coastal area, suitable for use in industrial pollution and air corrosion environment. ③ beach area to use 304 stainless steel, 304 material can resist seawater corrosion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Curtain Wall System Short Single Arme Spider A220-11

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products