Concrete Pump Delivery Pipe With F/M Flange

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Pump Delivery Pipe with F/M Flange

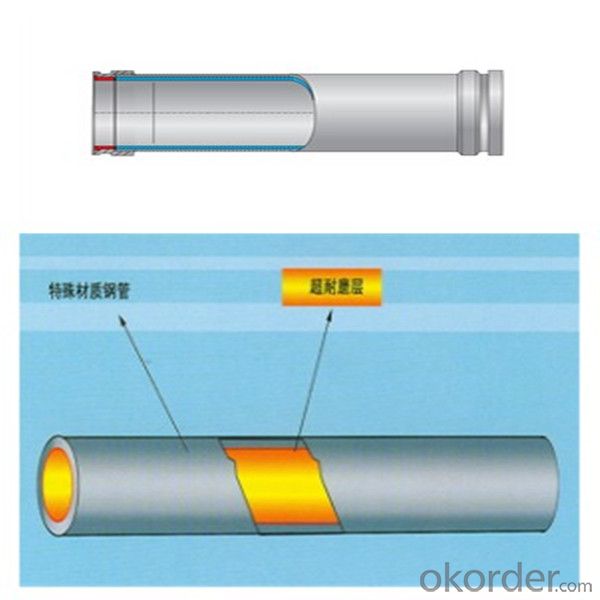

1. Structure of Concrete Pump Delivery Pipe with F/M Flange:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of Concrete Pump Delivery Pipe with F/M Flange:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

3. Concrete Pump Delivery Pipe with F/M Flange Images:

4. Concrete Pump Delivery Pipe with F/M Flange Specification:

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

Name | Data |

Material | 45MN2/20#/16MN/Q345 |

Thickness | According to customer requirements |

Color | red, white , etc. |

Using life | 20.000m³-80.000m³ |

Weight | 43kg,48kg,69kg |

Length | 1-6m, according to customer requirements |

Model | DN125,DN150 |

Flange | SK/ ZX /FM flange |

Painting | Electrostatic Spraying Epoxy Paint |

Welding | Smooth welding between straight pipes and flanges |

Process | High temperature quenching |

HRC | 65 |

5. FAQ:

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

- Q:Before listening to the teacher mentioned that, when the design of components, we should take into account the actual processing capacity of the factory, and some look very simple things, the factory is unable to process! I want to know what the reason is!!!

- The key is and plant equipment and the level of the workers, such as some complex tooling, laser cutting or five axis machining center type of equipment can be processed, it needs to consider the economic.Another example is that the suspension part of mark 206 has a part, but if the layman sees a simple shaft type parts, it can not be nationalized, because its precision requirements are too high and can only be imported, and so on

- Q:Mechanical design practice course, let students do something

- this process appears simple, it is a complex process, such as simple and fitter tools: drill and tapping, need to work in the process of careful experience that is absolutely useless empty talk, feed on illusions. No matter what other enterprises, you have to come up with real technical ability.

- Q:including design originality, manufacturing process, drawing, processing technology, cost calculation, and function

- Estimate is very suspended, needless to say, free of charge, that is, you go to buy, nor necessarily sell you. This is someone else's technical secret, it's not good to go inside for several years.

- Q:Can the bearings used in the design of mechanical equipment be used as part drawings?

- (4459.7 GB/T 1998) for the following provisions: (1) the basic regulations and general characteristics of drawing, drawing, drawing in the various provisions of symbols, rectangular wire frames and contour lines are drawn with thick lines. When drawing a rolling bearing, the size of the rectangular frame and the outline of the outer frame should be consistent with the shape dimension of the rolling bearing (found in the manual) and the same proportion as the drawing. In the cutaway view, when drawing the rolling bearings by the universal drawing and the characteristic drawing, the section symbols (section lines) are not drawn. When drawing with the prescribed drawing method, the rolling body of the bearing does not draw a section line, and each ring can be painted in the same line section with the same direction and spacing, as shown in Figure a. Such as bearings with other parts or accessories (such as eccentric sleeve, tight sets, retaining rings, etc.), the profile line should be in line with the ring profile in different directions or different intervals, as shown in Figure B. Omission is not allowed in drawing without misunderstanding.

- Q:What exactly is mechanical design?

- Mechanical design (machine, design),According to the requirement of the mechanical structure, working principle, motion, force and energy transfer, the various parts of the material and shape size and lubrication methods for design, analysis and calculation and put it into specific description as a basis for the manufacturing process.

- Q:An analog aircraft equipment, in the middle of the two electric cylinder to provide equipment up and down force, two electric cylinders are together and synchronized up and down movement (should be an electric cylinder support force is not enough?) I understand so, so it can only provide the upper and lower forces, the front and left of the three directions, each one of the black rod-shaped structure is how to provide the equipment about deviation, upward and downward deflection of the force? At the same time, how to make these forces achieve controllable effect, complete flight simulation?If cannot send the video address to BIRDLY Baidu flight simulator with complete video, can be seen with me after the detailed explanation, there can also be additional points I'm curious about design of the structure, the answer may take some time and I say that with QQ

- Machinery, derived from the Greek Mechine and Latin Machina, originally referred to as "ingenious design", as a general mechanical concept, can be traced back to the ancient Rome period, mainly in order to distinguish between hand tools. The word "mechanical" in modern Chinese is the generic term for "Mechanism" and "machine" (Machine). Mechanical features are: machinery is a combination of artificial physical components. A definite relative motion between the parts of a machine. So the machine can convert mechanical energy or perform useful mechanical power, is the modern mechanical principle in the basic concept, the modern concept of multi-source Chinese mechanical word from the Japanese "machinery", Japan's machinery products do the following definition of mechanical concept (that is consistent with the following three features called Machine).

- Q:What are the basic criteria for the design of mechanical parts?

- 2. reliable and effective safety protectionAny job of dismantling an old machine is in such a danger that the risk of environmental conditions and the performance of the operator in a dynamic combination is greater when it comes to dismantling the parts of an old machine. As long as there is danger, even if the operator has good technical training and safety education, there are perfect procedures, but also can not completely avoid the risk of mechanical injury accidents. Therefore, a reliable material barrier must be established, that is, to install one or more protective devices, safety devices or other safety measures that are specifically designed to protect the safety of persons. When the equipment or operation of some aspects of the problem, relying on the mechanical safety of their own technical measures to avoid accidents, and ensure the safety of personnel and equipment. Equipment with high risk or high accident rate must be equipped with safety protection device.

- Q:Does the SolidWorks mechanical design engineer paint parts individually or draw parts in an assembly?

- In the overall design of the product, can put each parts of a product are designed, then get the assembly components, after assembly to check whether all parts of the design meets the requirements, whether interference exists, if you need to modify, change are separate parts, and then in the assembly test again until the end, fully meet the design requirements. Since the whole process is down (component), it is impossible to plan the product from the very beginning, and how many parts of the product can be determined only after all the parts have been completed. This method will be modified because there is no prior to the careful planning and effective. This bottom-up design can be used in the case of ready-made products, and in the case of a single product range. But in the new product design or product series rich and changeful circumstances, it seems very inconvenient.TOP-DOWN design refers to the analysis of the finished product, and then down design. The main frame of products as the main component, and the product is decomposed into components, sub assemblies, and then identifies the main component element and its related characteristics, finally understand the relationship between components and internal components, and to evaluate the product assembly. With this information, you can plan and design and grasp the overall design intent in the model.It can manage large components, but also can effectively grasp the design intent, make a clear organizational structure, not only can quickly transfer the design information, in the same design group to achieve the purpose of sharing information, can also transfer the same design information in the design team between different, to the purpose of cooperative combat. Thus, in the early stages of design, through rigorous communication management, can make different design departments synchronous product design and development.

- Q:I designed a great bike with my own mechanical design software. Now I keep it in the computer. What I want to ask isHow do you get these components of the same size, give them the money in the factory, and then make them as planned? Give me a clue, such as magnesium alloy, carbon steel, and so on

- As long as there is enough money, everything is easy

- Q:What kind of software is used in the design of machine parts?

- No, most, only the more, the most suitable for you is your most.If you usually design only 100 of the following parts, use SOLIDWORKIf it is under 1000, using proe is goodMore than 10000, then you use CATIAAs for UG, a little embarrassed, suspended in midair.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete Pump Delivery Pipe With F/M Flange

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords