Countersunk Cap Routel for Spider AT43

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

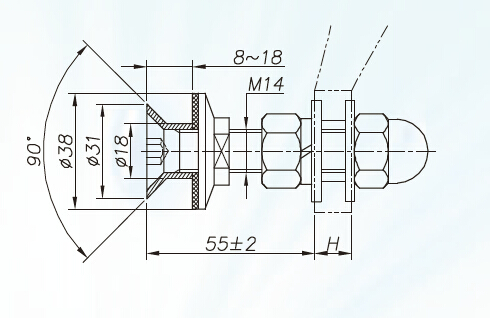

Product Name | Countersunk Cap Routel for Spider AT43 |

Material | Stainless Steel 304/316. |

Finish | Natural |

Glass thickness | 8~18mm |

Bolt Size | M14 |

Max. axial bearing capacity | 4500N |

Max. Radial Bearing capacity | 2000N |

Adjustable angle | ±10 degree |

Min Order | 100piece/ pieces |

Packing | Inner Box + Carton Box |

Supply capacity | 100000 piece/ pieces per month |

Delivery time | 20~35 days after receipt of down payment |

Export market | Asia, America, Europe, Africa, markets. |

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Pictures:

Countersunk Cap Routel for Spider AT43

- Q:How to install the glass canopy

- First welding the installation of light steel skeleton, to paint the steel structure

- Q:Glass curtain wall claw should be how to calculate the size

- Calculate the area of the curtain wall The number of pieces according to the size of the size of your design depends on the size of the glass block is the number of square four For example, the total building curtain wall 200 square feet, I want to design him with an area of 1 square square glass laying, you need to use 200 pieces of glass, and then each piece of glass jaw is 4 is 800 claw pieces!

- Q:The production of curtain wall glass splicing claws of the big brand which several!

- I heard a friend introduced a good with a good, so very good, the price can be, the quality did not say that after all, is a strong sub-brand. Hope to help you.

- Q:I want to open a stainless steel products Monopoly, do not know what stainless steel? Which companies need stainless steel? Which industries need stainless steel?

- Market investigation is clear, if there is a suitable way to do or can do, but now the dry cleaning industry is still very fire

- Q:How many errors can be made by welding the splicing jaws

- To be reasonable at the beginning of the adapter and the steel frame between the contacts designed, I make a simple example: Now there are a lot of steel frame is welded with a round tube, that adapter The base in the production of the time also need to be cut into the arc, so that steel pipe can be better connected to the tube, while reducing the interface of the degree of restraint, and secondly, reasonable arrangement of welding order to reduce the welding stress, Welding at the same time can reduce the heat generated when welding cracks. Welding starting point and the mouth is easy to produce cracks, conditional welding joints should be at the plus arc plate and arc plate. If you can not use the arc plate, the best use of attenuation current arc, and fill the crater. At the same time in the welding process in order to reduce the weld cracks, as far as possible the use of small lines of energy and cross-section of the welding point. If the process of welding found in the leak, if not serious, then gently knock with a hammer may be just fine. To avoid this is best to the workers carefully, in the welding when the cautious point of these problems can be avoided.

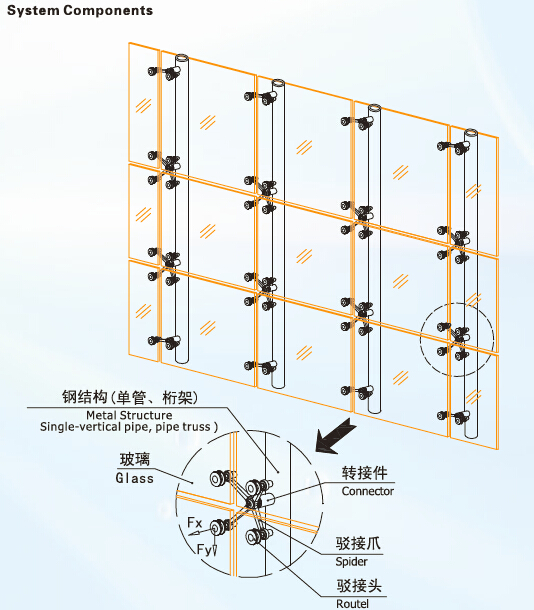

- Q:A set of curtain wall point of the stainless steel access to the claws, including what?

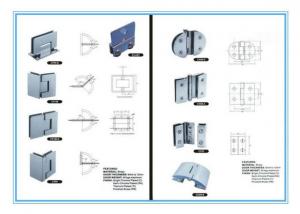

- A set of curtain wall accessories include: such as four claws included, a four paw claw pieces, a adapter base, four split joints, to form a set, in the market are generally complete sets of quotes, but the market The price is expensive outrageous

- Q:What is the difference between tempered glass shed and tempered glass and canopy sunshine shed?

- Light steel glass canopy before dispensing attention to clean the glass, particularly glass edge position at the junction with the gum to avoid secondary pollution, good wind site measures to avoid the influence of the glass plate deformation in structural adhesive curing process. In the process of filling the glue to ensure that the vertical and horizontal joints at the smooth interface, filling the seam, no spill, burr and other phenomena

- Q:What is the meaning of the radial curtain of the glass curtain wall?

- Stainless steel splicing claw glass curtain wall is composed of splicing joints, splicing claws, adapters and other components, the main part of the hook as a support link joints, and transfer load to the fixed support structure system, is connected to the glass curtain wall is an important Accessories.

- Q:Curtain wall windows fixed glass with what accessories

- Conventional shape of the split claws: four claws, three claws, two claws 90 degrees, two claws 180 degrees, long claws, short claws, K-type claws,

- Q:What are the specifications of the curtain wall?

- One of the most commonly used prices are generally acceptable to 304 material, corrosion resistance is also strong.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Countersunk Cap Routel for Spider AT43

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords