Cold Rolled/Hot Dipped Galvanized Steel Coil Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Standard:

ASTM,GB,JIS

Technique:

Cold Rolled

Shape:

Round

Surface Treatment:

Galvanized,Color Coated,Oiled,Dry

Steel Grade:

Q195,Q215,Q235

Certification:

ISO,SGS,BV,CE

Thickness:

1.8mm-16mm

Width:

1000mm-1600mm

Length:

according to weight

Outer Diameter:

according to weight

Net Weight:

23mt

Packaging:

Standard Export Packing

Thickness: 0.15-4mm

Width:32-1250mm

Le ID: 508/610mm

Coil Weight: 2-6 tons per coil

Technique: cold-rolled, hot rolled

Zinc Coating: 40-275g/m2

Applications:constractions, building,furniture industry and electrical industry etc.

Production Description:

| Products Name | hot dip galvanized steel coil/Galvanized steel strip |

| Size | Width:32--1250MM |

| Thickness:0.15-4.0mm | |

| Zinc coat | 40-200g/m2(as required) |

| Quality Standard | SGCC SGCD SECC SECD DX51D+Z DX52D+Z |

| Spangle | Zero spangle,regular spangle,normal spangle,big spangle |

| Surface Treatment | chromated and oiled, chromated and non-oiled |

| Application | conatruction,Electrical appliance,furniture,carrying trade,others |

| Workflow | Coil loading→Decoiling→ Pre-straightening→ Buffering→ Fine straightening & feeding→ transverse cutting→ stacking→ cut sheets out |

| package | seaworthy packing, 4 eyes bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and out edge.Other as customer requirement. |

| Production Capacity | 30000 Tons per Month |

| Loading | Per container can be loaded 25 tons to 27 tons. |

| Port of shipment | Tianjin port |

| Payment | TT or 100% Irrevocable LC at sight |

| Delievery time | 15--20days after receiving your deposit or L/C. |

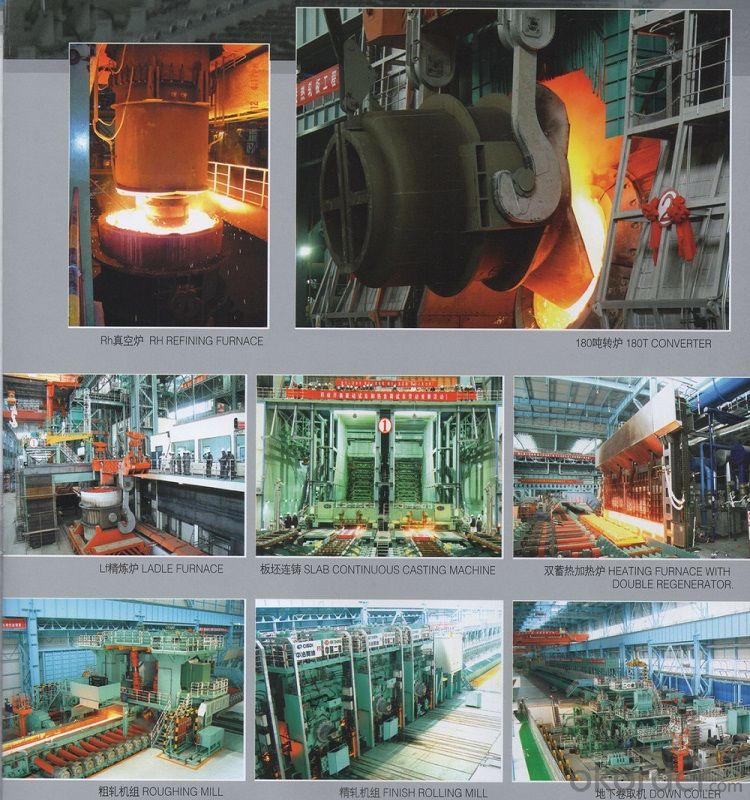

Products Picture

Production porcess

- Q:How are steel coils used in the manufacturing of transmission shafts?

- Steel coils are used in the manufacturing of transmission shafts as they provide the raw material required for shaping and forming the shaft. The steel coils are typically cut into specific lengths and then undergo various processes such as heat treatment, machining, and forging to shape them into transmission shafts, which are crucial components in the transmission system of vehicles and machinery.

- Q:What are the common problems faced during steel coil production?

- During the production of steel coils, several common issues may arise. One of the most frequently encountered problems is the breakage or damage of the coils. This can happen as a result of improper handling or transportation, leading to cracks or fractures. To minimize the risk of coil breakage, it is crucial to adhere to proper handling procedures. Another issue that often arises is coil slippage. This occurs when the coils are not securely stacked or stored, causing them to shift or slide. Coil slippage can cause damage to the coils and potentially lead to accidents or injuries. Therefore, it is essential to have adequate storage systems in place to prevent such slippage. Furthermore, corrosion is a prevalent problem in steel coil production. Corrosion can be caused by exposure to moisture, air, or other corrosive substances. It can result in the deterioration of the steel, reducing its strength and durability. To address this issue, it is necessary to implement effective corrosion prevention measures, such as proper coating or storage techniques. Coil quality issues are another challenge faced in steel coil production. These problems can include inconsistencies in thickness, width, or surface defects on the coils. Various factors, such as improper rolling processes, equipment malfunctions, or material defects, can contribute to these quality problems. Regular quality checks and inspections should be carried out to promptly identify and resolve any issues. Moreover, problems related to coil handling and loading may also arise during steel coil production. Improper lifting or loading techniques can lead to coil damage, resulting in deformations or even accidents. Proper training and education of employees on appropriate handling and loading procedures are crucial to prevent such problems. In conclusion, steel coil production can encounter various challenges, ranging from coil breakage and slippage to corrosion and quality issues. Implementing proper handling, storage, and quality control measures is indispensable in minimizing these problems and ensuring the production of high-quality steel coils.

- Q:I'm sort of a sword maker. You could say I'm an amateur blacksmith. I want to find a dependable source of high-grade steel. I've made a few blades and from what I know about the difference between true steel and cheap steel, I have yet to work with such. All of the metal I have used could not have been true high carbon spring steel because while they are hard, their properties do not reflect that of true steel. I would sincerely appreciate any guidance on where I could order some fine-quality steel so I could produce a truly fine blade.

- Here okorder

- Q:What are the different types of steel coil surface treatments for durability?

- The durability of the material can be enhanced through various types of steel coil surface treatments. 1. To achieve a protective zinc coating on the surface, the steel coil is immersed in a bath of molten zinc in the process of hot-dip galvanizing. This method not only provides excellent corrosion resistance but also extends the lifespan of the steel coil. 2. For indoor applications or when a thinner coating is desired, electro-galvanizing is preferred. This method involves electrodeposition of a thin layer of zinc onto the surface of the steel coil, offering good corrosion resistance. 3. By applying a dry powder paint to the steel coil's surface and curing it under heat, powder coating creates a durable and attractive finish. This finish is resistant to chipping, scratching, and fading, ensuring a uniform appearance. 4. To protect against corrosion, UV rays, and other environmental factors, organic coatings like acrylics, polyesters, or fluoropolymers are commonly applied to steel coils. These coatings not only enhance durability but also improve the aesthetics of the steel coil. 5. Chromate conversion coating involves applying a thin layer of chromate onto the steel coil's surface. This treatment provides corrosion resistance and improves the adhesion of subsequent paint or powder coating layers. Each of these surface treatments offers unique benefits in terms of corrosion resistance, durability, and appearance. The choice of treatment depends on the specific application requirements and the level of protection needed for the steel coil.

- Q:I'm doing a commercial for chemistry and I need to know any kind of chemistry dealing with Callaway Big Bertha Irons. I know they are stainless steel but any more info would help out! Thank you! :)

- Stainless steel is a mixture of metals, each metal is included in order to make up for each others weaknesses. Each metal is included due to a property that is benificial in some way, for instance Chromium is included because it makes the stainless steel 'stainless'. In chemistry a mixture of metals, stainless steel, is called an alloy.

- Q:What are the advantages of using steel coils in the manufacturing industry?

- There are several advantages of using steel coils in the manufacturing industry: 1. Strength and Durability: Steel coils are known for their high strength and durability, making them ideal for various manufacturing processes. They can withstand heavy loads and resist deformation, ensuring that the final product is reliable and long-lasting. 2. Versatility: Steel coils can be used in a wide range of applications across different industries. They are highly versatile and can be shaped, molded, or cut into different forms and sizes, making them suitable for diverse manufacturing needs. 3. Cost-effective: Steel coils are a cost-effective option for the manufacturing industry. Due to their strength and durability, they have a longer lifespan compared to other materials, reducing the need for frequent replacements. This leads to cost savings in the long run. 4. Excellent Thermal Conductivity: Steel has excellent thermal conductivity, meaning it can efficiently transfer heat. This makes steel coils suitable for applications that require temperature regulation, such as in the automotive and HVAC industries. 5. Recyclability: Steel is one of the most recycled materials globally. By using steel coils in the manufacturing process, companies contribute to a more sustainable and eco-friendly approach. Recycling steel reduces the need for raw materials extraction and energy consumption, resulting in a reduced carbon footprint. 6. Corrosion Resistance: Steel coils can be coated with protective layers, such as galvanization or anti-corrosion treatments, to enhance their resistance to rust and corrosion. This makes them suitable for outdoor applications or industries with corrosive environments. 7. Consistency and Quality: Steel coils offer consistent quality and uniformity in terms of dimensions, mechanical properties, and surface finish. This ensures that the end products meet the required specifications and maintain a high level of quality. In summary, the advantages of using steel coils in the manufacturing industry include their strength, durability, versatility, cost-effectiveness, excellent thermal conductivity, recyclability, corrosion resistance, and consistent quality. These benefits make steel coils a popular choice for various manufacturing processes across different industries.

- Q:Are steel coils used in agricultural equipment manufacturing?

- Yes, steel coils are commonly used in agricultural equipment manufacturing. Steel coils are used to create various components such as frames, brackets, and supports, which are essential for the construction and durability of agricultural equipment. The strength and versatility of steel make it a preferred material choice for manufacturing agricultural machinery.

- Q:No. Not Stainless steel, I mean STEEL.Not a specific type, but STEEL.Thanks. xo

- Steel is mostly iron. However, it is an alloy or solid solution, or mixture of iron and other metals or sometimes carbon. All steel is a mixture. there are many varieties.

- Q:How are steel coils protected against moisture and humidity?

- Steel coils are typically protected against moisture and humidity through various methods such as applying a protective coating or wrapping the coils with moisture-resistant materials, such as plastic or wax paper. Additionally, storing the coils in a dry and controlled environment, such as a warehouse with proper ventilation, helps prevent moisture absorption.

- Q:I have steel on my 9.5 ti now.. ive heard about synthetic being stronger but it snaps when it hits something sharp.. opinions people?

- Steel is more dangerous, both in a fatal metal whip way and a metal splinters in my hand way. Steel weighs more. So why would anyone continue to use steel? Cost and care. Care: Steel can sit for years without having to worry about dry rot (as long as it's not out in too horrible of weather conditions). Steel is much more resistant to fraying. You don't have to baby steel so much to keep it in good conditions. Cost: As of right now, steel is less than half the cost of synthetic. A synthetic rope can cost as much as many electric winches which include a steel cable. I find that I don't use my winch nearly enough to warrent the extra care or cost of a synthetic. The weight savings would be nice, but I kind of ruined that a long time ago with the winch bumper, rock sliders, plate steel fenders/flares, belly armor and frame plating.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold Rolled/Hot Dipped Galvanized Steel Coil Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords